The ventilation system of the room is a complex structure. Its essential component is a ventilation diffuser. He is responsible for the uniform distribution of air throughout the space.

What is a diffuser for ventilation

The diffuser is small in size, but an important element in the design of the ventilation system. Outwardly, it is a housing with a ventilation grill of complex design. What is stagnation of air, drafts will have to be forgotten when the diffuser is installed in the ventilation.

The diffuser is small in size, but an important element in the design of the ventilation system. Outwardly, it is a housing with a ventilation grill of complex design. What is stagnation of air, drafts will have to be forgotten when the diffuser is installed in the ventilation.

Air passing through a conventional ventilation system grill is at the same point. At the same time, air zones with different temperatures are formed in the room. Its function is to protect the duct from the accumulation of dust and debris.

The diffuser functionality is superior to a conventional grill. A diffuser is a structural unit located at the inlet or outlet of the duct. It has special impellers and blades, due to which the air volume is taken evenly, its distribution in the room is optimal. It makes it possible to use a static pressure chamber with openings for small dispersion in ventilation, to change the direction of air movement, its shape.

A ventilation grid should be preferred to a diffuser in the conditions of old high-rise buildings. The ventilation ducts there work on the principle of pressure difference. System outputs are located in the walls. Installing a diffuser will not change anything. However, if you make an air duct under these conditions and hide it in the gap between the false and the real ceiling, the diffuser will contribute to the rapid movement of air flows.

The principle of operation and purpose

Unlike the ventilation grilles of obsolete constructions, the diffuser for ventilation is designed in such a way that the air flows not only pass through it, but mix as much as possible and evenly distributed in the room. This is facilitated by the special arrangement of partitions and blades. The principle applies both when air flows into the system and when it is removed.

Unlike the ventilation grilles of obsolete constructions, the diffuser for ventilation is designed in such a way that the air flows not only pass through it, but mix as much as possible and evenly distributed in the room. This is facilitated by the special arrangement of partitions and blades. The principle applies both when air flows into the system and when it is removed.

The main purpose of the device is the effective distribution of air flows in space. Exhaust diffusers ensure that there is no draft in the room, uneven ventilation, air zones where fresh air does not reach.

An honing diffuser upgrades the exhaust system. Without the presence of an air distributor, exhaust air is drawn in the form of jets. The atmosphere of the room suffers. In addition, the amount of exhaust air passing through the exhaust system depends on a change in the direction of its flow. The air diffuser helps to solve the problem.

Effective ventilation of the room where the place of use of the ventilation diffuser is located. If the air masses do not disperse, the ventilation system only ventilates the area where the air circulates. Using a diffuser, fresh air is distributed according to the vortex principle.

Air flow control is another design purpose. You can eliminate the noise of air walking around the room.

The ventilating air diffuser protects the entrance to the duct and performs a decorative function.

Advantages and disadvantages of diffusers

The use of the device in the air exchange system of the warehouse premises, technical, industrial, commercial facilities is extremely significant.For air exchange in the space of residential premises, ventilation diffusers perform the function of regulating the supply of fresh air from the street and its distribution in different directions.

A ventilation system equipped with a diffuser eliminates the presence of stagnant air. The advantage of the design is the ease of operation and installation. Devices fit well into the interior of the room thanks to the decorative finish and the choice of the model of the desired color. Of the shortcomings, one can only indicate the possibility of a draft, but this problem is solved using a static pressure chamber.

Classification

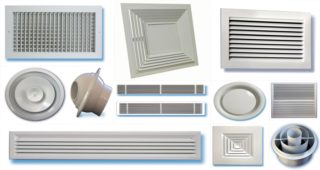

The ventilation equipment market offers various diffusers for ventilation. Between themselves, the models differ in place of installation, shape, material, purpose.

The ventilation equipment market offers various diffusers for ventilation. Between themselves, the models differ in place of installation, shape, material, purpose.

Depending on the material used in the manufacture of the product, there are:

- Metal diffusers for ventilation, the casing of which is made of ordinary or stainless steel or aluminum. Steel models of the ventilation diffuser are not recommended for use in air conditioning systems. Condensation is not compatible with the durability of the air conditioner. In other cases, the metal cases of the diffuser guarantee its strength and durability. Models significantly superior to plastic counterparts in weight and price.

- The plastic version of the case is the most common. It is light weight, affordable price. The choice is diverse in design, shape and color, not inferior to metal counterparts with its consumer characteristics. Resists corrosion.

- Outdoor wooden grill is in demand and fits the design of baths and saunas.

For private households, plastic structures are more often purchased. Metal models are always placed in production facilities.

The diffusers of the ventilation system are round, square, rectangular.

Depending on whether diffusers enter or remove air, they are of the following types:

- Supply air diffusers. Attach to the opening of the duct supplying fresh air from the outside;

- Exhaust models act back to the supply analogs, respectively, are connected to the exhaust exhaust system;

- A universal option is the supply and exhaust ventilation diffuser. It can work on the inflow and outflow of air. But, as a rule, universal models work a little worse than those designed specifically for supply or retraction.

- Combined devices have two openings in the housing for simultaneous connection to exhaust and supply air ducts.

The ventilation diffuser can be installed in three places: on the ceiling, on the wall, on the floor. In accordance with this, they distinguish between ceiling, floor and wall models. Floor diffusers are used very rarely when forced ventilation passes through the basement. Wall designs are also rare. Ceiling models are mainly common in practice.

Design Features

Different in the method of attachment and purpose, the models have narrowly targeted design features. Distinguish:

Different in the method of attachment and purpose, the models have narrowly targeted design features. Distinguish:

- Vortex models are in demand in rooms where fast air exchange is important. For example, a bathroom, kitchen, toilet. The design increases the flow rate of air, its high-quality mixing. This is achieved by a special radial arrangement of jumpers. The air flow passing through them swirls like in a funnel. The internal design of the ceiling vortex model usually has the shape of a cylinder, a lattice of any shape with holes located necessarily around the circumference. It can be equipped with an additional impeller behind the grille. If the impeller is movable, this makes it possible to control it by choosing the rotation speed, of which there are several.

- The so-called slotted diffusers are structurally distinguished by the presence of slots through which air enters.Their number varies depending on the model from 1 to 6, the height is from 0.8 to 2.5 cm. These models are mounted in suspended ceilings, may have a function of the direction of air flow. Models are in demand for small rooms, where the need for low or medium power ventilation system. Models may have the ability to adjust the direction of air movement (like air conditioning blinds). They can be of any shape, including narrow and long.

- The inkjet model has a supply air diffuser. There are standard and movable designs. Their feature is that fresh air enters in the form of jets, while increasing the range and speed of its supply.

- Perforated models can work both for supply and for air exhaust from the room. They are equipped with many small holes through which air passes, evenly and balancedly distributed in space.

Adjustable models of air diffusers have in their design sliding plates with which you can change the throughput. They are also called anemostats. Adjustment takes place by turning clockwise or vice versa the central part of the device. In this case, the movably fixed lamellas close or open the air movement paths.

If an air diffuser is part of an expensive and complex climate monitoring system, it may have sensors that analyze the composition of the air.

How to choose a diffuser for ventilation

For a specific ventilation system, the diffuser is selected based on several requirements:

For a specific ventilation system, the diffuser is selected based on several requirements:

- Section Dimensions This parameter must match the diameter of the duct to which the product will be attached.

- The second important requirement is the conformity of the product throughput to the needs of the equipped living space.

- The material of the case must correspond to the nature of the room and the temperature of the air passing through it. If the product will be located outside, it is better to choose a diffuser model with a metal case, if inside - the plastic version is suitable. In this case, the material of the ventilation duct should be taken into account. Plastic will fit plastic, metal to metal.

- The product range manufactured by industry has many decorative solutions. The choice of a diffuser according to this criterion is possible in order to match the style of the room or the taste of the buyer.

Mounting Methods

Three methods of connecting the diffuser to ventilation are practiced:

Three methods of connecting the diffuser to ventilation are practiced:

- Into an existing vent in the wall;

- To rigid or flexible duct material

- Use as an intermediate link between the product and the internal ventilation outlet of the static pressure chamber.

All models of the air diffuser are structurally equipped with means for fixing upon attachment. These are latches or holes for self-tapping screws.

When attached to a rigid material, the design and input product parameters must match so that the product can be installed in the opening. A tee splitter is used, which is inserted into the ventilation pipe. The device is connected to the third, free output. In this case, the tee outlet is selected the size necessary for the device. To make them convenient to connect. Reliable fixation will be indicated by latches, which produce a characteristic sound when locked.

For suspended ceilings, fastening takes place by the type of recessed fixtures. Large weight models are installed using suspensions or pins to the real ceiling or self-tapping screws.

When connecting the diffuser to a soft metal sleeve or corrugation, the flexible metal end is pulled out of the ventilation duct first. Next, the product is connected to it. Then the corrugation returns back to the hole, followed by the diffuser. The end of the input will end with a characteristic click, which means the latches are triggered.The diffuser should connect evenly to the hole in the ceiling or wall. Slots should not remain.

The pressure chamber or adapter suppresses too active ventilation. But it is mounted in a sufficiently large gap between the real and the false ceiling. The fact that they "steal" the height of the ceiling is a disadvantage of their application. The plus is the lack of drafts. The principle of its beneficial effect in uniform mixing in the tank of the air flow chamber and its smooth supply through the surface of the grate.

Externally, the structure is parallelepiped, the hole for the diffuser is located below. Side or top is a hole for the ventilation pipe of various sizes.

Adapters come in different models: with a removable filter, with a rotary valve, with an air mass divider. Standard adapters are made of plastic or steel.

In the ventilation system, diffusers perform a certain important function. Often they are considered insignificant elements of the system. But this opinion is erroneous, because the correct organization of the air flow, for which this element of the system is responsible, determines the functionality of the system as a whole.