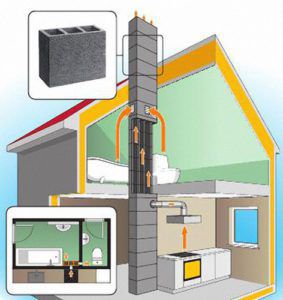

During the design of any home, due attention should be paid to the ventilation system. If it is improperly installed, it will not be possible to maintain a normal room temperature. In addition, the level of humidity will be constantly overestimated, which in turn will lead to the formation of mold and fungus on all surfaces in the house.

Features of arranging ventilation ducts

Today, ventilation ducts are often equipped with metal. But experienced craftsmen prefer brickwork. Brick ventilation shafts are usually located on the inside of the supporting wall of the structure. In this case, the cross section of such a shaft should be at least 1 in 1/2 of the brick or 1/2 in 1/2.

It is best if the device of such a system is carried out from the very beginning of construction. For construction, it is best to use a solid brick. If there is no opportunity to purchase it, then the facing option will be an alternative replacement.

The use of silicate brick is not allowed, since it has a low indicator of resistance to temperature extremes.

The main criteria for the installation of the ventilation duct

When constructing a ventilation shaft, it is imperative to take into account some points that will allow you to perform all the work correctly.

- In the event that the shaft is located in the immediate vicinity of the ridge, the exhaust opening should be 50 cm above it.

- If the hole is located at a certain distance from the ridge, then they can be made at the same level.

- When arranging a kitchen, it is imperative to make a shaft at least one meter high.

- the height of the ventilation duct above the roof is most often made one meter. But if necessary, this indicator can be increased to two or more meters.

Parameters to watch out for

The construction of the canal must strictly comply with the existing technical regulations. The operation of the channels should be carried out at any temperature indoors and outdoors. Processed air must be removed from the premises at any time of the year.

Ventilation shafts must be in rooms where there are no windows - bathrooms, toilets.

There are rules regarding sizes. For example, the cross-section of the channel should be at least 0.016 sq.m. The wall thickness should be at least 100 mm. So that there is no resistance to the passage of air masses, the cross section of the channel should be the same throughout the entire length. All seams on the brickwork must be fully smoothed.

The ventilation ducts must be positioned strictly vertically. Acceptable is a deviation of 30 degrees.

So that the functionality of the mine does not decrease throughout the year, it must be protected from a sharp temperature drop. Therefore, thermal insulation must be carried out using suitable materials.

Masonry is subject to special requirements. The minimum distance to door and window openings should be 40-45 cm. With a wall thickness of up to 38 cm, the brick lies in one layer, with a thickness of more than 64 cm in two.

Preparatory work

Masonry brick ventilation system is quite a complicated process. But subject to all the rules and recommendations, the work can be done independently. To begin with, it’s worth preparing all the necessary equipment:

- trowel and grater;

- mallet and putty knife;

- plumb and construction level;

- hammer.

As for materials, only high-quality products should be used for masonry. First you need to choose the right brand of cement. The sand should be clean, free from clay and other debris.

Completing of the work

The solution for the brickwork of the ventilation shaft should be the same as in the construction of load-bearing walls. A proportion of 1 to 3 should be used, for one part of cement three parts of sand.

When choosing sand, you must give preference to pure material. A low grade will not allow to prepare a high-quality solution, which in turn will lead to a weakening of the entire structure. In this case, the sand should be dry. Using wet material will require less water. Cement must be at least M500 grade. It has good ductility and high strength. It is necessary to check its expiration date, it is strictly forbidden to use an expired product.

Having prepared all the ingredients, they need to be mixed in a dry form. Water is introduced into the solution in small quantities, while it is important to control the consistency. To do this, you can tilt the container in which the solution is prepared. If it does not pour over the sides, then the necessary consistency is achieved.

The most popular ventilation duct today is made with double brickwork and a strictly vertical square course.

This design guarantees the most efficient ventilation system that will fulfill its purpose at any time of the year.

Work begins with preliminary marking, which allows you to accurately place the ventilation element. To make a template, you can use plywood or thick cardboard.

Brickwork starts from the corner of the wall. The device of the first channel can be performed when 1.5 - 2 bricks are laid. Between the channels, you must leave a distance of 1 brick wide.

Brick laying is carried out end-to-end.

All solution on the inside of the channel must be eliminated. Otherwise, after a while it can fall off the wall and thereby clog the shaft. Do not forget about such a moment as linking. Each new row should be done with mixing. Seams should not be above each other, this will weaken the structure.

In the event that a chimney is located in close proximity to the ventilation shaft, it is imperative to make a solid type of masonry of silicate brick.

Negative moments and how to eliminate them

A significant disadvantage of brick ventilation is the loss of heat. This occurs along with the output of the exhausted air in the room. This moment can be prevented if a small bend is performed inside the structure. This design solution will minimize heat loss.

To implement this, bricklaying in one place must be done with a “ladder”.

To prevent the formation and accumulation of condensate in the ventilation duct, it is worth taking care of high-quality thermal insulation. Today there is a huge amount of materials that can be used for this purpose. If a heating device is connected to the ventilation duct, it is worth choosing fire-resistant heat-insulating materials. At the construction stage, thermal insulation can be fully replaced with brickwork. In the event that the temperature drops below -30 degrees, then the masonry should be made in 2.5 bricks. For the southern regions, laying of 1.5 bricks will be enough.

Given all the points, you can equip a ventilation duct that will last a long time, while its functionality will remain at the highest level. It is also not necessary to carry out regular maintenance work related to cleaning the ventilation shafts.This will help maintain system performance at any time of the year.