Thermal insulation is one of the mandatory stages in the construction of a residential, industrial or technical building. It allows you to extend the life of the building. Among the wide variety of materials, insulation Izovol stands out. It has a different density and shape, but invariably qualitatively performs its functions.

Features of production technology

Insulation Izovol is made from basalt rocks. For production, modern equipment is used that complies with state standards. First, the rock is molten to a liquid state in gas-melting furnaces, which ensures high quality of the material obtained.

The fibers undergo a centrifugation and blasting procedure, which makes it possible to achieve the correct shape of the insulation and its uniform density over the entire area. Between them remain air layers, so the appearance of bridges of cold is excluded. The mineral wool is soft, hard or semi-hard to the touch. The material production process is fully automated.

Advantages and disadvantages

The popularity of Izovol mineral wool is dictated by a large number of product advantages.

The popularity of Izovol mineral wool is dictated by a large number of product advantages.

- Ecological cleanliness: the insulation is made from natural raw materials, so it will not cause harm to health. Even when melted, it does not emit harmful substances into the atmosphere, since it does not contain them.

- Low level of thermal conductivity, due to which a favorable atmosphere is created in the room both in winter and in summer.

- Resistance to biological factors: the material is not spoiled by rodents, insects, fungus or mold does not appear on it.

- Good soundproofing.

- Easy installation. Due to the good flexibility of the mats, they are easy to use even in hard to reach places.

- Preservation of properties and shape even with prolonged heavy load.

- High vapor permeability. No condensation will build up on the walls.

If the installation rules are followed, the material will retain its shape for a long time. The operating life declared by the manufacturer is more than 50 years. However, the product has disadvantages: high cost, the need to use protective clothing and devices when cutting plates, since its small particles can get into the respiratory tract, on the skin, causing an allergic reaction.

Specifications

Insulation for walls Izovol has a good level of sound insulation. It extinguishes sounds of any frequencies. Even loud noise in the room will not be heard, but instead a slight vibration will be felt. This property is ensured by the high density of the material.

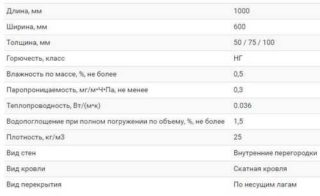

Product Specifications:

- Density: 50-200 kg / m3 This quality can be obtained by using sealing additives in the manufacturing process. They are organic in origin. The value of the indicator is affected by the number of air layers.

- Melting point: 1200 degrees. The material does not burn or smolder. This quality allows the use of Izovol for insulation of saunas, baths, industrial workshops, garages.

- Moisture absorption: 1% when the sheet is immersed in water for a day. The high density of the product does not allow it to absorb moisture. Sheets repel her.

- Vapor permeability: 0.35-0.5 mg / mchPa. Steam can freely migrate inside the insulation boards, so moisture does not accumulate in it or on the walls. The material may be used for the production of facade sandwiches.

- Resistance to the influence of acids and alkaline substances.

- Compressive Strength: 30-85 kPa.The product is resistant to mechanical damage, vertical loads of a temporary or permanent nature. The material does not deform over time.

Thanks to these characteristics, the insulation has a wide scope. However, so that the material does not lose its functions before installation, it must be transported to its destination in a closed transport, while the height of the stacks should not be more than 2 m.

Density and Dimensions

The market offers materials of different densities, thicknesses and sizes. These parameters directly affect the price of the product. The product is sold in the form of plates or rolls. The density of different types of insulation ranges from 20-200 kg / cubic meter. As for the dimensions of the sheet, the thickness is from 5 to 10 cm, although if necessary the manufacturer produces material with other parameters. The standard dimensions of the plates are 1 * 0.6 m.

Fields of application

When using Izovol insulation, technical characteristics play a key role, as they determine the scope of the material. It is popular in private and industrial construction:

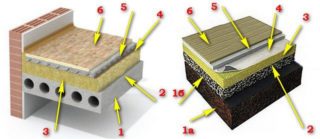

- insulation of the external surfaces of the walls of private houses and multi-storey buildings (even under wet plaster);

- laying on the floor from a log, or under a concrete screed, if the sheets are characterized by high density;

- insulation of attics, loggias balconies from the outside and inside;

- roof insulation, regardless of its type, design, and roof manufacturing material;

- interior decoration of ceilings, walls;

- insulation of agricultural or technical premises, verandas, terraces.

In addition to insulation of structures, the product is suitable for insulation of ventilation ducts, heating pipes or water supply on the street.

Range of heaters Izovol

Recently, the Isobel product has gained popularity. Heater is available in several versions: Izovol L-25 and Isobel P-75. They have a relatively low cost, but good technical performance. The material is used for insulation of internal walls, partitions, ceilings, roofs of various sizes and shapes, ventilation shafts, water pipes and heating mains. Isobel has a high density, so it is not afraid of mechanical damage, the influence of biological or chemical factors.

It is allowed to use the material as the main or additional insulation. It is suitable for finishing panel structures, frame houses. If the surface will not be loaded, a lightweight version of the product with a density of 20 kg / m3 is used.

Izovol ST

The material is suitable for insulation of the external and internal surfaces of walls, as well as thin or multilayer partitions. Often used in the manufacture of ventilated facades, sandwich panels. A common option is the product S-50. The thickness of the plates is 5 cm, 8 cm, 10 cm, but if necessary, the manufacturer can change this value to 25 cm. Heater is sold in packages of 4-8 pieces. Its standard sizes are 1 * 0.6 m. The density of the mats varies from 60 to 90 kg / m3.

These plates are made from thin basalt fibers, so they do not burden the structure. The lightweight version is acceptable for partitions for which a large load is not provided.

Izovol K

Such stone wool is designed to insulate roofs where composite materials that are resistant to ignition are required. It is suitable for insulating flat roofs. The product is convenient to use, since it has small dimensions: 1 * 1.2 m. Thanks to such dimensions, the insulation process is accelerated, a significant area is processed in a short time. Roofing material can not damage the mats, as their density varies between 100-175 kg / m3. Sheets are not deformed and do not bend.

Izovol HF

The specified material is characterized by a high level of density and is used in single or multi-layer insulating pies for roofs. Moreover, Izovol is laid on top of other materials. It withstands strong mechanical loads without losing its original qualities and shape. In addition to insulation, mats perform an additional function of protecting the roof structure from ignition and the spread of fire. It is allowed to use sheets for roofs without using cement screed.

Izovol In

This type of Izovol is lined with fiberglass, which allows you to equip the insulation of the ventilation ducts. These mats are used as additional wind protection for wall panels. The product is used for the manufacture of ventilated facades. The density of the plates is 50, 70 or 90 kg / m3. Other characteristics are similar to those of wall mats.

Izovol f

This brand is characterized by a very high density: 100-150 kg / m3. The thickness of the material is 4-25 cm. The product provides excellent sound and heat insulating qualities. Izovol of this type, like its other varieties, is resistant to ignition, as well as moisture. It is intended for insulation of facades, which will be covered with plaster.

Izovol P

Among the advantages of this variety of Izovol stands out the maximum level of rigidity. Used material for insulation of basements and floors. Sheets well tolerate static and dynamic loads. They are allowed to lay any floor covering, as their density is 175 kg / m3.