When choosing a heater, one of the main parameters is the economical energy consumption. Conventional models can provide a fairly comfortable temperature level, but at the same time fuel consumption will be maximum. Heating boilers for long burning wood and solid fuel are free from this drawback. This was made possible thanks to significant changes in design.

The principle of operation of boilers

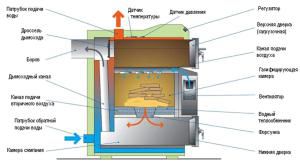

A traditional solid fuel boiler is a design in which there is a combustion chamber, an ash pan and a heat exchanger for connecting to a heating system. To maintain the combustion process, air is supplied to the furnace through an ash pan. In this process, the combustion of fuel occurs very quickly. Heating boilers for long burning wood work on a different principle.

Additional elements are added to it, which ensure the flow of air from the room. Moreover, they differ in intensity and purpose. This innovation directly affects not only fuel consumption, but also the temperature mode of operation of long-burning boilers for a water heating system.

The specifics of the operation of such a heating device is as follows:

- The size of the loading chamber is much larger than that of conventional boilers. This is necessary for the maximum load of solid fuel - firewood or coal;

- After laying the energy source is set on fire and the door closes. At the same time, the air flow does not provide full combustion, but smoldering, while directing the formed gas into the combustion chamber of a long-burning wood-burning heating furnace;

- Here, an intense flow of oxygen provides a special nozzle. The gas ignites and a large amount of heat is released.

The ash pan in this design serves only to remove excess mineral waste from the loading chamber.

It is noteworthy that, depending on the direction of the air flow to smoldering firewood, gas can flow both up and down. The choice of direction helps to optimize the design of a long-burning furnace for water heating. Their varieties and principles of work must be considered.

Types and design features

The process of burning non-solid fuel, and the formed gas as a result of its decay is called pyrolysis. This is the thermal decomposition of inorganic and organic compounds, resulting in the formation of gas. An important difference from traditional burning is the lack of open flame. If this is effective home heating, a long burning stove is often called pyrolysis.

When choosing this heater, you must pay attention to the following parameters:

- Loading chamber volume. The larger it is, the longer the long-burning heating boiler will run on one batch of fuel;

- Air supply mechanism. It can be an electric motor, or an air channel with a natural influx of air masses. The latter is less effective, however, such heating boilers for wood with long burning are completely independent of the availability of electricity;

- The method of regulating the intensity of the smoldering fuel. For non-volatile structures, this is a mechanical thermostat that closes and opens the air supply door. Long-burning solid fuel heating boilers with an electronic control system respond more quickly to temperature changes in the combustion chamber.

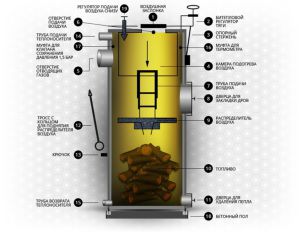

Non-volatile designs can be done with your own hands.But for this you will need an accurate installation diagram, special materials and tools. An example of such a home-made boiler is the invention of the Lithuanian master - the heating installation Stropuva.

The uniqueness of this installation lies in the patented telescopic air supply pipe, which lies on the wood. As they burn, it falls below the influence of gravity, creating an optimal flow of oxygen.

In practice, it is rather problematic to make a heating boiler using long burning wood and solid fuel. Even a small error can cause a sharp drop in the efficiency of the entire installation.

Operational features of a long-burning boiler

Despite the obvious advantages, each long-burning wood-fired heating boiler has a number of specific characteristics. First of all, the low temperature regime of the heating system. Compared to the energy released during open burning of fuel, wood gas has a lower energy intensity. Therefore, the temperature regime of such a system is 70/50 or 60/45 ° C.

Long-burning factory boilers for water heating are characterized by a good value of efficiency - up to 80%. This is one of the highest rates for solid fuel heating equipment. However, along with this they have large overall dimensions, which is explained by the specifics of the design.

To select a heating boiler for solid fuels, long burning should be guided by its rated power.

A simplified calculation is performed using a simple ratio - 1 kW of boiler energy must be spent on 10 m² of a heated room.

If you make a home-made heating stove for long burning on wood, you must first equip the foundation for its installation. The same applies to boilers with a large weight (from 400 kg). Moreover, the foundation should not be connected with the general.

Overview of boiler manufacturers

Dakon boilers

Currently, there are several companies specializing in the manufacture of long-burning heating boilers. One of them is the Czech production association Dakon. A special place in the assortment is occupied by the KP PYRO F model.

Depending on the needs, the buyer can choose an analogue of a continuous combustion furnace for water heating with a capacity of 21, 26, 32 or 36 kW. A design feature is the use of modern insulating materials for the housing. This ensures maximum efficiency, since energy is concentrated only on the heat exchanger.

In addition, the following characteristic features that Dakon long-burning heating boilers with wood have are noted:

- Convenient system for regulating the air supply to the combustion chamber. To improve this feature, you can optionally install a fan;

- Possibility of using firewood of large diameter - up to 130 mm;

- The large frequency of ash removal is 5-7 days of continuous operation. This model of long-burning boilers for water heating is designed for 12-15 hours of continuous operation on one tab of firewood.

The cost of the most popular model is 90-110 thousand rubles, depending on capacity.

Stropuva boilers

About heating boilers operating on solid fuel in the long burning mode of this brand, there was a mention above. However, it is worth noting that the manufacturer in a short time from a small workshop was able to grow into a full-fledged supplier of solid fuel equipment.

The range includes small models with a capacity of 7 kW, designed for summer cottages. For large areas, you can choose powerful 40 kW equipment. When organizing home heating using this long-burning stove, you can not think about connecting electricity. All models are completely non-volatile.

However, consumers have noticed several disadvantages that are characteristic of heating boilers operating in the long-burning mode:

- Chimney soot clogging. The relatively low temperature contributes to the formation of soot on the inner surface of the chimney. Therefore, work on its removal should be carried out more often than with classic heating appliances;

- Firewood moisture requirements. For normal heating of a long-burning stove connected to water heating, the humidity of the wood should not exceed 20%.

But even with these small flaws, the popularity of long-burning boilers is growing every year. When organizing heating using such heating devices, special attention is paid to pipes. The material of their manufacture should have a minimum coefficient of thermal conductivity. This will help reduce heat loss during operation of the entire system.

For fans to do everything with their own hands, a video about a self-made boiler of long burning will be useful: