For any closed heating system, it is necessary to provide a device to compensate for the expansion of the coolant. This is necessary to maintain the integrity of the pipes, radiators and boiler heat exchanger. In addition to the standard air vent, membrane tanks for heating systems must be mounted: installation, calculation, the principle of operation of which directly affects the heating efficiency of a residential building.

Appointment and features of membrane tanks for heating

First you need to know the functional qualities of this device. When water is heated in the pipes, a natural expansion and pressure increase occurs. If the value exceeds the normalized value, a stabilization mechanism is needed. For this purpose, membrane tanks are designed for heating systems, which may differ in technical and structural characteristics.

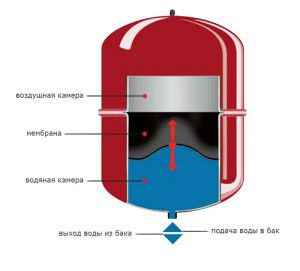

They are a sealed container, divided into 2 areas - water and air chambers. Between them is an elastic membrane. To connect a water supply, a corresponding pipe is provided, and a pressure injection system is located in the air chamber. The principle of operation of the expansion membrane tank for the heating system is to increase the net volume as a result of the displacement of the elastic membrane towards the air chamber. To do this, connect the water pipe to the heating pipe, and create a pressure in the air chamber, the value of which should not exceed the nominal value for the heating system.

Installing a membrane tank in a heating system has the following advantages:

- Automatic stabilization of critical expansion of the coolant;

- No water loss due to evaporation;

- Possibility of installation both for a system with distilled water, and with antifreeze;

- Simple installation and replacement of the membrane in excess of its useful life.

But how to choose a membrane tank for heating, the principle of which is so simple? To do this, you first need to familiarize yourself with its varieties.

The membrane tank for heating is similar in principle to a similar one for a water supply system. But the design of the latter is not designed for high temperatures. Manufacturers mark them in blue, and heating - in red.

Types of membrane tanks

At first glance, the design of the device is quite simple. However, for various heating systems with specific technical characteristics, the correct model of the membrane expansion tank for heating should be selected. Consider the most popular models that can be installed in both the domestic and industrial systems.

Fixed tank

Their feature is that the membrane tank for heating according to the instructions is not collapsible. those. the elastic membrane cannot be dismantled and replaced with a new one. Despite this seemingly disadvantage, these models have one significant advantage - affordable cost. That is why they are installed for small heating systems with relatively stable pressure in the pipes. Often, the calculation of a membrane tank for heating involves a constant indicator of the pressure in the air chamber, which the manufacturer indicates additionally. But if there is a probability of exceeding the critical exponent of the expansion of the coolant, it is necessary to establish a different type of design.

Replaceable diaphragm flanged

To install a new membrane in the design, a flange is provided on which it is mounted. Thus, it is possible to regulate the volume of the membrane tank for heating, to install elastic lotions with different indicators of elasticity. Similar models are mounted for heating systems with a high probability of excess pressure in the pipes. This primarily relates to solid fuel boilers, where it is not possible to quickly adjust the level of water heating. Tanks can be made of horizontal and vertical type. To replace the membrane, it is necessary to remove the flange, dismantle the old one and install a new one in its place. The most popular manufacturer of such models is Wester, a membrane tank for heating, which can be found both in a small private house and in the heating system of a production workshop.

The useful volume of a membrane heating tank depends on its shape. For large systems, it is best to choose cylindrical structures, and flat models will be optimal for heating with a small pipe length.

Calculation of the membrane tank

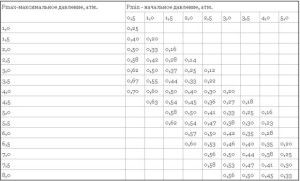

However, the choice of design is not the only parameter of the membrane tanks for the heating system. An important quantity is the volume in one chamber, namely, its fill factor. The correct calculation of the membrane tank for heating is impossible without the following parameters:

- The total volume of coolant in the system is C. As you know from the school physics course, when the temperature rises for every 10 degrees, the liquid increases by 0.3%. This is what will primarily affect the volume of the tank;

- The maximum and minimum pressure values in the system. Often the critical value does not exceed 5 atm;

- Fill factor (CAP). It directly depends on the pressure indicators in the pipes. In the table you can find the desired value for a particular membrane tank. In the instructions, the manufacturer indicates the nominal value of the fill factor.

The expansion coefficient for water E, which is equal to 0.034 at 85 ° C, should also be considered. Further, the calculation is performed according to the formula. Suppose that the total volume of the heating system is 410 liters, the minimum pressure is 1 atm, and the maximum is 3.5 atm. The fill factor will then be equal to 0.55, and the useful volume of the tank is equal.

This is the optimal calculated value of the volume of the membrane tank for heating. If necessary, it can be changed in the direction of increase, but not more than 15%.

An accurate calculation of the volume of the membrane tank for heating is recommended only after reading the instructions from the manufacturer. It contains all the necessary data for the calculations, as well as possible errors and deviations.

Tank Installation Steps

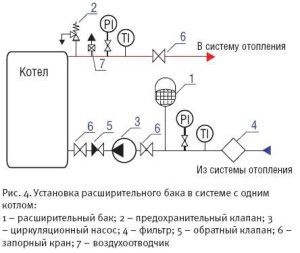

For a qualified installation of a membrane tank in a heating system, it is necessary that the room meets the operating conditions. The temperature in it should not fall below 0 degrees with a stable indicator of humidity. It is necessary to determine the installation location, since the system is characterized by pressure drops during its start-up. Therefore, it is not recommended to install expansion membrane tanks for heating immediately after the boiler on the outlet pipe.

The next criterion is the absence of turbulence in the flow of water, which can simulate excess pressure. It is best to mount diaphragm tanks for heating systems on the return pipe in front of the circulation pump. Installation technology consists of the following steps:

- Insertion into the pipeline. Typically, the diameter of the expansion tank nozzle is 3/4. Therefore, in the return pipe you need to install the corresponding channel with a thread;

- Installation should not be obstructed by objects or system elements. External mechanical load on the tank is eliminated;

- As gaskets, it is best to use paronite models, since they withstand pressure and high temperatures well;

- Membrane expansion tank for heating must be equipped with an air valve. It is necessary to stabilize and adjust the pressure in the air chamber.

Each time you start a closed heating system, an increased pressure indicator will affect the membrane. Therefore, it is recommended to check the condition at least once every 2 years and, if necessary, replace it.

This is a typical installation diagram that does not take into account the features of a particular heating system and its constituent elements. During installation, frequent errors that can lead to improper functioning of the membrane tanks for heating systems should be avoided. First of all, setting the maximum pressure in the air chamber. It should be less than the calculated critical by 10-15%. Otherwise, the membrane will not expand towards the chamber, which will lead to rupture of pipes and failure of the radiators. To avoid this, it is necessary to install a pressure gauge, which is recommended by Wester, whose membrane tanks for heating are characterized by high reliability.

To install a membrane tank in the heating system, make sure that there is no heating tank in the boiler. If its volume is not enough according to calculations, you can mount an additional tank.

Membrane Tank Tips

First of all, it is necessary to determine the design of the membrane expansion tank, designed for heating. If critical pressure surges are not expected, the total coolant volume is small - you can choose an inexpensive model of a fixed type. In all other cases, membrane tanks are needed for collapsible heating systems, since it is much cheaper to change the elastic membrane than the entire structure. In addition, the following factors should be considered when choosing:

- The thickness of the metal body. It should be at least 1 mm;

- Protective inner and outer coating. Since all membrane tanks, designed for heating systems, are made of metal - corrosion processes should not affect their integrity;

- Reduction of heat loss due to an additional insulating layer. The relatively large volume of the water chamber can adversely affect the decrease in water temperature in the pipes. If the design does not provide a heat-insulating layer - it can be done independently using foamed polyethylene or similar material;

- Pay attention to the design. According to the instructions, the membrane tank for heating can be horizontal or vertical type. Installation in a different position is prohibited.

And most importantly, only trusted manufacturers should buy models. These include expansion tanks for heating by Wester. Along with it, Zilmet (Italy), Aquasystem (Italy) and Sprut (China) products are characterized by good quality indicators. Their average cost is from 2 to 5 thousand rubles, depending on the volume.

Despite its good performance, in addition to the expansion membrane tanks of the heating system, a drain safety valve is installed. If the pressure value in the pipes exceeds a critical value even for an expansion tank, the valve will remove excess water.

The video shows another way to calculate the volume of the expansion tank: