Universal insulation foam is the most popular insulation material. It is used in the repair of apartments, the construction of private houses, garages, residential and office buildings. Technical characteristics allow it to be used in various sections of the structure - from the foundation to the roof.

The structure and composition of the foam

Foam production began in Germany in the 40s of the XX century. Gas-filled plastics have a closed-cell structure. A significant part of the volume of the material is occupied by air, it accounts for 98%. The remaining 2% is polystyrene. In the manufacturing process, the polymer granules are foamed and steamed. After drying and pressing, the material is cut into slabs.

The heating costs depend on the thickness of the foam for wall insulation. Manufacturers offer plates with a parameter of 10 to 100 mm. The thicker the material, the less heat loss. To warm houses in the middle lane, polystyrene foam of 40 and 50 mm is used, in cold regions - 100 mm. It is impractical to use the thickest insulation, it is much more expensive than medium-sized products.

Foams and foam for home insulation are made from the same raw materials - polystyrene, but using different technologies. Expanded polystyrene is obtained by treating the granules with steam. Its structure is porous, with many voids. Penoplex is made by extrusion. Plates are dense and durable. The material wins by some technical characteristics, but the low cost of polystyrene in many cases plays a decisive role.

Specifications

The performance characteristics of the material determine its properties and scope. Features of a heater:

- Thermal conductivity. Air capsules provide reliable insulation, the coefficient of thermal conductivity is 0.037-0.044 W / m * K.

- Soundproofing and wind protection. The cellular structure of the material provides excellent sound insulation. When using expanded polystyrene, additional wind protection is not required.

- Water absorption. The rate is 1% during the day. Insulation weakly absorbs moisture.

- Biological inertness. The heat insulator is not affected by mold and mildew.

- Resistance to chemical attack. Alkalis, lime, bitumen, acids do not affect the foam. Material must be protected from oils, solvents and petroleum products.

- Flammability. Expanded polystyrene belongs to the class of combustibility G3. This is a moderately combustible insulation with the ability to self-extinguish.

Using foam as a heater is beneficial due to the long life. It is resistant to low and high temperatures, moisture and mechanical stress.

Features of installation and use

In many cases, the insulation must be placed indoors. This feature is typical for high-rise buildings. Experts do not recommend warming houses with polystyrene from the inside. Due to the flammability and toxic gases released during melting, the material is harmful to the health of residents, can be life threatening. Another minus of warming with polystyrene foam from the inside is the lack of air exchange. Indoor ventilation is required. Inexpensive insulation is suitable for buildings with temporary residence.

Options for external insulation

When preparing a construction project, you need to choose how to foam insulate the house from the outside and how thick the material should be. Slabs with a thickness of 50-100 mm are suitable, their density should be from 25 kg / cu. m. Expanded polystyrene with such characteristics is used for installation on walls with subsequent plastering. This is a wet way. The insulation is fixed on the facade with a special mortar or glue. The plates are staggered. A finishing layer of plaster is applied to their surface, always with a reinforcing mesh.

The second option is a ventilated facade. Polyfoam for insulation in this way is used less often. In this case, it is inferior in functionality to its main competitor - mineral wool.

Installation sequence:

- Preparation - leveling and priming the walls.

- The device of the lathing for the facing material.

- Fixation of heat-insulating plates with the help of special glue and plate-shaped dowels.

- Installation of a ventilated facade - siding, aluminum or fiber cement panels.

Expanded polystyrene during thermal insulation by a wet method will last longer. Under the protective layer of the solution, it does not crumble. The use of foam insulation for ventilated facades increases the risk to human life when a building ignites.

Styrofoam grades and scope

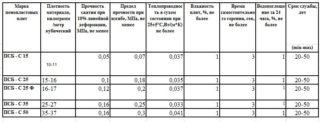

The most common type of foam is polystyrene foam. The material is available in various densities and mechanical strengths. Main brands:

- PPT-10 - low density plates used in multilayer structures.

- PPT-15 - foam insulation for non-load insulation of temporary buildings, containers, wagons. They can be laid on the ceiling, attic.

- PPT-20 and 25 - the material is used for thermal insulation of facades, ceilings, balconies, water and sewer pipes. In frame houses, it serves as the basis for sandwich panels.

- PPT-35 - high density foam is suitable for mounting under the screed. It is used to warm the foundation, floor, storage facilities.

In product labeling, the number indicates density - the weight of the material per cubic meter. In addition, the letter designations tell about the properties of the foam:

- A - flat edge of the plate;

- B - material with an L-shaped edge;

- N - insulation for external use;

- C - self-extinguishing.

High density of the material increases its tensile strength, expands the possibilities of application. Together with indicators, the cost of products increases.

Advantages and disadvantages of polystyrene foam

Before using polystyrene foam boards as thermal insulation, it is worth examining their advantages and disadvantages.

Advantages:

- Low thermal conductivity, allowing you to create an energy-efficient system.

- Polyfoam from all heaters for walls is the most affordable.

- Under normal conditions, it does not affect the human body. The material has no harmful emissions.

- The light weight of the plates simplifies transportation and installation.

- A wide scope of application - insulation is used in the construction of residential buildings, in the construction of industrial facilities, insulation of bridges, pipelines.

- Easy installation accelerates the process of thermal insulation, allows you to perform work without special skills and tools.

- Sheathing the room with foam helps reduce noise.

Disadvantages:

- The main disadvantage, because of which the foam is not recommended for warming houses, is the combustibility of the material. During a fire, toxic smoke poses a threat to people.

- When installing outside the building, protection against ultraviolet rays that destroy polystyrene foam is required. When choosing a finish coat, its low resistance to acetone and other solvents is taken into account.

- The lack of vapor permeability when insulating from the inside leads to dampness on the walls.

- Material is destroyed by rodents. They make nests by cracking plates on polystyrene balls.

Numerous advantages of the material made it a popular insulation material. To protect yourself from possible problems with combustibility, you should buy stoves with the addition of flame retardants.