External insulation of the external wall of a brick house reduces energy leakage from inside a residential building, which reaches 25-35%. Insulation on the front side with a thickness of 10 cm protects against losses similar to one and a half meter masonry of silicate brick. The facade insulation parameters are laid at the design stage, while building materials are saved, the weight of walling is reduced.

The advantages of external thermal insulation

Wall protection is installed inside and out. Internal insulation is done if there is no way to perform external insulation.

The advantages of facial facade insulation:

- regulation of temperature fluctuations, leading to a decrease in deformations and a decrease in the risk of cracks;

- saving the internal space of rooms;

- facilitating the laying of internal communications;

- improving the appearance of the building.

The temperature at which condensation occurs is called the dew point. The phenomenon occurs in the thickness of the wall or on the inner surface - it depends on the technical characteristics of the material and the design of the fence. The position of the dew point is affected by the difference between the internal and external microclimate. Facial insulation shifts the boundary of the condensate to the outer plane, where moisture forms.

Thermal insulation on the front side is difficult to perform if the facade of the building rises to a great height. Installation of scaffolding is required, the labor costs of people for raising materials to the workplace are increasing. Additional mechanisms and equipment are used.

The main characteristics of thermal insulation materials

The market offers many materials for outdoor protection, which vary in quality. The insulation is selected according to the technical characteristics, taking into account the behavior of insulation during humidity, frost, fire, interaction with chemicals.

Some materials are destroyed in extreme conditions, while others are durable. The ecological purity of the insulation and the ability not to harm the environment are important, since toxic substances can be released when the facade is heated by sunlight.

Water absorption coefficient

The parameter is determined by the ratio of the volume of moisture that the material can absorb when in contact with water or when it is in wet conditions, to the mass of a completely dry insulation. The ability of the insulating plates to retain the incoming fluid in the pores matters.

The structure of expanded polystyrene consists of closed pores, so the surface of the material is moistened only from the outside. Mineral wool is absorbed by moisture and loses its heat-shielding properties, so it requires a ventilated space to dry. Material with low absorbency lasts longer since it can withstand a greater number of freezes and thaws.

Coefficient of thermal conductivity

The ability of an insulating layer to transfer heat from one surface to another is called thermal conductivity. The coefficient reflects this property and is equal to the amount of energy penetrating through 1 square. m of a layer 1 m thick, while the temperature on opposite sides differs by 10 ° C.

According to thermal conductivity, materials are divided into classes:

- low (A) - up to 0.06 W / mK;

- average (B) - in the range of 0.06 - 0.115 W / mK;

- high (V) - 0.115–0.175 W / mK or more.

The ability of a heater for a brick house to conduct heat outside depends on the structure, density, moisture resistance and other technical characteristics.

Flammability

Fire resistance (flammability) is the ability of a layer to limit fire and maintain the declared qualities when heated to a boundary temperature. The property is characterized by a flame spread and fire resistance.

These indicators are checked by a fire test according to a standard method and are expressed by the period of time until a condition appears:

- destruction;

- temperature increase + 160˚С on the plane opposite the flame;

- the appearance of through cracks through which the flame emerges or combustion products exit.

Information about the limits is used in the design of house insulation. For structures there are established fire resistance classes (5), the protective layer must correspond to the general characteristics of the building. Mineral wool and foam glass do not burn, extruded foam and sprayed insulation correspond to the fire resistance category G3 - G4. Polyfoam is characterized by a high degree of fire hazard, it is forbidden to use above the second floor.

Density

The indicator is determined by the ratio of the weight of the material to the volume it occupies, expressed in kg / cubic meter. The characteristic depends on the structure and shape of the pores and changes when moistened, heated or cooled. Dense materials are hygroscopic, more durable, porous, better allow steam and air to pass through.

Expanded clay insulation has the highest density, followed by sawdust, foam glass and mineral wool. The minimum density is different for foam and cotton wool. The correct insulation is selected taking into account such a characteristic.

Dense insulation weighs more and creates an additional load on the structure. Better to choose materials with an average.

Sound insulation level

The protective layers are characterized by how they reduce the noise passing into the room from the outside. A quantitative measure of sound insulation is measured in decibels and depends on the properties of the insulation. Porous layers with a cellular structure or randomly spaced fibers are good noise absorbers. An example is basalt wool, foamed types of polymers, felt, vermiculite.

The use of different materials in one design leads to improved sound insulation. For example, the insulation for the walls of a house outside under a brick may consist of two layers, which will increase the absorption of noise from the street. The science of building acoustics distinguishes between shock and air. Air is delayed by an insulating layer, because it is transmitted in the atmosphere. Vibration and percussion sound are transmitted through the supporting structures.

Environmental friendliness

The concept means the ability of the insulating layer to ensure the safety of the environment during operation. Non-environmental materials contain substances that are harmful to health. Some of them begin to stand out from the old layers, others are activated when heated or reacted with chemical reagents.

Harmful fillers and additives:

- formaldehyde;

- styrene, polystyrene, styrene monomers;

- flame retardant borax;

- lime;

- polyol, pentane, dust, bromine.

Mineral wool refers to environmentally friendly insulators, because it is made on the basis of basalt. Extruded polystyrene foam is conditionally environmentally friendly, it is produced chemically, it is recommended to insulate the outer walls. Polyfoam contains volatile conglomerates, not used for internal work.

For external insulation, all types of insulation are used, becausethey don’t contact with people and are closed from the heating by the sun with finishing layers: simple plastering is done or in the form of a fur coat, siding is placed.

Installation complexity

The difficulty of installation, the use of an additional frame for installation determines the choice of insulation. It matters the ability to perform external protection with your own hands by a person without much experience. Making the base of the rails or profile adds to the overall value of the insulation layer.

Polyfoam, expanded polystyrene, foam foam are glued to the wall surface and do not require a bulky frame. Mineral and basalt wool, roll materials require air intake, so a frame with a ventilation gap is made.

Recommended insulation for brick walls

Materials are organic, gas-filled plastics and products from waste from the woodworking industry (sawdust, reeds, straws) are included in the category. The second group is inorganic insulation, the layers are made of mineral wool, plates, glass wool, foam glass, foam concrete, expanded perlite. The third category includes mixed materials.

Styrofoam

Expanded polystyrene foam is produced in bulk granular mass and in the form of plates. The specific gravity of the panels in the range of 10 - 50 kg / cu. m determines the scope of insulation. Material with low indicators is used to insulate the walls of change houses, garages, high-density plates are used for shops, residential buildings, refrigerators, industrial buildings.

Plates are produced with a thickness of 20 - 120 mm, the thermal conductivity coefficient is 0.042 W / mK. For a day, the material absorbs 2.5 - 3% of moisture from the volume.

Extruded Styrofoam

The heater shows low coefficients of thermal conductivity, is resistant to chemicals. Expanded polystyrene is available in several types, but all are durable, absorb little moisture and pass air well.

Mold and fungus do not appear in the layers, rodents do not live. The material protects the walls of the structure from the harmful effects of the environment. Plates with special edges are available in thicknesses of 20 - 100 mm, coefficient. thermal conductivity - at the level of 0.03 W / mK, absorbs 0.2 - 0.45% of water from the volume.

Mineral wool

A popular insulation is available in the form of piercing rolls, mats, plates of various stiffness. The material does not burn, but melts and withstands heating up to + 1000˚С, does not collapse during frost to -185˚С.

Mineral wool is produced in three types:

- Glass wool. The elastic fibrous structure, brittle, is damaged during installation and releases small particles of glass. It is used in industrial insulation.

- Slaggy. Made from waste blast furnaces (slag). It has a low thermal conductivity, but does not tolerate bending during installation. Limited use since absorbs moisture from the atmosphere and destroys metal when touched.

- Basalt (stone) cotton wool. It has fewer negative characteristics, it is used for curved planes, it does not collapse during installation.

It is produced by mats with a thickness of 50 - 100 mm, shows a thermal conductivity of 0.03 - 0.05 W / mK.

Warm plaster

Available in the form of a dry mixture, packaged in bags. There is no sand in the composition, it is replaced by heat-insulating components. Portland cement acts as a connecting element.

Warm plasters contain fillers:

- volcanic rocks, for example, vermiculite or perlite;

- expanded clay crumb;

- sawdust;

- pumice powder or crumb;

- polystyrene foam in the form of grains;

- cork crumb.

Warm plaster is divided into a mixture for external and internal work, depending on the main component and modifiers. For strength, water repellents and reinforcing threads are added.The cost depends on the amount of additives.

Warming Methods

Which method to use is determined by the type of material and its properties. External insulation is done at an air temperature of not lower than 0 ° C, otherwise the composition for wet work may become unusable.

Under siding

Insulation as part of a ventilated facade is a common option, despite the complexity of the work. Heat loss through the walls is minimized due to the fact that the siding finish layer additionally protects from the wind. Waterproofing in the structure of the structure protects the surface from moisture and the insulation performs its functions, regardless of humidity.

Insulation on the frame is used in most buildings, with the help of siding, the appearance of complex and curved facades is improved. The frame is made of a metal profile, which additionally presses the insulating layer. The use of wooden battens in the decoration of the facade is not allowed.

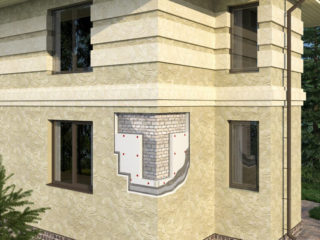

Modern method

Sometimes the protective layer is placed on the outer surface, which will be plastered. If foam is used, basalt insulation in the plates, the material is glued to a plane and additionally attached with dowels with large heads (mushrooms). From above, the surface of the insulation is glued with a reinforcing mesh of metal or plastic, the plaster is applied over the mesh. The layer is glued with the approach of the strips on each other by 15 cm.

If soft material in the form of rolls is used, the insulator is formed by a frame from the profile and sheets of chipboard, OSB are placed on top, which are processed with a primer and plastered on a grid. The processing of the wall is carried out before the sticker of insulator sheets, the surface is leveled and primed.

Warming the house with foam on the principle of "wet facade"

Manufacturers produce systems for the execution of wet facade types. Extruded polystyrene foam with a density of 35-50 kg / cubic meter is used. m. Durable insulation acts as a reliable waterproofing and vapor barrier.

The wet facade system includes materials and components:

- wall primer to enhance adhesion;

- adhesive for fixing the heat insulator;

- hardware for fixing the insulation layer on the plane of the wall;

- reinforced mesh with a mesh of approximately 5 mm;

- dry plaster mix for external works;

- paint on the facade.

Installation of such a system is cheaper than the implementation of a ventilated facade, but regular repairs will be required during operation. The wet facade is intended for private buildings, and ventilated options are suitable for multi-story buildings.

How to apply warm plaster to walls

The work process differs in some features, for example, before applying the composition, it is not necessary to level the plane of the vertical fences. Application itself is no different from working with wet mixes for outdoor use. Warm plasters adhere well to the surface, but reinforcing materials are used to give extra strength.

After drying, the composition passes an air stream, so steam and dampness does not accumulate in the mass, but is discharged out. Acrylic paints can be applied over warm plaster after drying. The insulation layer retains properties longer than mineral wool, belongs to the category of environmentally friendly products.