The decision to install a warm floor under linoleum allows you to create comfortable conditions for walking around the room and improve its heating. The problem of cold floors is characteristic of private mansions and apartments located on the ground floors. Often, even a multilayer cake made of insulation and insulating materials is not able to cope with the dampness coming from the ground. As a result, the concrete floor is covered with condensation and mold. The solution to the problem is heating elements and a heat-conducting topcoat, which can be linoleum.

Is it possible to put linoleum on a warm floor

Decorating the premises with this material is popular in private and commercial construction. This is explained by the numerous positive characteristics of this type of finish. SNiP do not limit the use of flexible coating in residential premises. The prohibitions apply only to objects that are dangerous in terms of the possibility of fire.

Not everyone decides to use linoleum for a warm floor, believing that from heating the coating will lose its performance, become soft or crack. Many fear that when heated, linoleum will release harmful substances and create an unpleasant odor. All this is partly true, but does not apply to all types of coverage. A good material tolerates heat perfectly, without completely changing its physical and aesthetic characteristics. However, when purchasing products, you should study its compatibility with high temperatures. Even the highest quality products are designed for a certain range. Before choosing a product, you need to carefully read its certificate.

Advantages and disadvantages of linoleum

Coating has a long history of application. Manufacturers are constantly working to improve its composition and appearance.

Material advantages:

- Affordable cost. This is the first thing owners of a limited budget for repairs pay attention to. The price per square meter of coating is several times lower than ceramic tiles, solid wood, laminate and parquet.

- Variety in composition and arrangement. The buyer can purchase products of the cold type without a substrate and warm coatings lined with felt or foamed polymer.

- A wide selection of colors and patterns. Depending on the purpose of the room for its decoration, rolls with a plain or colored surface, with a smooth or embossed pattern are purchased.

- Flexibility. Due to this quality, linoleum can be used for sagging plates and curved sections.

- Easy styling. The material is easily cut to the desired size with improvised tools. You can lay the blank on the floor in a matter of hours.

- Ease of maintenance. The surface is cleaned with household detergents without any special effort.

- Durability. Linoleum is resistant to damp, it does not start mold and fungus, insects and rodents avoid it.

Cons of coverage:

- The need for preliminary preparation of the foundation. Lay strips can only be on flat surfaces without cracks, tangible depressions and protrusions. If they are not repaired, defects will appear on the coating.

- Insufficient strength. The material is easy to cut and pierced with sharp objects. Moving furniture over it is contraindicated.This feature is especially acute in the kitchen, where linoleum quickly becomes unusable from contact with dishes and cutlery.

- Destruction by ultraviolet radiation. If you lay the cover in the loggia, after a year it will fade and lose elasticity.

- Size instability. As the temperature rises, the coating expands, and when it decreases, it contracts. To prevent deformation, linoleum should be put on glue.

Linoleum continues to be popular, including as a decoration for warm substrates. To make the right choice, you should familiarize yourself with the types and features of heating systems and the rules for their installation.

Types of underfloor heating

Choosing the type of underfloor heating for finishing with linoleum, it is necessary to take into account a number of factors, each of which has its own significance. You should start with the architecture of the building and the ability to use a certain type of system in it. Then you should evaluate the feature of each room, their operating conditions individually and the entire building as a whole. Last but not least, pay attention to the price. If your budget is tight or tight, deadlines can be considered a temporary solution. In some cases, it helps to effectively get out of a difficult situation.

Water

The water heating system is used if you have your own boiler or a heated towel rail working year-round. Connecting the circuit to the central system is prohibited. The reasons for the limitations are the heavy weight of the pipeline walled up in the cement screed and the risk of leaks with serious consequences.

A warm water floor is a combination of such parts:

- Handsets. To create contours, products from flexible plastic, polypropylene or metal sections are used.

- Mixer. Designed to reduce the temperature of the water entering the tube to the optimum value.

- Collector. The product is responsible for the uniform distribution of fluid pressure when several circuits are installed in a large room.

The tubes are laid in molds, after which they are poured with concrete. Linoleum should be chosen for a warm water floor without a substrate or with a base made of foamed polymer. It is advisable to use models from natural components or PVC. Materials of this type conduct heat well, while maintaining their performance. Since the tubes have a large diameter, the total floor rise after installation will be up to 10 cm.

Electric

Products of this type are heating wires in heat-resistant insulation. Depending on the variety, they consume 100-250 W / m².

According to technical performance, they are divided into the following categories:

- Cables. They have a diameter of 8-15 mm, are sold in bays up to 100 m long. It is laid on a rigid base in the shape of a snake in compliance with the permissible bending radius. When choosing an electric underfloor heating under linoleum, you need to remember that after pouring the screed, the level will rise by at least 50 mm.

- Mats The products are thin heating wires fused into a strong polymer mesh. Products are strong and flexible, they can be laid on uneven and curved surfaces. It is preferable to lay the mats under ceramic tiles, since with a small thickness, 2-3 mm of the solution used in this process is enough. Another option is to cover the elements with linoleum with a soft heat-resistant substrate and a hard top layer.

After laying the heating elements, it is necessary to install a thermostat. This device is necessary to adjust the temperature and prevent it from rising to critical values.

Infrared

The tape infrared element consists of copper strips connected in parallel with graphite coated.Heat waves pass through any materials, including insulating linings. Thanks to this, you can use linoleum with a warm substrate, which creates an additional barrier from the cold. The undoubted advantage of IR film is the lack of the need for a cement screed. The coating can be laid directly on the heating elements fixed on the base. To prevent emergencies, an automatic temperature controller is installed.

Surface preparation

Regardless of which type of underfloor heating is chosen, for its installation it is necessary to prepare a reliable foundation that meets the safety requirements.

Concrete base is processed in the following sequence:

- Removing old finishes and remaining construction debris. Dismantling communications.

- Checking the condition of the surface. If there are gaps or openings, they must be repaired. Protruding fragments are grinded or chopped. If the slab is very sagging, it should be leveled with a light gypsum mortar.

- Primer deep penetration treatment. To achieve a better effect, you need to do this twice.

- Drawing a waterproofing layer. At the choice of the master, film or coating materials are used.

- Laying insulation. Depending on the characteristics of the premises, polystyrene, penofol or polystyrene are used.

- Covering the material with insulating material (roofing material, polyethylene).

In conclusion, the manufacture of a rigid base. Fiber cement boards with locks are used or screed is poured.

A wooden floor is prepared according to the following procedure:

- Removing the finish. If you plan to reuse it, you need to do this carefully and carefully.

- Examination of wood for rot, fungus and mechanical damage. Carrying out repairs in the required amount.

- Floor treatment with antiseptic and flame retardant. Application of liquid impregnation.

- Arrangement of waterproofing using strips of waterproof material.

- Laying and securing the membrane with staples to remove moisture.

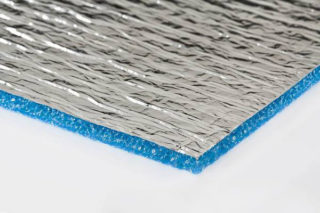

- Placement of insulation. For wood, it is better to use perforated penofol on aluminum foil.

Work should be carried out on well-dried wood. Otherwise, when dried, it will lead, which will cause deformation and destruction of the laid materials.

Installation procedure

For each type of underfloor heating, its own installation technology is used. It is carried out on the basis of a draft and calculations.

Water pipes are laid so that for one circuit there are no joints that cause leaks. The best option for fastening are foam blocks with grooves for the highway. Products are glued to the floor in accordance with the project. After this, the tubes are laid in the recesses, and their ends are connected to the collector.

It is advisable to fasten the heating cables to a metal mesh fixed to the carrier plate. The advantage of this solution is that the grid will serve as a frame for the future screed, adding strength to it.

Mats are fixed with glue or construction tape. So that the plane does not budge, it is advisable to impregnate it with a liquid mortar. After this, you can make a screed or lay linoleum.

The IR film is glued to the base with tape. Metal fasteners are not used, as there is a risk of breaking the electrical circuit.

The system is checked for operability, after which linoleum is laid.

Possible problems

Troubles associated with the installation of linoleum underfloor heating can occur immediately after repair or during operation. The most common problem is the softening of the material when heated.Often the surface goes in waves, there are often cases when the coating is compressed so that it comes out from under the baseboards. When choosing an inexpensive material, an unpleasant odor appears due to the release of phenol. The reasons for such phenomena lie in the wrong choice of linoleum and the absence of a temperature regulator, which leads to overheating of the finish and loss of its working qualities.