High-quality insulation of joints in panel buildings is impossible without mastic, which is used to fill joints between structural elements. It is used to seal and to reduce the costs of air conditioning and heating. Before working with this material, you should familiarize yourself with its technical characteristics and properties, study the available varieties, choose the appropriate option and follow the rules of the application technology.

Technical specifications and properties

Mastic for sealing joints in prefabricated houses has a high degree of adhesion or adhesion to the base, which must be completely cleaned. This material is resistant to environmental influences, including high humidity, high and low temperatures. High-quality mastic for external use from well-known manufacturers has a maximum service life and reliably protects seams for many years. In addition to a long period of operation, modern mastics do not cause problems during application, the entire process requires minimal physical effort.

This is an economical and affordable material, most sealing compounds for thermal insulation can be purchased at an affordable cost. Due to the low consumption per linear meter, one package can be used repeatedly as needed. Most sealing materials are available for use year-round, including in the winter season. In this case, one must take into account the risk of erosion of the joints in the absence of high-quality drains for water in the house.

Varieties of mastic

Mastic for interpanel seams of three types is presented on the market, each of the categories has its own characteristic features. The sealant may be one-component and may not require preparation for application or two-component and may require mixing several components before work.

Butyl rubber

Butyl rubber mastic can be used in winter at temperatures up to -20 degrees due to the presence of organic solvents. In more severe frosts, this type of sealant should not be used for work. The material is used only for sealing external joints, since after hardening such mastic releases toxic substances. The service life of the material is not more than eight years.

The butyl rubber compound is fire hazard until fully seized. Up to this point, there should be no open sources of fire nearby. Specialists working with the team must wear protective clothing, gloves and goggles.

Polyurethane

Polyurethane insulation for joints and seams can be one- and two-component, the second option has a longer shelf life. Mastic of this type has a high degree of adhesion to various surfaces, including wood, logs and beams, as well as glass and metal. Sealant made of polyurethane is considered the highest quality, its main disadvantage is the high cost. At the same time, this mastic has ideal performance characteristics and has a maximum service life of up to fifteen years.

Acrylic

Acrylic mastics are not used for sealing joints and seams in prefabricated houses on the outside, since they do not withstand washing out with water. They are ideal for internal work, as they do not emit toxic substances, have a high level of adhesion and are completely fireproof.They are used to eliminate gaps from the inside in the walls of apartments, houses and office premises, acrylic sealants provide internal sealing and increase sound insulation.

- Polyurethane sealant

- Acrylic mastic for interior use

Mastic preparation

The technology of the preparatory phase depends on the type of sealant. If it is one-component, it can be applied without prior preparation. Two-component compositions must be pre-mixed in the indicated proportions and measurements taken when it comes to processing small sections of a panel house. After mixing, the mastic changes the consistency and begins to resemble rubber.

The transition of the sealing state to the working one is irreversible, therefore, the components and the size of the proportions should be accurately calculated in advance. The time intervals for the solidification of the composition are indicated on the sealant packaging or in the accompanying passport. These data need to be taken into account, especially if you need to close up the seams and strengthen the joints in large areas.

Sealant dyeing

The process of coloring or coloring mastic is a mandatory step and is carried out to give a complete look to a panel house. Butyl rubber type sealants that can be painted with any paint are best suited for this purpose. Polyurethane materials are more demanding on the effects of coloring agents. Information on the type of paint must be clarified with the manufacturer of the sealant upon application. If this is not possible, experts conduct test stains using several types of paints and varnishes.

Paint can only be completely hardened after the insulation of interpanel joints and seams. To choose a coating for sealant, you must take into account the instructions from among the recommended options. Otherwise, the paint may not fit, and installation work will not lead to the desired result.

Application technology

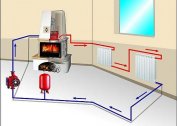

To seal and insulate the joints with mastic, it is necessary to observe the technology and rules for the use of sealant. Sealing joints in panel-type houses is primary and secondary - directly during the construction of a building and during repair work. In the primary procedure, a sealant is laid in the seams or treated with special materials, after which a layer of waterproofing is added. It is important to ensure that the components of the mastic remain resistant to precipitation and temperature extremes.

Reprocessing of joints in the house is permissible no later than seven years after its construction. The life of any sealant is not more than fifteen years. The rules of secondary sealing directly depend on the condition of the joints, in the absence of visible defects, only the outer layer is replaced, if the joints are badly damaged, all old materials are removed and the joints are filled with new ones. To avoid possible problems, during installation, observe the basic rules:

- If the horizontal joints have defects, the joints are sealed with at least three rows vertically.

- In case of violation of the integrity of the vertical seam in the longitudinal facade, both vertical cracks and adjacent horizontal cracks need to be repaired.

- When carrying out restoration work from the end, one should not forget about the seams that need to be insulated between the longitudinal walls and panels in the end and front parts.

The mastic should have a plastic consistency, since the seams between the panels can change size due to shrinkage, creep of concrete, temperature changes or due to the effects of loads. Rigid material can provoke depressurization of joints and the need for additional work. It is necessary to lay the sealant in a layer that will be twice as thin as the joint.