Most often, insulation, performing the simultaneous functions of protection against noise, can be claimed in the repair of old apartment buildings with ceilings from precast or monolithic reinforced concrete slabs. Among the most popular building materials for these purposes is the usual insulation polystyrene foam or its extruded version. This is due to its low cost and ease of installation.

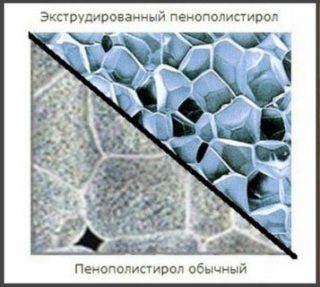

Extruded polystyrene foam and its difference from conventional

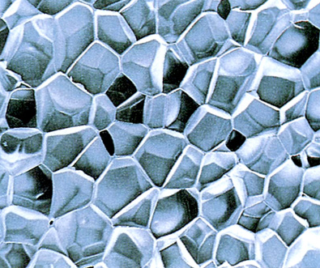

Conventional polystyrene foam is obtained in closed forms from granules, which foam and compact when exposed to hot water vapor. Extruded polystyrene foam insulation in the form of plates is made by pressing through a mass of expanded polystyrene, calibrated by the width and height of the slit, obtained at high pressure, temperature, with the introduction of a foaming agent. Such a material has increased strength, uniform distribution of closed pores. The slab form of release allows the use of dense expanded polystyrene as a heater and sound insulation material in a variety of areas.

Material Specifications:

- density - 8 ... 45 kg / m3;

- compressive and bending strength - 0.25 ... 0.50 MPa;

- daily water absorption - 0.2% of the volume;

- coefficient of thermal conductivity - 0.028 ... 0.042 W / (moS);

- vapor permeability coefficient - not more than 0.05 mg / mchPa;

- combustibility group - G3;

- temperature range - from -50 to +75 ° C.

These figures are highly dependent on manufacturers. Among the most popular include Knauf, Ursa, Technonikol, etc.

Material Properties:

- possesses high moisture resistance;

- resistant to biological pollution;

- effective sound insulation - up to -35 dB;

- low cost;

- using flame retardants resistant to prolonged high-temperature fire exposure;

- neutral to weak chemical influences, including atmospheric;

- environmentally friendly and safe during normal use;

- period of use - from 50 years and above.

Extruded polystyrene foam is produced in the form of plates of 100-200 mm in width and 800-1400 mm in length. The thickness of the plates varies from 10 to 40 in increments of 10 millimeters.

Fields of application

Extruded polystyrene foam is used as a heat insulator and noise suppressor in many industries, but it has received the greatest distribution in the construction industry.

Building material and waterproofing

In the construction of buildings and structures, EPSs are used for various purposes. First of all, it is thermal insulation and noise protection. Extruded polystyrene insulation has extremely low water absorption and water permeability. If the humidity regime of the insulated room is not too aggressive, you can save on waterproofing as a separate type of work.

Heat insulating element

Expanded polystyrene is used in the form of plates that are convenient to install on vertical and horizontal surfaces. For fixing use special adhesives, as well as dowels with screws, wire, tape made of metal and plastic. Sealing the joints is carried out with silicone mastics, retaining rubber-like properties after setting. This is necessary so that, over time, shrinkage gaps and crevices do not appear in the seams that impair the heat and noise insulation properties.Another option is the use of panels with a special configuration - with locks (spikes and cutouts) at the ends.

For the construction of building envelopes

In the construction of walls and floors, extruded polystyrene foam is used in the following options:

- direct installation “butt” on work surfaces inside or outside (facades or insulated attics);

- installation in cells of wooden or metal elements of frames for sheathing with sheet trim;

- in the form of pre-made sandwich panels, where it is clamped between two sheets of finish based on wood, plastic or profiled metal for use in the construction of frame houses and other lightweight prefabricated buildings.

Sometimes on sale you can find stamped siding panels with extruded polystyrene foam sprayed onto the back. They combine the insulation of the facade with decorative finishes.

As a universal insulation

EPSS is used as the most inexpensive universal insulation for thermal protection:

- machines and mechanisms (including construction);

- kilns;

- production facilities and workshops with heavy (high temperature) operation;

- boiler rooms;

- boiler rooms;

- warm garages;

- facilities for keeping pets;

- freestanding, as well as built-in baths, saunas and swimming pools;

- chimneys and bends;

Also, the material is used in permafrost in the construction of light buildings or roads and railways to isolate frozen soil from thawing, resulting in unforeseen subsidence.

As glass

Polystyrene panels and panels of small thickness transmit up to 60% of the light incident on them. This property is sometimes used to reduce heat loss and ambient lighting with diffused light, where the use of transparent glasses is impractical. It can be:

- locker rooms;

- showers and toilet cabins;

- refrigerators;

- warehouses

- places for cutting carcasses.

Such light sources additionally combine the properties of thermal protection and sound insulation.

Floor insulation options

Foam plate insulation for floor insulation can be used in several versions. If the floor is wooden, the empty space between the beams, lags and the floor covering is filled with polystyrene plates using layers and trimming them to the desired height.

When repairing old houses under the floors, you can find a backfill of ash and slag or expanded clay, which must first be carefully removed and the resulting voids cleaned from dust with a vacuum cleaner and wet cleaning. Replacement with expanded polystyrene will significantly improve the thermal protection and sound insulation of such floors.

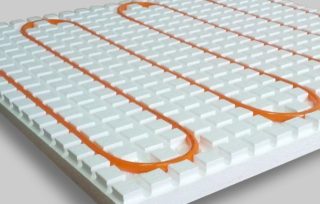

Expanded polystyrene for a warm floor is rarely used. More often for these purposes, use plates of mineral fiber stone wool. Material for underfloor heating should be of increased density and temperature resistance.

Screed insulation

When using polystyrene foam on the floor under the screed, if the floor is reinforced concrete, it is better to level the concrete surface with a cement-sand or water-resistant filler composition up to 1 ... 2 cm thick. In the case of using wooden girders or logs for a board, chipboard, plywood floor, the polystyrene foam should fill the space between them to the desired height.

If there are no lags, expanded polystyrene under the screed in the form of plates or panels is installed “butt”, foamed polyurethane (in cans) or adhesives and mastics based on vinyl acetate, acrylates, silicone can be used for fastening.A protective leveling screed made of cement-sand mortar or expanded clay concrete with a thickness of at least 5 cm is arranged on top of the plates.

To improve the waterproofing and vapor permeability between the solution, it is recommended to lay one or two layers of rolled polyethylene film on the polystyrene foam extruded under the screed. As a topcoat for such a floor, linoleum, laminate, parquet, porcelain stoneware or ordinary tile, self-leveling self-leveling floor can be used.

Ground laying

When laying thermal insulation directly on the ground, which often happens when warming the floors of the first floors of old basement high-rise buildings, the base should be aligned as accurately as possible in the horizontal plane. If necessary, you need to apply quarry or river dry sand.

Before laying, it is better to use rolled geotextiles, which create a membrane that protects against the effects of natural moisture in the soil on overlying wooden or concrete structures. At the end of this stage, the same algorithm should be continued as in insulation for screed.

Any, even unskilled craftsman can independently cope with the work of insulation with the help of extruded polystyrene foam. However, to select a material, explain the technology and methods of its installation, receive answers to other questions, it is better to use the advice of a specialist who has experience in thermal insulation. Often an invitation from a third-party wizard helps save time and money in the event of a marriage and the need for alteration.