On sale a lot of polymer sheet insulation materials for construction work. Each type of polystyrene is designed for specific thermal insulation purposes. An improperly selected product can bring undesirable consequences after its installation: a weak effect of insulation, dampness on the walls and even the destruction of load-bearing structures. To avoid problems, it is necessary to study the characteristics of the product and know the necessary density of extruded polystyrene foam.

What is the material?

Among all expanded polystyrene, extrusion is the most durable. This polymer is produced in the form of sheets of a certain size. The structure itself is obtained by foaming polystyrene, while it goes through the stage of heating in the extruder to a state of melting. Then it is squeezed into a specific shape and cut off after cooling.

The high strength of such a heat insulator is due to its fine-mesh structure obtained at the time of sintering. The pores inside the polymer have a closed round shape, due to which the extrusion plastic (EPS) does not allow steam and moisture to pass through it.

Class Characteristics

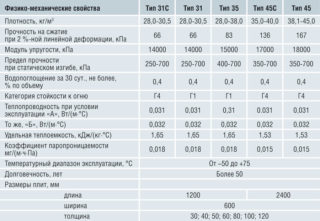

EPSP of different types has different characteristics. All known extruded products can be divided into three large groups:

- Class 30. The product is used for thermal insulation of structures that are not subjected to mechanical stress: underground communications, vertical parts of foundations, roofing planes.

- Class 35. The product can be used both outdoors and indoors when insulating walls, ceilings and floors. Plates differ in the content in the structure of flame retardants for better fire resistance.

- Class 45. Extrusion plastics of this category are the most durable in terms of compression applied to them. They can withstand loads of up to 0.5 MPa. Such a product was mainly used in the construction industry for the construction of routes, strips for take-off of air transport, and for the insulation of monolithic slabs.

Characteristics of Penoplex available in the domestic market:

- The sheets have a thickness of 15.12, 10, 8, 6, 5, 4, 3 and 2 cm.

- Canvas size: 120x60 cm and 240x60 cm.

- The thermal conductivity index is 0.032-0.030 W / m * С.

- The compressive strength is 0.5-0.2 MPa.

- Moisture absorption is about 0.40%.

- Flammability with the G4 index.

Penoplex is a domestic product; carrot color is available. The polymer is intended for industrial use and for domestic purposes.

Technoplex - extruded polystyrene foam, which has a smaller number of varieties in terms of web thickness, is represented by 10, 5, 4 and 3 centimeters. The sheet size standards for this product are: 118x58 cm and 120x60 cm. The thermal insulation characteristics of the material are worse by about 0.002 W / m * C than Penoplex, but the moisture absorption is 0.2% less. Due to the presence of graphite inclusions in the polymer structure, the heat insulator has increased strength. It can be used under heavy building structures.

Extruded URSA plastic is produced by an imported manufacturer. The company makes polymer heaters with a standard sheet size of 125x60 cm and a thickness of 10 to 3 cm. The product is similar in strength and combustibility to Technoplex.

Strengths and weaknesses of extruded polystyrene foam

Among the advantages of XPS can be distinguished excellent thermal insulation characteristics, strength, moisture resistance and lightness of the sheets.

It is easy and convenient to work with the material; powerful lifting equipment is not required in order to supply insulation to the upper floors of the construction site.

Of the disadvantages of the product in the first place is combustibility. At an ambient temperature of more than 75 degrees Celsius, harmful fumes begin to stand out from the structure. Also, you can not leave the heat insulator in direct sunlight, which destroy it. Rodents can settle in the thickness.

Comparison with foam

Compared to extruded insulation, polystyrene (PS) has a completely different manufacturing technology, which ultimately introduces differences in these two products:

- In terms of strength, the foam of any brand is very fragile and can withstand a maximum pressure of only 0.2 MPa.

- The structure consists of individual spheres of different sizes, bonded by sintering in a press.

- The cells have micro-slots between them, which contributes to the partial absorption of water by the foam.

PS is never used to insulate structures that can be subjected to any mechanical stress. The color of the foam is always snowy white.

If we compare the EPS with ordinary plastic, the advantage of the latter can be considered cheaper manufacturing technology and vapor permeability, which is also higher, so that the insulated buildings have the possibility of gas exchange with the environment. In all other respects, the material is inferior to extrusion insulation.

Product Application

Extruded insulation is used mainly in the construction industry for insulation of various objects and communications. As a heat insulator, XPS is suitable for arranging:

- the walls of the building outside and inside the rooms, except for rooms where the temperature exceeds 60 degrees Celsius;

- foundations, basement floors and monolithic slabs of various designs, both from the ends and under them;

- warm blind areas around the house;

- heat mains and heating mains;

- any underground facilities and communications.

In addition to all of the above, EPSs can be laid in the base of heated roads and tracks. There is also such a thing as a sandwich panel, the inner space of which is filled with foamy polymer.

Home-made

It is impossible to get XPS at home; this requires expensive equipment - an extruder and a production line. You can make ordinary foamed plastic from polystyrene granules. At the same time, one should not pay attention to the independent production of plates - it will be unprofitable. Such an idea is suitable for getting bizarre forms in order to engage in Hand Made. The technological process is as follows:

- Granules are poured onto the fifth part of the bucket and the steam generator hose is directed into them.

- The raw materials are poured over steam and at the same time mixed until it grows in size.

- Spread the balls in a pre-cooked mold and continue to warm in it with a hot stream until sintering.

At the end of the process, the mass is allowed to cool. The form is opened or broken to get the finished product. The more elegant the item, the smaller the initial balls should be in diameter.

Insulator installation

Fixing sheets of extruded insulation to horizontal surfaces is carried out using cement-polymer-based glue. To withstand wind and other loads, it is imperative to strengthen the fastening of each plate with plastic dowels with umbrella-shaped hats.

If EPPS is laid on horizontal concrete substrates, laying on bitumen mastic is the best way.

It is necessary to carefully study the characteristics of bitumen glue before use. Not all brands of this substance are suitable for the polymers in question. Incorrect selection may result in dissolution of the insulation surface.

All EPPS sheets have smooth surfaces, as a result of which they are poorly glued to concrete and plastered planes located vertically. It does not matter which side of the slab will be internal or external - they are identical in structure. It is recommended for better adhesion with the supporting structure to process one of the sides of the foam with a metal brush in order to achieve roughness.

During the installation of insulation, one of the operations is to cut the parts to size in those places where the dimensions of the product go beyond the enclosed structure. To cut the XPS, just use a construction knife with interchangeable blades. It is convenient to carry out cutting on a flat surface such as chipboard or OSB.

Manufacturers of popular products

Expanded polystyrene has a lot of advantages, so many foreign and domestic manufacturers have included this building insulation in their product line.

Thermit - Krasnoyarsk plant for the production of effective thermal insulation. Makes XPS for various warming tasks. The products are made in accordance with GOST 32310-2012 and have earned many medals at exhibitions.

Comfort is XPS, which is one of the brands of Penoplex. It comes in different thicknesses with sheet sizes of 585x1185 mm. The package comes packed with a special film that protects against UV radiation.