Heat-insulating paint for walls is actively used, if the use of paints is provided for at the cladding or finishing stage. Thermal insulating paint has low thermal conductivity, so in the future it will be possible to save on space heating with the advent of cold weather. Thanks to the innovative composition, a reliable protective coating is formed on the wall, which extends the life of the surface.

Scope of heat-protective paint

Thermal insulation paint is mainly used for decorating basements, roofs and the facade of a house. It is often used by garage owners. For additional thermal protection, the composition is applied to the ceilings.

In construction, warm paint is used to process the following surfaces:

- roofing structures;

- frames of prefabricated structures;

- loggias / balconies;

- floor floors;

- walls that are located close to the stairwells;

- insulated facades.

The building product has found wide application in the field of agriculture and utilities, in industry.

Benefits of using

Thermal insulation paint for walls and pipes has a fairly extensive list of advantages, which is due to the popularity of the product in the construction market.

Main advantages:

- the composition does not burden the treated surfaces;

- the ability to use a liquid composition even in the most inaccessible places;

- the processed surface can be painted in any color;

- simplicity, convenience and high speed of applying the composition - for spraying use a spray gun, brush and roller;

- possesses high tenacity with other materials, including metal, plastic and concrete;

- condensation does not collect on the treated surface;

- high resistance to saline solutions, alkali, chemicals, exposure to ultraviolet radiation;

- the composition of the paint does not burn and does not decompose into components;

- with strict adherence to the attached instructions for use, you can perform all the work yourself, without resorting to hiring specialists.

One of the main advantages is that the paint composition is evenly distributed over the surface, which allows you to insulate relief surfaces.

Functional features of thermal insulation coating

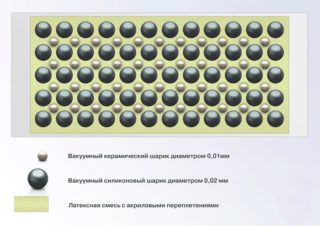

The composition of the thermally insulating paint material includes the following ingredients:

- water;

- fillers;

- acrylates;

- additives.

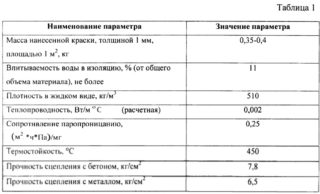

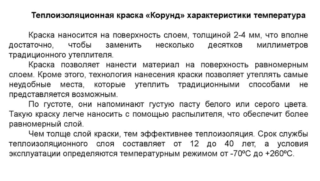

Perlite, fiberglass, foamglass and ceramic granules act as additives. Protective paints consistency reminiscent of a thick paste of white or gray color. On the surface of the structures they must be applied with a thin layer, approximately 2-4 mm. The thermal insulation properties of the coloring composition are determined by its thickness. The more layers will be applied, the higher the protective properties. The operational life is approximately 10-50 years.

Varieties of insulation paints

Heat-insulating coloring compounds are divided into several varieties according to the composition and objects of use.

Heat-insulating coloring compounds are divided into several varieties according to the composition and objects of use.

By composition:

- on an acrylic basis;

- water based.

According to the object of use:

- facade thermal insulation composition - is used to carry out only external works, it is characterized by moisture resistance and heat resistance;

- heat-insulating paint for pipes - used for painting air conditioning and ventilation systems, water supply and gas pipelines;

- thermal insulation compounds for walls - suitable for the treatment of ceilings and floors, internal and external walls.

Choosing the best option is usually not difficult.

Tips for choosing paint thermal insulation

Before you buy a composition that costs a lot of money, you need to familiarize yourself with the basic rules and recommendations of the purchase:

- determine the functional load;

- if the composition is necessary for the treatment of walls, ceilings and pipes indoors, the composition should not contain toxic and harmful substances for the human body and animals;

- calculate the required amount of product;

- for the facade, it is better to give preference to a composition with maximum vapor permeability and minimal water resistance;

- choose the best from trusted manufacturers, having previously familiarized yourself with the features, advantages and disadvantages;

- compounds intended for painting pipes should have maximum heat resistance.

To ensure stable and reliable thermal insulation, it is necessary to apply the substance on the surface to be painted in several layers.

Quantity calculation

Before buying a thermal insulation compound, you need to calculate the approximate amount of paint consumed. When calculating it is important to consider the following factors:

- method of applying paint: spray, roller or brush;

- variety of base coat: brick, metal, wood, foam concrete, expanded clay concrete, concrete;

- the painted surface is flat or embossed;

- weather;

- the presence or absence of pores;

- if the pipeline is painted, its diameter is taken into account;

- surface area;

- paint coat thickness.

Consumption may be exceeded if you have to work with an uneven and / or porous surface. For wood and concrete, the increase in consumption is about 10%, for metal no more than 6%.

If during the work the weather is sunny and calm, the consumption of paints and varnishes is reduced by 2-3%. The average consumption of the composition is 1 liter per 1 sq.m. subject to the application of a millimeter layer. For some surfaces, a thicker coat of paint is recommended. For example, for wood - 2 mm, foam concrete - 2.5 mm, and for concrete - 1.5 mm.

Domestic manufacturers

If before you did not have to deal with the choice of heat-insulating paint, it is better to give preference to trusted and well-known manufacturers.

If before you did not have to deal with the choice of heat-insulating paint, it is better to give preference to trusted and well-known manufacturers.

Corundum

Liquid heat insulators produced by the company are used for processing the following types of surfaces:

- pipelines;

- metal tanks;

- railway cars, passenger planes and motor vehicles;

- rooms with high humidity;

- chimneys;

- boiler rooms;

- surfaces inside residential and office buildings;

- boiler rooms;

- facade of buildings.

The company produces several varieties of coatings, depending on the scope of use.

Thermalcom

Manufacturer Termalkom produces paint coatings called Astratek. Polymer based formulations are made. The product is extremely in demand, because it combines reasonable cost with high performance.

Liquid thermal insulation is widely used in the field of housing and communal services, various industries and construction. There are six types of thermal paints from this manufacturer on the market.

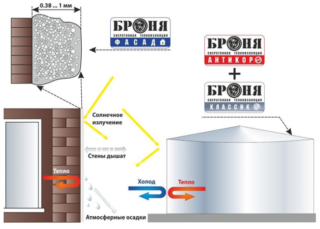

GC VIRTS Bronya

Construction products manufactured by Bronya are widely used in industry and construction. The company offers each potential buyer the best conditions in the ratio of price / quality.

Construction products manufactured by Bronya are widely used in industry and construction. The company offers each potential buyer the best conditions in the ratio of price / quality.

Previously, products were mainly used for surface treatment of water supply systems and gas networks.Today the range of heat insulators is actively replenished and is divided into 3 large groups:

- special;

- basic;

- budgetary.

It is recommended to purchase materials from official representatives or in large construction stores, where they can provide all quality certificates and a guarantee.