Despite the abundance of modern models of heaters operating on cheap types of energy, traditional wood-burning stoves are still very popular. Among them stands out a design called “Professor Butakov’s stove”. It can be used for heating the premises of country houses, as well as greenhouses, warehouses and garages.

History of creation

The first sample of such a furnace was made in 2002 in the north of the country, in the Novosibirsk region. Only two months after that, the necessary certificates were received, and by 2004 a patent for the invention was issued. Its developer is a specialist in the field of heat engineering E. Yu. Zubkevich, who named the stove in honor of his relative, professor S.E. Butakova.

A year later, the inventor entered into an agreement with the company Thermofor, which mastered the production and production. For a number of reasons, in 2008, cooperation with it was suspended and the patent holder remained in no business. To date, the production of these furnaces has been established on an industrial scale.

The device and principle of operation

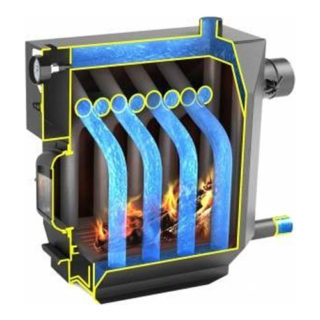

Butakov’s designs are based on a welded body with pipe channels built into it, inside which convection processes occur. In this case, cold air through the pipe system enters, and then heats up in the body and already exits hot through the upper outlet. Then it spreads throughout the heated room, bringing the temperature in it to a comfortable level. Such pipes can be located on the front and rear sides of the structure.

Firewood is used as fuel in these devices. In addition, they can be heated with special briquettes called pellets. The upper plane of the body may be used for cooking or for heating liquid foods and water. It itself is painted with a paint based on organosilicon elements and is coated with heat-resistant oils, slightly charring when heated. Therefore, the first firebox is necessarily organized outside the premises, its duration is at least 1-2 hours. In all subsequent ignitions, the burnt smell will no longer spread.

The design is based on the principle of convection - the property of warm air rises upward. Oven products of the Buleryan type function in a similar way, the difference of which lies in the absence of a grate for them. This famous design was taken as a basis by Yu. Zubkevich in the development of his invention.

The grate of cast iron, which is equipped with new products, reliably protects the bottom of the furnace from burnout, since it takes on the bulk of the heat. When this structural element burns out, it is easily replaced by a new one. In addition, the presence of a grate ensures an even distribution of fire throughout the firebox, as well as the ability to adjust the air supply. With its increase, it is possible to accelerate the entire process of heating the room. Through the cast-iron grate, the combustion residues fall directly into the ash compartment, from where they are subsequently removed.

Cleaning the furnace is possible directly during operation, which allows the use of fuel with a high content of soot. In addition, intense combustion speeds up the process of its disposal. To control this procedure, the ash compartment is equipped with a valve that allows you to adjust the supply air dose.

Stoves of this class are used exclusively in smoldering mode and are not intended for continuous operation at temperatures above + 350 ° C.

Classic lineup

Butakov’s stove has a well-thought-out design, suitable for almost any interior and setting. The product lineup includes the following items:

- High School Student and Student;

- Engineer and Associate Professor;

- Professor.

High school student

The model is characterized by the fact that its main purpose is cooking. A hob weighing 49 kg is provided in the upper part, which is absent in other models.

The chimney outlet is located in the same part of the housing, taking up little space in the room. In addition to the claimed advantages, this model also has disadvantages. One of them consists in the fact that condensate and soot get from the vertically arranged pipe back into the furnace. It is very inconvenient to clean such a chimney, because before that it has to be completely dismantled.

Product Features:

- The declared power is 5 kW with an efficiency of 85%.

- The permissible volume of a room that can be heated is 50-100 m³.

- The dimensions of the furnace body are 400x500x500 mm and weighs 34 kg.

- The volume of the furnace is 60 liters, and the diameter of the chimney pipe is 115 mm.

Student

The model belongs to the most common samples, optimally suitable for cottages and well-insulated mansions. Heating furnaces under this name are distinguished by a large pipe diameter and relatively thin walls, which can improve heat exchange with the external environment.

The chimney outlet mounted by means of a tee is located on the back of the housing. This design allows you to clean it without removing from the stove. To do this, simply remove the bottom of the tee, in which the bulk of the condensate and soot accumulate. In this part of the body there is a valve that allows you to adjust traction, as well as a special fitting designed to remove condensate and dirt.

Model Features:

- Power - 9 kW with an efficiency of 85%.

- The size of the room that can be heated is 150 m³.

- With a weight of 57 kg, the dimensions of the furnace are 370x545x650 mm.

- The volume of the furnace is 74 liters, and the diameter of the branch pipes is 120 mm.

Variants of the Student model differ only in cost: wood with a steel door, coal with a metal-based sash and with a cast-iron door equipped with glass.

Engineer

Professor Butakov’s stoves of the Engineer type are among the more powerful and popular models, ideal for private homes and work sites. Like a Student, the structure contains enlarged convective pipes with thin walls.

Her characteristics:

- The power declared by the manufacturer is 15 kW with an efficiency of 85%.

- The volume of heated spaces - 250 m³;

- The volume of the furnace is 120 liters.

The pipe diameter of this product is 120 mm.

Docent

Furnace Associate Professor - a further development of previous models, characterized by its capabilities and power. As a rule, it is used for heating mansions, cottages, as well as industrial and storage facilities.

Technical specifications:

- Power equivalent to electric - 25 kW.

- Efficiency - 85 percent.

- Permissible volume of heated spaces is 500 m³.

- The volume of the furnace is 250 liters.

The stove has a chimney of 150 mm.

Professor

The stoves of the Professor type are the most powerful units from the entire range of models presented. Their parameters:

- Maximum power - 40 kW.

- The size of the room that is heated with their help is 1000 m³.

- With a weight of 57 kg, its dimensions: 670x1110x1250 mm.

The average diameter of the Professor’s stove pipe is 200 mm. The cost of individual modifications reaches 32,000 rubles.

- Professor - heating area of 1000 square meters. m

- Associate Professor - heating area of 500 square meters. m

Safe installation of the stove and chimney

To install the chimney on the engineer Butakov’s stove, you will need to familiarize yourself with the installation instructions for it, which describe in detail all installation operations.There is also a diagram of the connection of pipes to the output manifolds of the unit. During their installation, special attention is paid to the issue of fire safety, which is primarily manifested in the selection of a suitable place.

Butakov’s boiler, as a rule, is installed directly on the floor of a residential or industrial building. It is placed on a flat surface, covered with a sheet of iron on top of a ten-millimeter asbestos flooring. On its base there are mounting holes, allowing, if necessary, to fix the housing on the floor. During installation, it is important to ensure that the furnace firebox and the housing are at least 380 mm from the walls and floor. If it is not possible to provide the required clearance, it is recommended to insulate the wall surfaces at a level of 25 cm above the top of the boiler. To do this, you can use one of the following methods:

- cover with a layer of reinforced heat-insulating plaster 25 mm thick;

- place on the protected surfaces a 10 mm piece of asbestos with a steel sheet on top.

To isolate the floor in front of the furnace door, it is necessary to lay a metal sheet of the required size.

It is also important to determine the exact place of installation of the chimney in the overlapping zone on the ceiling surface. After marking it, a square hole is made in the selected area, insulated with basalt wool on metal sheets. According to the drawings, the Butakov’s stove is connected to the finished chimney by means of a special tee, which ensures that the remaining combustion of firewood (soot) and condensate settles in it. Particular attention is paid to the quality of pipe joints, for which all joints of the gas exhaust system are sealed with heat-resistant sealant.