To eliminate heat leaks and create additional space, glazing and warming of the balcony is performed. Work can be done on the inside and front of the apartment. Before they begin, it is necessary to choose a method and heat-insulating materials.

The need for insulation and glazing of balconies

During the construction of houses, standard structures without thermal protection are created. High-quality thermal insulation of the loggia solves several problems:

- reduction of heat loss of the apartment;

- expansion of the area of residence;

- ensuring soundproofing of the room;

- creation of an additional working and leisure zone;

- maintaining normal temperature and humidity.

45% of the heat comes out through the old frames, so it is advisable to combine the insulation of the balcony with the repair.

Varieties of insulation

The balcony room and loggias are mostly not heated, therefore they are places through which heat flows. Access to cold air is possible even with quality glazing. To normalize the microclimate in the rooms, it is worthwhile to perform internal insulation. There are several work technologies. When choosing them, you need to consider:

- The purpose of the operation of the balcony. The storage area is insulated around the perimeter, the resting area is from the side of the room, the loggia-office, the library or the gym are through the windows over the entire surface.

- Financial opportunities. It is necessary to calculate what area the heater will occupy, to choose its type.

- Season. Thermal insulation solutions, foams and adhesives change their properties during thermal exposure.

- Material safety. Some types of expanded polystyrene or mineral wool secrete carcinogens.

In summer, work is faster and cheaper than in winter.

Cold way

Mounted aluminum profile without insulation materials, PVC windows with single-chamber double-glazed windows or single glasses. The design protects drafts, precipitation, dust from penetrating into the room, gives the loggia a beautiful view from the side of the facade. The method is called cold, since the high thermal conductivity of aluminum eliminates the support of positive temperature. Double-glazed windows cannot be placed on frames with an assembly width of 6 cm.

Cold glazing is justified for storage balconies.

Warm way

Allows you to replace aluminum profiles with high-quality heat-insulating structures. The warm method eliminates the presence of drafts, the formation of condensate, cost overruns when paying for heating and eliminates heat loss. Thinking about how to effectively insulate a balcony or a loggia with a cold type of glazing, it is worth considering several popular materials:

- Styrofoam. Differs in density, moisture resistance, low level of thermal conductivity.

- Styrofoam. Low-cost, but durable and easy to install thermal insulation.

- Basalt or mineral wool. Stacked into the frame, due to the random arrangement of the fibers does not allow cold air to pass through.

- PPU. The sprayed insulation, which is applied seamlessly and prevents the appearance of “cold bridges”.

- Penofol. A material with a polystyrene backing to retain heat and aluminum shielding, reflecting heat fluxes into the room.

All materials can be combined.

Frameless way

The panoramic view of the insulation is a window or a transparent wall through which you can inspect the territory. On the scale of the apartment it is executed as a loggia on which there is a double-glazed window from the ceiling to the floor or a balcony glazed in several planes. Frameless construction is implemented as follows:

- Connection of several sections of standard systems with a common frame.

- Front double-glazed windows with hermetic sealing of an assembly seam. They are placed on vertical crossbars with horizontal jumpers or continuous.

- Systems with a frame of monolithic, tape tempered glass. Sashes move like an accordion, sliding wardrobe doors or remain stationary.

Glazing a loggia in a frameless way is possible only for the purpose of protection from weather factors. High-quality thermal insulation in this case will not be.

The specifics of cold glazing

Cold glazing is carried out without insulation and represents aluminum profiles with double-glazed windows along the perimeter of the loggia. It is suitable if the space is not attached to the living room, but used as a place for storage and drying of linen. This option features:

- ease of preparation of the ceiling, walls and floor;

- installation of window structures on the balcony parapet or bars;

- type of construction - single glass with aluminum profiles;

- sliding sash opening system.

To implement cold glazing, two technologies are used - with and without removal. In the first case, the glass elements are carried out during the loggia period. You will need to fix the brackets 30-35 cm in length on the supporting bars, and a window sill is mounted between the balcony railing and the system. A double-glazed window is already placed on it.

The technology without removal involves the installation of double-glazed windows with profiles on the base of the loggia, which allows for additional amplification.

Features of warm glazing

It is possible to glaze and insulate the loggia at the same time with the help of a multi-chamber profile, glued wooden beam and a heat-insulating double-glazed window with two cameras. Profiles are made of the following materials:

- Metalloplastik. PVC structures with metal reinforcement inside are divided into 3, 4 or 6 chambers. The profile is leakproof, high energy-saving and noise-insulating properties.

- Wood. Frames are made of oak, larch or pine. Wood species look like glued together lamellas. The systems are maintainable, environmentally friendly, and well protect against heat leaks.

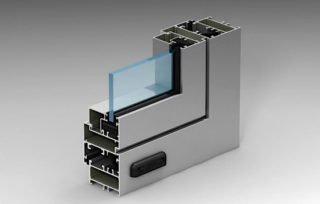

- Aluminum. Profiles consist of two elements and a polyamide dividing insert. The thermal bridge has a thickness of 2.5 m, so that the structure does not freeze, and the heat in the room is preserved.

Wood type frames are more expensive than plastic or aluminum.

The design of warm glass

Double-glazed windows are designed to prevent heat leakage as much as possible. The standard warm system includes:

- Glass. External elements 6 mm thick prevent exposure to external noise. The standard thickness of the inner sheets is 4 mm.

- Cameras. Three-chamber options are installed on fittings with reinforcement, single-chamber under warm glazing are available with a special energy-efficient coating. Optimal for installation will be a two-chamber type of double-glazed windows.

- Distance frame. An element with a size of 16 mm reduces noise absorption, eliminates heat leakage.

- Filling a double-glazed window. To save heat, dried air or inert gas (krypton, argon) is used.

The opening of the flaps is carried out using a rotary, folding or swing-folding mechanism.

Frameless Features

The frameless method is Finnish technology, which provides glazing without jumpers, partitions and frames.The design looks light and airy, suitable for a loggia terrace or a large balcony.

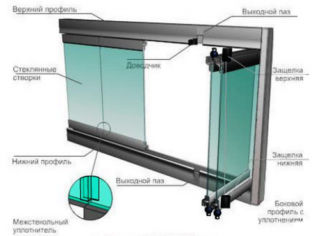

The panoramic type of glazing includes the following elements:

- glass 6-12 mm thick with polished edges;

- profiles - upper and lower, for which the main load is applied; for movement and rotation, the glass is equipped with output grooves;

- multi-section closer - sets the direction of a double-glazed window in a niche;

- lateral type of profiles - seal the junction points and balance the load;

- latches - are located above and below, are necessary for fixing the wings;

- glass profile - needed for fixing glass with glue and rivets, equipped with a pair of bearings;

- roller system - suspension or thrust mechanism holds the profile;

- drain cornice - it is upper and lower, prevents the penetration of sediment into the structure.

Frameless systems are mounted on a perfectly even parapet.

Pros and cons of warming

Cold

The advantages of the cold method include:

- minimum expenses for arrangement;

- beautiful appearance from the outside;

- preservation of the useful area of the loggia;

- the possibility of installation in apartments of complex configuration;

- ease of installation;

- low weight of the system in the assembly;

- lack of corrosion of an aluminum shape;

- fire resistance, reliability and durability of the system;

- possibility of installation in an old housing stock.

Cons of aluminum cold insulation - the impossibility of living in the winter, minimal tightness and freezing of the profile in the winter.

Warm

The strengths of the warm method are:

- good thermal insulation;

- noise protection;

- maintaining the quality of decoration;

- obtaining an additional room - an office, bedroom, dining room, relaxation area;

- resistance to wind loads and temperature fluctuations;

- reliability and structural strength.

Among the disadvantages of the technology are the financial costs of arranging (3 times more expensive than cold), reducing the useful area of the apartment, the need to arrange lighting and the need to strengthen the bearing plates due to the massiveness of the frames.

Frameless

Among the advantages of the frameless method are:

- light and airy design;

- full overview of the street or the natural panorama;

- fast glazing of large areas due to leaf lengths up to 12 m;

- maximum degree of illumination of the room;

- reliability of fasteners;

- ease of opening the wings;

- lack of injuries due to blunt and rounded edges of glasses;

- creating a barrier to dust, wind, precipitation, extraneous noise.

The disadvantages of the panoramic method are the impossibility of using energy-saving two-chamber double-glazed windows, the risks of breaking glass of standard thickness on the windy side of the house, small noise isolation (10-15 dB), compliance with the parallel ceiling of the balcony and the upper part of the parapet.

The procedure for warming the balcony with your own hands

There are several ways to insulate a cold-glazed balcony without replacing the glazing. It is allowed to insulate all structures without glass - walls, floor and ceiling, but the room will be non-residential. If the space is connected to the living area, it will be necessary to coordinate the redevelopment documents. Installing a warm floor will help to make a separate room if it is not connected to the bedroom or living room.

Do-it-yourself work is done as follows:

- Material selection. High-quality insulation of a non-residential balcony with a cold glazing system can be done using extruded polystyrene foam or polystyrene. Sheet thermal insulation is easily cut.

- Sealing cold bridges. All cracks must be treated with polyurethane sealants or mastic. The compositions are applied with a special gun or a complete nozzle.

- Alignment of the floor surface and walls.

- Arrangement of waterproofing coating with roofing material. The sheets are overlapped and heated by a burner along the seam. You can use sprayed or coated materials.

- Installation of the frame under the insulation. Wooden slats are fixed with screws on the ceiling or floor. Dimensions of the design are selected according to the size of the insulation.

- Cutting polystyrene foam. Sheets are cut to the size of the cells with a hacksaw or clerical knife.

- Laying plates. Special glue is used, applied with a spatula at a distance of 5 cm from the edge or dowels, mushrooms in the amount of 10 pieces per 1 m2.

- Sealing joints with foam. The tool is applied from a gun. After drying, the excess is trimmed.

- Installation of foil foamed polyethylene over the base layer. Sheets are laid end-to-end on polyurethane adhesive and glued with metal tape over the seam.

- Arrangement of the substrate for the finish. GKL or plastic is fixed on the dowels, but pre-glued to the insulation.

Use moisture-proof drywall for cladding - it eliminates the risks of mold.

To create a full-fledged living room or resting place from the balcony, it is advisable to choose the right technology. In order not to overpay for the replacement of double-glazed windows, it is recommended to lay insulating materials. If there is a desire to change the glazing, work can be combined with a major overhaul.