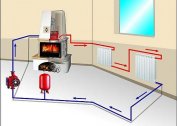

Autonomous heating is installed in many apartments and most private houses with their own water supply. This system is not designed for eternal work without maintenance and preventive measures. The circulating water does not differ in perfect purity. In the process of heating in the range of 45-75 degrees, a calcareous deposit forms in the pipes, soot collects from the outside. This negatively affects the efficiency of the equipment, leading to many undesirable phenomena. To prevent this, the boiler heat exchanger is cleaned. Perform this procedure better with your own hands, as the services of the master will cost a round sum. Tubing should be cleaned regularly as they become dirty.

The need for cleaning

High-quality washing of the heat exchanger of the gas boiler is the key to its long and trouble-free operation throughout the entire heating season. Faced with the need to turn off heat and emergency repairs during this period is not the best prospect that a property owner wants to face.

If the heat exchangers are not cleaned within the time recommended by the manufacturer, the following problems are likely to occur:

- Overheating equipment. This is due to the low speed of the water, which receives more energy than is required by the instructions.

- Gap contour. It occurs due to the conversion of liquid into steam when stationary due to clogged channels.

- Breakdown of the circulation pump. The unit overheats, since its power does not find a way out due to the inability to freely drive water.

- Increased noise. It occurs due to the swirling of the liquid and the formation of air bubbles, when the process of boiling in the tubes begins.

- Increase in gas consumption. To heat the room to the desired temperature, it is required to spend 1.5-2 times more energy.

- Decreased performance. It occurs due to soot accumulated on the tubes, which acts as a heat insulator. As a result, a double-circuit boiler delivers water 10-15 degrees colder than the specified parameters.

Timely flushing of heat exchangers will help to avoid such complications. If they did arise, you must immediately stop the system, drain the water from it and clean the internal circuits.

Heat exchanger flushing frequency

The frequency of cleaning the heat exchangers is specified in the operating instructions that apply to the product. Most manufacturers recommend doing this every 2 years. However, if water saturated with lime is used, a thick layer of plaque can boil in one heating season, even if the boiler has a stainless circuit. When a filtration system is installed in the piping, the procedure can be carried out with an interval of 4-5 years. Water needs to be changed annually, as it changes its structure and acquires properties that are aggressive with respect to metal.

It is best to experimentally calculate the required frequency of cleaning the heat exchanger. After the end of the heating season, you need to disassemble the boiler, remove the circuit and evaluate its condition. The plaque will tell you how long its thickness reaches a critical state.

Cleaning Methods

It is recommended to rinse the boiler heat exchanger immediately after the end of the heating season, when the coating did not have time to gain strength.To perform this procedure, one of the available methods is selected that is most suitable for the property owner.

There are such options for cleaning water circuits:

- Manual (mechanical). A simple and inexpensive way to get rid of scale and carbon deposits. The work uses improvised devices that can be found in every home. From the outside, the soot is scraped off with a knife or wire brush. Internal deposits are removed with a steel cable, one end of which is untwisted and made in the form of a brush. Such cables are used in brake systems of bicycles and gas flow control in motorcycle technology. After rough cleaning, which removes most of the contaminants, the product is recycled. It is soaking the tubes in any reagent that dissolves limescale and is safe for metal. The processing time is 20-25 minutes, depending on the concentration of the substance. The hotter it is, the better the effect will be achieved.

- Chemical. Washing the plate heat exchanger is carried out with household chemicals or self-cooking facilities. The advantage of this method is that the cleaning procedure can be performed without dismantling the tubes in the presence of a washing pump for heat exchangers. If this device is not yet available, the primary and secondary circuits are immersed in an acid solution, which is heated to a temperature of 40-60 degrees. Heating contributes to greater activation of chemicals. An acid-resistant tank must be used so that the reagent does not damage it. The soaking time is determined experimentally by analyzing the state of exfoliation or dissolution of plaque. In a weak solution, parts are boiled over low heat. The Laval product of Minsk production gives a good effect.

- Hydrodynamic. A pump is used to flush the heating system. Abrasive additives are added to the water, at a pressure of up to 2 bar the station drives it through the system. The filter is previously removed to ensure unhindered fluid movement. During the flushing process, it is necessary to change the pumping direction several times in order to better clean the channels. The cleaning effect is achieved by the rapid flow of fluid and its friction against the inner walls of the tubes. Using this method, they can be given their original state.

- Manual method

- Chemical

- Hydrodynamic

It is necessary to clean the contours carefully, without applying excessive efforts and without exerting pressure above the calculated one. Despite the fact that high-quality steel is used in the manufacture of heat exchangers, products can be easily damaged.

Flushing fluids

A wide range of chemicals in the form of liquids, gels and powders is presented in hardware stores. Almost all of them are based on acids. Most often, adipic, citric and sulfamic acid are used as a reagent.

The following brands have proven themselves best:

- Alfa;

- Baxi;

- Cip;

- Eliminate;

- Laval;

- Pump;

- Steeltex

- VV;

- Aquaprof;

- Alf.

Before buying, you should study the scope and conditions of use of the product, recommended brands of boilers, rules of use and warnings.

Washing machines

Designers have developed special devices so that you can clean the heat exchanger without removing it from the boiler body. The machine is connected to the nozzles, after which it starts to drive a reagent saturated with abrasive along the circuit. At the same time, increased pressure is created inside the tubes, and the temperature of the liquid rises to 60 degrees. The most popular household appliances are Ariston and Beretta. Products are compact and high performance. They can easily find a place in the pantry or in the closet.

It makes sense to purchase such equipment only if it is necessary to carry out cleaning annually, since the estimate for the booster and reagents can reach 38-60 thousand rubles. But the services of professionals will also cost a lot. In large cities, they cost 3-7 thousand rubles, and in the regions 2-4.5 thousand rubles. If you clean the boiler every year, the payback will begin in 6-10 years. Buying a booster is expensive, but you can reduce costs and even make a profit if you rent the unit or provide services to neighbors and friends for a moderate fee. It is enough to wash the heat exchanger yourself once to acquire the necessary skills. Since all boilers have almost the same device, there will be no problems with servicing other models.

Instructions for washing the heat exchanger with your own hands and at home

Before servicing the boiler, you need to release the coolant from the system, shut off the water, gas, disconnect it from electricity.

To work, you need the following property:

- screwdriver;

- indicator;

- plumbing pliers; pliers;

- paint brush, scraper;

- a metal brush, a thin cable with a brush, a toothbrush;

- safety glasses, rubber gloves;

- capacity of the appropriate size and volume;

- rags.

Water circuits should be cleaned in the following order:

- Remove the cover that covers the internal elements. Get a casing and thermal insulation.

- Disconnect the wires from the gas valve, remove the thermocouple;

- Drain the boiler. To do this, use the exhaust valve located in the lower part of the housing.

- Remove the fuel supply pipe;

- Remove the bolts from the burner, remove the assembly and lay it on a wide, stable base.

- Cover the electronic and switching units with cellophane in order to prevent water from entering them.

- With a metal, toothbrush, knife, scrape off the dirt on the outside of the device. Alternately clean the igniter, flame detector and automatic ignition.

- Get the secondary circuit, carry out similar actions with it.

- To carry out initial mechanical cleaning of internal channels with a cable with a brush.

- Knead a solution of citric acid. It is taken 200 g per 10 liters of water.

- Put the vessel on the stove, immerse heat exchangers in it, turn on the heating. Bring the solution to a boil and soak for 30 minutes.

- Get out the parts and wait for them to cool. Visually check the quality of the result. If plaque remains, remove it with a brush or re-boil.

- After cleaning the heat exchangers, rinse them several times with clean water to wash off all reagents.

- Assemble the unit in accordance with the installation sequence of the parts.

With a booster, everything is much simpler. It is only necessary to fill the device with reagent, connect it to the nozzles and turn it on. After washing, the solution is poured and replaced with clean water for rinsing.