A chimney pipe sandwich is a composite structure assembled from 2 pipe billets of various diameters, between which a layer of insulation made of polystyrene or mineral wool is placed. Its inner part is made of steel and has a special anti-corrosion coating. The outer casing is made on the basis of stainless steel or galvanized sheet.

What are sandwich kits made of?

In various samples of heating devices, sandwich pipes for chimneys are made of specially selected steel materials. The latter belong to the group of high alloy and stainless steels, ideally suited for the assembly of chemically resistant and refractory smoke exhaust pipes. There are three types of materials that are most often used as a basis:

- stainless steel with alloying additives;

- black metal;

- combined coating.

Each of these items will need to be considered separately.

Stainless steel

The main brands of stainless steel used to assemble a chimney sandwich differ in the composition of their additives.

- Stainless steel with an admixture of titanium. Metal is used in boilers and stoves fired with wood or pellets.

- Molybdenum stabilized stainless steel (AISI 316). Products made of such steel are used in installations fired by wood, gas or diesel fuel.

- Heat resistant steel grade AISI 304 with a high content of chromium and nickel. It is steady against thermal influences and chemically acidic environments.

The latter type of material is used in the manufacture of chimneys operated in high temperature mode.

Black metal

The material quickly loses its shape, due to its oxidation and gradual burning. To protect the surfaces, inexpensive galvanizing or special enamel is used, which increases resistance to acidic environments. The coating based on it will last a long time at operating temperatures of not more than 400 degrees. Enamelled pipes made of ferrous metal are used in heating columns, furnace designs of various classes, as well as in fireplaces and boilers. Unlike other materials, its surface is easily painted in various colors, which allows you to select it for the interiors of rooms, as well as the facades of houses and other buildings.

In order to reduce the cost of production, manufacturers launched the production of special structures that combine expensive stainless steel and ferrous metals. At the same time, they try to make a pipe from a high-quality stainless steel from the outside, and relatively cheap galvanization is used to make the inside. Between them is a layer of thermal insulation, which is used as basalt or ceramic wool. Such designs withstand temperatures from 600 to 1000 ° C.

Advantages and disadvantages

To assess the possibility of using sandwich pipes in the bath, you should familiarize yourself with their advantages and disadvantages. The disadvantages of chimneys assembled in the form of a sandwich structures include:

- the possibility of depressurization during long-term operation;

- the high cost of designs in comparison with brick counterparts;

- short service life (no more than 15 years).

The last drawback is associated with the use of materials of poor quality. Therefore, experts advise a responsible approach to the choice of a company that produces sandwich chimneys.

The following features are considered an advantage of these products:

- with reliable insulation in the chimney, good traction is always maintained;

- the multilayer structure of the structure does not allow the combustion products to cool, eliminating the possibility of the formation of condensate and soot;

- ease of installation, accessible even to a beginner;

- a large selection of modifications (angular, straight, etc.);

- minimum accumulation of soot.

Designs are lightweight and do not need a special foundation (foundation). They can be attached to the elements of the floors and walls, and also mounted directly on the heating equipment.

The correct selection of pipes for a specific type of fuel is possible after reading the table of their correspondence to a particular type of heating equipment. Reference data is widely available on the Internet and is available to anyone. When installing a sandwich pipe for a gas-fired boiler, they cost the cheapest option. For a Russian stove, built in a bathhouse and heated with firewood, it is recommended to choose products whose quality is beyond doubt.

Structural elements and their features

Chimneys for boiler rooms made of stainless steel sandwich versions thanks to a large selection of design solutions allow you to equip chimneys of various configurations.

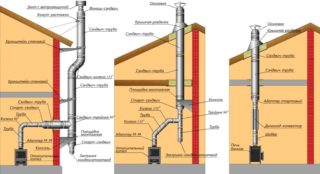

The main elements of the chimney channel:

- Straight pipe sections up to 1 meter long and with a diameter of 80-600 mm, used to assemble long sections of the chimney.

- Knees and special tees, used when it is necessary to lay the chimney through the walls or bring it out of the building.

- Through pipes designed to isolate the pipe when it is routed through the interfloor partitions and is also a fastener.

- Roofing, made in the form of a metal cone, mounted on the roof at a certain angle.

The last element allows you to hold a sandwich pipe through the roof, maintaining its tightness and guaranteeing the fire safety of the structure. Instead, a special silicone-based sealant is often used, which reliably protects this area from leakage.

How to choose the required diameter of the chimney

The diameter of the chimney structure is selected based on data on the power of the boiler or other heating equipment. For small installations with a power of less than 3.5 kW, pipes with a diameter of 8 cm are suitable. For equipment with this indicator of no more than 5.2 kW, workpieces with a diameter of 9.5 cm or more are needed, and at high powers, products with a typical size of about 110- 115 mm. At the same time, it is unacceptable to plan the restrictions of the chimney, the expansion, on the contrary, is welcome.

The diameter of the chimney structure is selected based on data on the power of the boiler or other heating equipment. For small installations with a power of less than 3.5 kW, pipes with a diameter of 8 cm are suitable. For equipment with this indicator of no more than 5.2 kW, workpieces with a diameter of 9.5 cm or more are needed, and at high powers, products with a typical size of about 110- 115 mm. At the same time, it is unacceptable to plan the restrictions of the chimney, the expansion, on the contrary, is welcome.

Another important parameter determining the choice of the diameter of the pipe sandwich for the stove is the thickness of the insulation layer, on average, 25-100 mm. With its increase, all the characteristics of the chimney improve, but at the same time the weight and cost increase. If it is necessary to replace or build up a small area, the user will have to select a segment of a suitable design manufactured by one or another manufacturer. As a rule, reliable joints cannot be obtained in this way. In some cases, due to the mismatch in typical sizes, the entire structure must be replaced.

System installation

Before installing the pipe for the sandwich furnace design, you need to familiarize yourself with the technical documentation and the requirements of TB. Compliance with the latter will eliminate the undesirable consequences of improper use of the sandwich product. Instructions for these operations include several steps.

Assembly of chimney elements

Assembly of the structure is always carried out according to the “bottom-up” scheme. At the same time, the chimneys are not directly connected to the heating unit. General procedure for operations:

- A piece of transitional steel pipe about a half meter long or a special adapter is connected to the heating device.

- If it is supposed to be led out through the wall in this place, a horizontal outlet with a slope of about 2 degrees is immediately mounted.

- Structural elements and walls located close to it are closed with a special protective screen or casing.

- The chimney must be installed in the direction of movement of the combustion waste - mounted on top of the pipe with the protection of the joint formed by heat-resistant sealant.

- All subsequent fragments are installed in the direction of condensation formation, which will exclude the possibility of its seeping in and protect the heat-insulating layer from getting wet.

During the installation, the sandwich pipes must be monitored so that they are securely fastened together by couplings, next to which a clamp is made to fix the structure to the wall (fastening step - at least 5 meters). To prevent lateral displacements, special wall brackets are installed after about two meters.

Organization of passage of ceiling and wall ceilings

When operating a chimney sandwich, the outer surface of the pipes heats up very much, which forces them to arrange additional insulation at the places where they pass through the building structures. At the same time, special attention is paid to ensuring that the joints of the workpieces do not coincide with the zones of wiring through walls and ceilings. The size of the hole under them is approximately 25 mm larger than the outer diameter of the pipe. The resulting gaps are filled with non-burning basalt wool. From above they are closed by heat-resistant material, which is later hidden under decorative decoration.

These measures help protect wooden structures from fire, while eliminating the possibility of deformation loads on the chimney during shrinkage of the building. For these purposes, special access nodes or unloading platforms are also used. They are made in the form of standard units that protect the piers and overlap it is heating and take on deformation loads.

Roof wiring

When a sandwich pipe is removed through a roofing, its tightness is violated, which forces additional protective measures to be taken. For these purposes, special devices and sealants are used. These parts have standardized dimensions, fixed tilt angles and are selected taking into account the parameters of a particular roof. The walls of the sandwich pipes should be located at a distance from flammable materials of at least 250-370 mm. To protect against water leaks, a special apron is arranged around the outlet, the edges of which are wound under the cover.

Installation above the roof surface

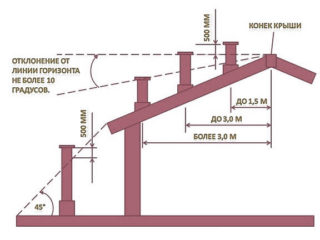

The height of the chimney sandwich design depends on the removal of its base to the ridge of the roof and must satisfy the following conditions:

- the pipe cannot rise above the ridge by more than 0.5 meters;

- removal of the top from the surface of a flat roof no more than 120 cm;

- the same parameter for the combined roof option is not more than 200 cm;

- if there is another building nearby, the upper cut of the chimney is made one and a half meters higher than its roof.

In the latter case, the pipe of non-standard height has to be additionally strengthened by means of special extensions.

Good draft in any chimney is obtained if the rules for its arrangement prescribed by the instruction are observed. The principle of its formation is based on the effect of ventilation or movement of air due to temperature differences in the middle part of the smoke channel and outside. Due to this gradation, the density of the inner layers is less than the same indicator for the external masses of cold air, which is the reason for the appearance of the pressure difference. Due to it, cold air is drawn into the furnace structure, while hot air rises through the chimney channel and is led out.

Operational Features

Upon completion of the installation, the chimney sandwich is a test run in operation, which allows to check the tightness of the joints and to make sure that the adjacent surfaces are not heated. During the first run of the system, slight smoke is sometimes observed and a characteristic smell of burnt oil, sealant and dust remains.

Maintenance of a chimney sandwich put into operation consists, first of all, in timely removal of soot accumulated in the pipes. When cleaning them, do not use special detergents. This operation is best entrusted to employees of an organization holding a license to carry out such work.