Gas equipment is classified as explosive, so its installation is given special attention. In addition to the correct connection to the energy supply line, it is switched with electric networks. Under certain conditions, technical documentation requires grounding of a gas boiler in a private house. You can do it yourself by organizing a circuit in the yard. It will increase the safety of the operation of the boiler several times.

Why are gas boilers grounded?

There are two main reasons why you should pay attention to connecting the steel housing of the heater to the ground bus:

- The electronic control systems of the installation are sensitive to various surface currents or static accumulating on metal parts during operation. The effect of such undesirable factors can be a malfunction in the processor or its failure.

- With possible gas leaks, the appearance of a spark in most cases leads to an explosion. Grounding neutralizes any potentials or leaks, eliminating the possibility of an accident.

It is necessary to ground both wall and floor boilers.

What types of grounding are

Grounding is a set of measures and technical means for the electrical connection of equipment housings and electrical installations to the ground. Such contact, as a rule, is carried out through a special device, which is based on a structure of steel elements.

Grounding can be done in two ways: natural and artificial. The quality of contact with them can be different, therefore, in each individual situation, it is necessary to measure the resistance of the ground device in order to determine its suitability for connection to equipment.

Natural

Under the natural understand grounding in the form of various building structures and supports made of metal, which are buried in the soil layer:

- various foundations, where reinforcement acts as a frame;

- underground utilities made of steel and other metals;

- relays supports, power supply lines, substations;

- armored cables - their shells;

- sometimes use railway rails.

In any case, the listed items are suitable for connection. The exception is reinforced concrete structures in contact with low humidity soil - less than 3%.

Artificial

This type of grounding is specially installed by a person for the specific purpose of protecting electrical and other devices. Most often, these are metal pins or pipes (electrodes) inserted into specially prepared soil and welded together.

Artificial zeroing has two functions. In the first case, it can be used for more stable operation of devices and protecting them from unwanted currents - called working. In another situation, it can be organized to prevent a person from getting electrical injuries. Such grounding is called protective.

Competent grounding of gas equipment

To connect the gas boiler to the soil, you can choose any type of grounding - both natural and artificial. In the first case, it is necessary to exclude from the list of possible options a steel sewer pipe, a heating main and barrels for storing combustible liquids.The heater must be connected at least at two points to the selected underground facility.

If the choice fell on an artificial ground electrode, before mounting it, they analyze the soil for moisture and electrical conductivity. With positive assessment results, you can independently assemble the structure or buy a finished one. In this case, the heater can be connected via one connecting bus.

Grounding materials for a gas boiler

There are norms and rules that indicate the parameters of the materials that are acceptable for the organization of the grounding device for a gas heater.

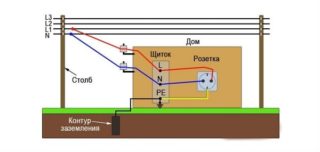

- The heater must be connected to the ground through a switchboard equipped with appropriate fittings.

- The cable for grounding (bus), going from the circuit in the ground to the electrical panel, must have a cross-sectional area of copper of at least 10 mm square, aluminum of at least 16 mm square, steel wire of at least 75 mm square.

- A vertically installed metal structure must be assembled from a pipe of a profile shape, an I-beam, a channel or a corner. They should be united by a tire tied to them by spot welding.

All metal structures are prohibited from covering with insulating or paint materials.

Installation rules and diagrams

According to regulatory requirements, the construction site should be selected near the house no closer than one meter to the foundation and no further than five meters from it. This place must be protected from any use and the presence of people in order to avoid electrical injuries.

Design and preparatory operations

At this stage, the shape of the ground loop is selected, which can take the form of a triangle with equal sides, a rectangle, a square, a polygon, or a straight line. The selected option is drawn directly on the soil surface in full size. In the case of a triangle, it is recommended to take side lengths within 2.5-0.5 meters.

To implement the project, it is necessary to prepare the following tools:

- apparatus for welding metal elements;

- electric grinder with cutting wheels for steel;

- hammer drill or punch for making holes for the cable.

In addition, you will need a heavy hammer or sledgehammer and a bayonet-type shovel.

Ground loop connection

The triangular ground loop is assembled as follows:

- On the drawn sides of the triangle, trenches are made to a depth of 0.7 meters and a width of 0.4 meters and one ditch for the cable from the nearest corner to the house.

- Pipes up to 2.5 meters long are driven into the corners so that their upper end is under a layer of soil that is poured 0.35 meters thick.

- Pipes are connected by welding using metal strips with parameters of 0.4x4 cm at least.

Further, a wire is fastened to the structure through a welded bolt.

Before burying the trenches, the conductivity of the circuit is checked. Its resistance to electric current should not exceed more than 10 ohms. If these figures are higher, it is necessary to add pins to the system. After achieving the optimal result, the soil from the ditches is returned to its place. It is desirable that it be more uniform, the composition did not have many stones.