The largest percentage of heat flows through roofing, wall and floor structures. The correct selection of the insulator will provide comfortable living conditions and protect the building from premature wear. Before buying, you need to calculate the dimensions of the mineral wool insulation in the plates, get acquainted with the manufacturers, labeling and advantages.

Properties of mineral wool in plates as a heater

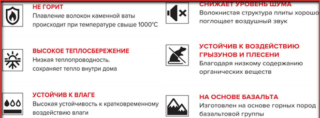

Mineral wool is a stone-based insulation that allows you to create thermal insulation of the structure. Lava rocks for the manufacture of material are heated and melted. Astringents are added to form and tighten the fibers. The final product retains the properties of basalt:

- Thermal conductivity from 0.03 to 0.04 W / m - the ability of the insulation to withstand temperature. With an indicator of mineral material 10 cm thick, comparable to 25 cm of timber, 200 cm of silicate brick and 117 cm of ceramic.

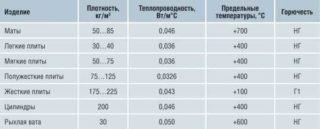

- Density - the indicator provides the use of plate isolate and averages 60-80 kg / m3. To equip the pitched roof, you need light slabs of 30-50 kg / m3, for a flat one - from 100 kg / m3. For industrial purposes, models from 160 kg / m3 are operated, which do not deform under the influence of an external load.

- Resistance to fire class NG. Basalt fibers do not ignite, do not spread fire, can heat up to +750 degrees. Non-combustible modifications are heated to 1000 degrees for 2 hours.

- Moisture absorption. Minplits have an indicator of 1-2%, i.e. do not absorb condensation and precipitation.

The thermal conductivity depends on the direction of the fibers. The best option is a chaotic location.

Advantages and disadvantages

Products are delivered coiled, and then cut. Mineral wool is suitable for all types of insulation work due to the advantages:

- soundproofing - can be laid in houses near the roadway and production halls;

- lack of cold bridges - the sheets do not shrink at the joints;

- special structure - the fibers are located in a chaotic direction or intertwined, which prevents the removal of warm air from the room;

- simplicity of laying - plates are easily cut with a knife or a hacksaw in place;

- wear resistance - the insulation retains its properties for 20-70 years;

- environmental friendliness - is made on the basis of natural basalt rocks.

The minuses include the difficulty of installation due to the large vapor permeability.

Why you need to know the dimensions of the mineral wool in the plates

Positive aspects and properties are ensured by the use of insulation in all areas of construction. In order to accurately calculate the amount of material for exterior or interior installation, you will need to know the basic plate sizes in m2 (squares).

When dimensions are taken into account

Insulation of the floor covering inside, the creation of external thermal insulation begins with the drawing up of a diagram and the procurement of materials. The parameters of mineral wool sheets need to know in order to:

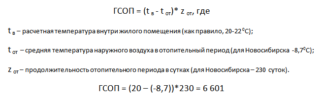

- creating thermal protection in accordance with the climate of the region;

- reduction of time for budgeting;

- selection of parameters when laying between the lags of the floor or attic;

- arrangement of the frame under the sheets in the case of external work.

Knowledge of the dimensions of the insulation layers eliminates the time spent on cutting during installation, the formation of unnecessary joints.

The standard size of the slab is 100x50 cm, but the number of pieces depends on the square of the building. Material thickness is achieved from 150 to 600 mm.When selecting dimensions, it is necessary to take into account the density index - the larger it is, the higher the probability of withstanding mechanical loads and the absence of deformation.

Plate parameters depending on the scope of use

Convenience of laying and high performance is characterized by mineral wool - the dimensions and scope of the material depend on its rigidity. Manufacturers release the following modifications:

- Light - with a density of 10 to 35 kg / m3. With their help, it is possible to insulate and protect the frame type of buildings from noise.

- Elastic - density from 35 to 120 kg / m3. The insulation is suitable for walls, its dimensions can be adjusted to the configuration of buildings. Minvata withstands minor external loads.

- Hard - the density indicator is 120-180 kg / m3, which is suitable for working with ventilation systems, organizing thermal protection of baths and industrial premises.

The width of the insulation is determined by the climatic features of the region. Buildings in the southern regions are executed in sheets of 120-180 mm wide, in the central - from 180 to 240 mm, in the northern - up to 360 mm.

The final parameters are determined by the type of insulated object.

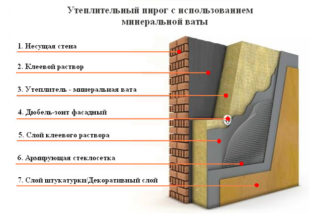

Facade slabs

Front products exclude the cost of materials during construction. They are mounted on a supporting frame, have good vapor permeability, do not shrink, and do not deform when exposed to temperature.

Front products exclude the cost of materials during construction. They are mounted on a supporting frame, have good vapor permeability, do not shrink, and do not deform when exposed to temperature.

The dimensions of the standard cut of mineral wool supplied in the slabs are 100x50x5 cm. For facades of an atypical configuration, material 120x60x20 mm is suitable.

Roofing slabs

Material parameters depend on the region in which the roof is insulated. You can calculate the parameters using the online calculator or independently, taking into account the standards for the climate zone, layer-by-layer thickness of the structure, thermal conductivity of each layer. When choosing manufacturers, you will need to take into account the type of roof structure.

The pitched roof is insulated with materials PAROS UNS 37 (610x1220x50 mm) and Extra (250x50 mm), Knauf (5500x1200x150 mm), Rocklight (1000 / 2000-500 / 600-50 / 100 mm), Techno (100x60x5 / 10 mm), Izover ( 1170x610x50 mm), Izovat (1000x600x50 / 100 mm).

For flat designs, the optimal options are the products of PAROS Rob (1200 / 1800x600 / 900/1200 mm), Monrock Max (2000x1200x50 / 200 mm), Technoruf N (1200x600x100 mm).

For work in attics and attics with elevations, a complex configuration, rolled glass wool with a density of 11-15 kg / m3 is suitable.

For walls

The suitable size of slab mineral wool is 120 cm long and 100 cm wide. The thickness of the product is 2.5-5 cm. The material is used for exterior and interior use, warming rooms with high humidity, ventilated facades and sandwich panels.

Rigid modifications with a density of 150 kg / m3 are suitable for laying on metal or reinforced concrete floors. For fire-fighting purposes, a material with a density of 200 kg / m3 is optimal.

On the walls of mineral wool laid vertically and horizontally.

For the floor

It is possible to isolate the floor from cold air with the help of products with dimensions 600x800 and density 100-150 kg / m3. Length and width are adjusted to the coating parameters.

Labeling Features

Manufacturers indicate on the packaging the name, size, release date of the insulation, fire resistance, thickness and type of lining. From the alphanumeric designations, you can understand the meanings:

- dynamic stiffness - sdi;

- dimensional stability upon reaching a certain temperature value - ds (t +);

- compressibility - (cpi);

- creep at the moment of compression - cc (i1 / i2 / y) σχ;

- a deformation load of 5 mm - (pl (5) i);

- moisture absorption during prolonged exposure - (wl (p));

- average noise figure - (awi).

The stiffness of the material is also marked with numbers and letters:

- semi-rigid for working on ceilings, flooring, inside the house - P-125;

- slabs for protection against noise and fire of roofs and attics - P-150;

- rigid for structures subject to deformation - ПЖ-175;

- light for horizontal structures, attics, pipe lines - P-75.

The maximum fiber length of the miniplate is not more than 5 cm.

Products for easy styling

Sometimes the size of stone wool in the slabs is not enough to insulate a vertical or inclined structure. In order to simplify the installation of the system, mats with additional layers are used:

- Bituminous. Allows you to create an additional base for roofing roofing.

- With polymer or fiberglass lamination. Facilitate the "dry" insulation or arrangement of sandwich systems. Fiberglass prevents the blowing of fibers, and polystyrene blocks the ingress of moisture.

- With section differences. Used to perform the slope of the pitched roof. With such a plate, water drains faster.

- Slatted. The sheet is distinguished by a perpendicular arrangement of fibers, due to which elasticity is achieved, tensile strength is increased.

- Double basalt. Allows you to protect the house by "wet" technology from heat leaks. The top coating is hard, does not allow the product to deform during installation. The lower elastic part provides the density of abutment of the material to the wall.

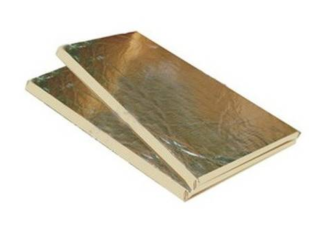

- With foil. Additional fiberglass reinforcement of foam-foam models eliminates the penetration of condensate. Using the material, you can insulate a residential attic or loggia.

Manufacturers mark sides for convenience.

Popular Slab Mineral Producers

When choosing a thermal insulation material, it should be noted that the dimensions of the finished mineral wool supplied in the plates differ depending on the manufacturer. Domestic users prefer several brands.

When choosing a thermal insulation material, it should be noted that the dimensions of the finished mineral wool supplied in the plates differ depending on the manufacturer. Domestic users prefer several brands.

Isover - Certified Affordable Products

Technological brand solutions allow you to choose several options:

- Frame P-32 - the size of the slab is 1170x670 mm. Thickness is 40-150 cm.

- Frame P-34 - have a thickness of 40-200 mm, the length and width parameters are 1170x565 mm.

- Rigid - the minimum thickness of the product is 30 mm, dimensions - 1550x1180 mm.

The manufacturer indicates how many sheets are contained in the package.

Knauf - quality and reliable products

Knauf thermal insulation products are made on the basis of basalt and fiberglass, supplied in rolls and slabs, suitable for roofing, partitions, acoustic protection. The width and length features of the mineral wool depend on the series:

Knauf thermal insulation products are made on the basis of basalt and fiberglass, supplied in rolls and slabs, suitable for roofing, partitions, acoustic protection. The width and length features of the mineral wool depend on the series:

- Cottage - produced in rolls of 6148x1220 mm and plates of 1230x610 mm. The thickness of the materials is 5 cm.

- Cottage + - an insulator in tiled form 10 cm thick with dimensions 1230x610 mm.

- TeploDom. The plates are made using 3D elasticity technology, have a length of 1230 or 6148 mm, a width of 610 or 1220 mm, and a thickness of 5 or 10 cm.

- Insulation. It includes the Thermoplate 037 (1250х600 cm) line, the Thermo roll 040 - roll mats (1200х10 000 mm).

The acoustic series has a two-layer construction. The thickness of each layer is 5 cm, the width is 61 cm, and the length indicator is 750 cm.

TechnoNIKOL - Russian products for beginners and professionals

The Technonikol company produces heaters for professional work, home improvement and summer cottages. Mineral wool has the shape of a plate in soft, hard and semi-soft versions.

The Technonikol company produces heaters for professional work, home improvement and summer cottages. Mineral wool has the shape of a plate in soft, hard and semi-soft versions.

The standard size is 120x60x50 cm. The material can have a thickness of 4-25 cm. The Technovent series is designed for facades, Rocklight for attics, floors and ceilings, Basalite for roofs and attics.

Rockwool - versatile material

Non-combustible, moisture-proof Rockwool mineral wool increases energy efficiency at home. Several series are presented on the Russian market:

Non-combustible, moisture-proof Rockwool mineral wool increases energy efficiency at home. Several series are presented on the Russian market:

- Light Butts Scandic. Hydrophobized plates in sizes 800x600x50 / 100 mm and 1200x600x100 / 150 mm.

- Light Butts. Two-layer product (smooth and rough surface) for roofs, ceilings, interior work. The size is one - 1000x600x50 / 100 mm.

- Flor Butts. Rigid sheets for flooring (floors on the ground, above the basement, reinforced concrete base). Dimensions are 1000x600x25 mm.

- Sauna Butts. Bioresistant modifications with aluminum foil. The miniplate has a thickness of 50-100 mm, length and width - 1000x500 mm.

Rockwool slabs almost do not shrink during operation.

Paroc - many thermal insulation options

The Finnish brand produces materials for construction and industry. Warming of a private house can be done with the help of rulers:

The Finnish brand produces materials for construction and industry. Warming of a private house can be done with the help of rulers:

- Extra.Material in sizes 1320x565x50 / 150, 1200x600x50 / 100 and 1170x610x42 / 150 mm is suitable for frame structures.

- UNS 37 with a thickness of 35-175 mm. Designed for floors and walls. Dimensions of plates - 1220x610x50-150 mm.

- InWall - for all types of buildings. Fire-retardant and moisture-proof insulation is distinguished by length and width parameters of 1200x600 mm, thickness - from 30 to 250 mm.

- Linio - produced in several series, designed for plastered facades. The length and width of the slab -1200x600 mm, thickness - from 30 to 250 mm.

- ROB - flat roof models. Available in sizes 1200-1800x600x20-30 mm, 1200-1800x900x20-30 mm and 1800x1200x20-30 mm.

- GRS - material for flooring of the first floor, foundation, basement. The thickness of the products ranges from 50 to 200 mm, indicators of width and length - 600 and 1200 mm.

Elastic plates The park is easily cut with a hacksaw for metal or an office knife.

Mineral wool slab is a universal material that solves the problems of thermal insulation of residential, office and industrial premises. Depending on the size and thickness, the product is laid on a flat, curved surface in a short time. Products of domestic and foreign brands are selected according to parameters, production series and the presence of an additional layer.