If you live in a rural village, a country house or in the presence of a summer residence, it makes no sense to spend money on expensive heating equipment. Save on materials and improper household appliances. From them you can assemble a heating boiler for a private house with your own hands. Before work, it is worth studying the types of units and a step-by-step algorithm of actions.

Varieties of heating boilers

The range of heating units allows you to choose the installation according to the financial capabilities and personal preferences of the owners. When choosing a device, it is advisable to pay attention to the type of fuel.

The specifics of solid fuel models

In rural areas or if you want to save on fuel, you can install a wood, briquette, coal unit. The line of solid fuel models also includes sawdust and coke boilers. All devices are environmentally friendly and safe. By the principle of work there are:

- Classic - heat the room through direct burning of fuel materials. Bookmark is made in 5-6 hours.

- Pyrolysis - operate on the principle of afterburning of gas released in the combustion chamber. Fuel is loaded every 12-14 hours.

When making a model on solid fuel yourself, you need to organize a chimney with high-quality traction, a place for fuel.

Care of solid fuel units consists in the periodic cleaning of the combustion compartment.

Characteristics of electric boilers

The electric type of heaters is compact, silent, affordable. Products differ in the type of heating elements:

- At the heating elements. Modifications with a tubular heater are suitable for floor and wall installation. The disadvantage is the formation of scale on the heater.

- On the electrodes. Suitable for a system of 1-2 batteries or a large room. The devices are efficient, quickly heat water, but are sensitive to its chemical composition.

- Induction. They quickly heat up any type of coolant, have an efficiency of 100%, and are equipped with an overheat protection system.

Induction equipment is the most expensive among electrical models.

Features of gas devices

The gas heater can be selected according to several parameters:

- The number of circuits. Single-circuit options work only for heating, double-circuit, in addition to heating, are connected to the DHW system.

- The method of heating water. A flowing column or a built-in boiler of 150-180 liters is used.

- The number of double-circuit heat exchangers. A single bithermic element heats water for heating and domestic hot water. In units with two heat exchangers, the primary one is used for heating, the secondary - for hot water supply.

- Type of combustion chamber. The open draft boiler is installed in a separate ventilated room and is equipped with a vertical chimney, as takes air masses in a natural way. Closed equipment is equipped with a coaxial chimney located horizontally, and air is supplied to it by a fan or cooler.

- The method of ignition. Electric is used for appliances burning inconsistently. Modifications with pyezovy ignition are included manually.

The best option for a private house is a condensation model, which has a water economizer.

Oil heating boilers

The diesel heating unit is installed in the country, in a country or private house in accordance with the requirements of fire safety. It is located in a special room with high-quality ventilation or a powerful exhaust hood. Special containers are used to store liquid fuel. The advantages of liquid fuel options are high power and productivity.

DIY tools and materials

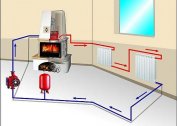

In the private sector or in the country, the easiest way is to make a boiler for a water system. To power a home-made installation, you can use only electricity or solid fuel.

The simplest option would be a classic wood burning direct burning boiler. For him, you need such materials:

- alloy steel (stainless steel) 5 mm in thickness for the body and 7 mm in thickness for grate;

- ordinary steel St20 3 mm thick for a water jacket;

- smoke tubes with a diameter of 48-76 mm from St20;

- metal strips or corner profiles 50x50 for stiffeners;

- asbestos, basalt fiber for flame retardant insulation;

- asbestos cord for porch doors;

- threaded rods with hinges for loops;

- nozzles on pens made of hard rubber or textolite.

For manufacturing, tools will also be needed:

- welding machine;

- grinder and discs for cutting and grinding;

- electric drill with drills for metal;

- gas keys No. 1 and No. 2;

- hammer, pliers, square;

- keys (open-end or folding), screwdrivers.

To protect you need to use a welding mask, glasses, gloves.

Cutting parts and installing the boiler

Before starting the assembly of home-made wood-fired boilers, you will need to perform a drawing taking into account the features of the heating system for a private house. Products have the form of 2 compartments located "nesting doll". The outer box is a combustion chamber, the inner one is a reservoir for heating water. Elements are not communicated with each other.

Preparation of parts is performed as follows:

- The aggregate walls are cut from a sheet of metal.

- Partitions for the stove are made of metal 10-12 mm thick.

- A hole for a chimney with a diameter of 10 cm is made on the upper part.

- The sides are welded to the bottom, and then, on vertical parts, metal strips 3 cm wide under the grate.

- On the side parts are fixed support strips for partitions.

- They are made and installed on the door hinges, sashes for the furnace and ash pan are cut out.

- Partitions in the form of a labyrinth are attached - they will increase the heating efficiency by creating a barrier to air.

- A sleeve of 20 cm high is welded onto the lid with a hole under the chimney.

- The lid is welded to the body, a chimney is mounted.

Installation of the device is carried out in a selected place with an external cladding with fireclay bricks. The masonry should be 15-20 cm from the body.

Creating a boiler from a pipe

The boiler is made of wood or coal from a pipe and has a U-shaped shape. On the top there is a fitting, on the bottom there is a return. The unit is easy to do if you follow the step by step recommendations:

- Selection of tools and materials. You will need several metal pipes with a diameter of 1.5-2 inches, as well as a welding inverter, a grinder with a nozzle for cutting metal, a tape measure, a hammer.

- Cut a metal pipe in size.

- Welding the edges of the lower part in the form of the letter P.

- Burning holes for vertical racks.

- Arrangement of vertical elements from corners or pipes of smaller diameter.

- Making the upper part from pipes of the same diameter and holes for vertical parts.

- Welding the fitting to the supply pipe and air vent.

- Performing a firebox and blowing. In the pipe, rectangular openings of 20x10 cm for the furnace and 20x3 cm for the blower are cut.

The tightness of the device depends on the quality of the weld.

Execution of an electrical model

A do-it-yourself electric boiler for heating a house is made using such materials and tools:

- angle grinder or grinder;

- welding inverter apparatus;

- multimeter;

- sheet steel with a thickness of 2 mm;

- adapters for connection to the system;

- TENOV - heaters can be bought or assembled independently;

- steel pipe 159 mm in diameter and 50-60 cm long.

The algorithm for creating an electric type aggregate consists of the following steps:

- The implementation of the pipe connection to the system of pipes. You will need 3 elements of 3, 2 and 1.5 inches in diameter.

- Making a container for a tank from a pipe. Make a marking, cut a hole through it and process the seams.

- Welding nozzles to holes.

- Cutting from a pipe of a larger diameter two circles under the heating compartment.

- Welding to the top of a 1.25-inch diameter nozzle.

- Making space for the heater. Two holes are made in the bottom.

- Connecting the boiler using pipes to the system.

- Installation of a low-power heating element with a temperature regulator on the upper pipe.

In the absence of skills to independently connect the boiler to the network is not recommended.

Features of the assembly of heating elements

It is possible to weld a boiler with heaters on the basis of a purchased heater with a power of 1-1.5 kW. You will also need a pipe, flanges with fasteners and two pieces of a water pipe.

At the bottom of the boiler from a piece of steel pipe, made by hand, install the heater by the flange method. At the top there will be an expansion tank with a hole for filling the water. Water pipes connect to the return and feed.

Procedure for checking and starting the device

A homemade boiler starts only when the system is filled with water, inspection of wiring and connections. In the presence of forced circulation, a pump is installed for uniform heating of the coolant. In systems with natural circulation, a slight slope is made at the return exit site. Pinched or torn cables of the power line are replaced or re-insulated so that the heater does not fail. To protect against voltage fluctuations, an RCD is mounted.

The heating unit is cleaned of dust and dirt, and then painted with a heat-resistant agent. Before applying the paint, it is necessary to sand and prime the surface. The coating is applied in 2 layers.

Water is supplied in the communication so that there are no air congestion. To control airing use faucets on radiators. Next, turn on the boiler in the network, expect warming up. The water temperature is checked with a multimeter.

You can independently make a solid fuel boiler from sheet metal or an electric one from a professional pipe. At the cost of materials and labor, the design will cost less than a special unit. Minus of the device - possible damage and malfunctions in the system if the installation is not performed correctly.