To heat a country cottage or a cottage, it is useful to have an ordinary firebox on wood available. The most important advantage of such a heating device is its absolute autonomy and independence from gas or electricity. In case of unforeseen outages, the house will still be heated. Types of furnaces are diverse, so it is important to understand their classification in order to choose the best design option for yourself.

Furnace classification

In the past, the stove was the only source of heat generation in households and enterprises. Over the years, she has undergone many changes. In all countries where there is a change of seasons, you can meet your own version of such a heating system. The most successful projects became widely known and were borrowed for mass use.

By country of origin

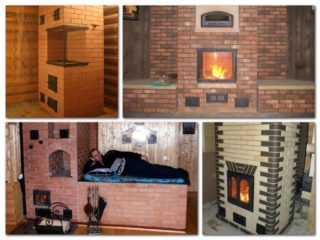

Due to its efficiency, convenience, the following brick furnaces are most widely used:

- Russian - differs in a complex design and large size. It has a two-zone type firebox, where one part (bakery) serves for cooking, the second (firebox) - for burning wood.

- Dutch - a simple heating system in construction. Initially, it served only as a means of heating. Later upgrades allowed the installation of a hob.

- Swedish - a modification of the Dutch design. An efficient multifunctional device with a stove, oven, place for drying things and a winding chimney.

According to destination

All known types of stoves can be divided into options for heating a room where there is no hob, cooking devices with a stove, oven and combined designs that are universal. In some cases, they are installed for decorative purposes and are not used for their intended purpose due to low efficiency.

By type of material

The most common material for making a firebox is refractory brick; most models are laid out from it. Potbelly stoves are made of metal - simple welded units with a direct chimney and low efficiency. There are options made of stone.

Wall thickness

The greater the thickness of the heated surface of the masonry, the greater the heat capacity it has. The heat capacity makes it possible to heat the device less often, but at the same time the dwelling will be heated by the gradual release of thermal energy to the room.

Russian belongs to thick-walled constructions; after good heating, it can be ignited for several days. The thickness of thin-walled furnaces may not exceed 7 cm. Such a heater is able to quickly warm up to almost 1000 degrees Celsius, but after attenuation the room will cool down within 3 hours.

Any type of brick oven is not designed for continuous burning.

By type of chimney

Chimneys are straight vertical when the combustion products from the chamber immediately fall into the pipe. Such designs usually provide dampers to regulate traction, otherwise most of the heat will evaporate without benefit. People call such structures spans.

Multichannel (parallel or serial) systems are more efficient. They contribute to a greater warming of the very mass of the structure and the pipe where the chimney passes.

Sometimes they make combined designs, combining spans with a multi-pass chimney - the so-called summer and winter course.

By furnace design

The heating chamber of the heating device is closed in almost all known models. Open furnace systems are used in the construction of fireplaces and other similar structures (barbecue, barbecue), built on their principle.

In shape

In terms of appearance there are no restrictions for imagination. Angular, in the form of rectangles or squares, polygonal, rounded and oval options can be arranged. There are masonry irregular shapes, various sunbeds.

Features and basic elements of furnaces

A brick or stone structure is characterized by the following features:

- high level of thermal conductivity;

- the ability to retain heat in its entire mass, and then give it away gradually;

- mechanical strength and heavy weight;

- exactingness to exact observance of construction of channels and furnace compartment.

The main elements of the structure are:

- a reinforced concrete base or foundation capable of supporting the mass of the heating unit;

- a massive skeleton, in which there are all the functional elements: a furnace, a hob, a grate with a blower, a system of smoke exhaust channels, a system of inspection dampers for cleaning the channels;

- smoke exhaust pipe.

You can not connect the foundation of a folded massif with the foundation of housing construction in order to avoid the destruction of the latter.

What are heating constructions made of?

In the manufacture of the furnace, especially its critical parts, it is recommended to use exclusively red brick of the highest grade with a size of 6.5x12x25 cm. It should have the correct geometric parameters, no defects and impregnated particles of lime.

For a bunch of masonry, use ordinary red clay or special mixtures based on it. It is desirable that the clay has as high a melting and sintering temperature as possible.

As auxiliary materials, ceramics, asbestos cement, hydro- and heat-insulating materials, as well as specialized wire are used.

Features of the construction of the wood system

A stone or brick roaster has a large mass, therefore, under such a structure, a foundation is necessarily laid. The dimensions and power of the base directly depend on the size and total mass of the masonry.

All rows to the level of direct contact with high temperatures can be performed on cement mortar, then the masonry is carried out on a special thermally stable mixture or refractory clay.

The progress of the structure, the proportions of the furnace cannot be built by eye, for this use drawings with the recommended sizes. The material of the manufacture of the chimney must not have nicks, cracks, strong irregularities.

The contact areas of the unit with combustible materials must be protected from non-combustible heat insulators.

Criteria for choosing a stove for the home

Equipping wood heating in the house, it is necessary to analyze several points:

- The purpose of the brazier - the most versatile is the combined construction, which is designed to prepare and heat the room, various models of Swedes will be an excellent option here.

- Overall dimensions - for large rooms, large structures of the Russian type will not fit, and the Dutch will not heat spacious rooms.

- The type of fuel - this largely depends on the duration of the combustion of the furnace - the longer the unit is in operation, the more refractory its components must be.

Analyzing the types of bath stoves, it is worth paying attention to metal products. They are compact, do not require the construction of a foundation, quickly warm up the room and will cost the owner much cheaper than those laid out of brick.