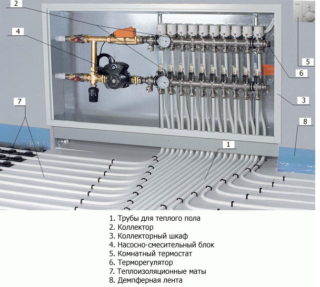

Installation of a warm floor involves the installation of a distribution unit that provides optimal circulation of hot water. In order for the water heated floor to function optimally, a cabinet for the collector is needed. It connects pipes and elements. In addition, the aesthetic side wins: the water meters, pipes, wiring and valves are masked.

Types of manifold cabinets

Depending on the design features, collector cabinets for heating are divided into two types: built-in and outdoor. The side segments of the products are adjustable in depth, which makes it possible to mount on walls with different thickness indicators. On both sides of the box there are service entrances for pipes of different sections, which simplifies installation.

Embedded

The built-in cabinet for the underfloor heating manifold is represented by a segment of models installed in niches under the plasterboard sheathing, as well as inside building structures.

Cabinets are equipped with removable covers. In the sidewalls there are slots designed to output pipes and fasteners. The boxes are equipped with extendable legs.

Outdoor

The need to install an external box arises if the thickness of the partition or wall at the installation site is less than its size. The restriction on the arrangement of niches is explained by the risk of structural failure of the load-bearing wall, which entails the weakening of the multi-storey building as a whole. Sometimes niche sampling is not possible due to the high hardness of the material. In this case, outdoor models are indispensable. The price for them is higher, since side walls and the use of additional elements for installation and fastening are required.

Outdoor manifold cabinets can be wall and floor depending on the mounting method. Wall-mounted boxes are simplified installation. Removing the outer lining is not required. There are also legs. The product has an aesthetic appearance and remains invisible after installation.

Floor models are used if it is necessary to heat a large room.

Specifications

The cases of the built-in ducts are made of heat-resistant high-quality plastic or steel sheets 1 mm thick. Protection against corrosion is the coating of the housing with special powder or polymer means. The standard color is white, beige or gray.

The basis for the manufacture of wall models is metal that has not been galvanized. The product is fully painted. Pipe outlets are covered with metal plates. Boxes of this type are distinguished by easy access to the distribution node. Models are equipped with a heating controller, which allows monitoring the operation of appliances. The sizes of products in this series are identical to the sizes of embedded species.

When choosing a collector cabinet for a warm floor, it is important that the number of conclusions match the actual layout. The output and supply lines of the heating system are also taken into account. The box should accommodate basic and additional devices. An important role is played by the type and direction of opening the doors. Removable elements are installed on the left or right depending on consumer needs.

Dimensions

Built-in and wall cabinets have the same dimensions. The depth of the devices is 12 cm, the height is 65 cm, and the width is from 46.5 cm to 19 cm. The height is regulated by legs that are able to raise the product by 10 cm.

Manifold cabinet functions

A manifold cabinet for heating is a practical product. Installation of equipment solves the problem of placing the components of the system in the apartment. The neatly painted door gives the room an aesthetic appearance.

The use of the box allows you to:

- reduce the number of pipes needed for the functioning of a warm floor;

- eliminate the need to pull the pipes from the heater;

- carry out repairs or upgrade the system, as it provides unhindered access to the guide loop.

Safety is considered the top priority. A door with a key makes it possible to enclose a cabinet with expensive appliances from children.

Cabinet sizes and accessories

Product sizes are standard. The segment of some companies is represented by compact models whose width is 45 cm and the depth is 18 cm.

The standard list of components includes:

- Body. Represents a box from stainless steel or plastic. The back wall is missing. The sides and bottom panel are provided with slots for pipes.

- Fasteners. The mechanism is installed based on the location of the structure - on the surface or in the center of the wall. Spacers or anchors are used for fastening. Some models have fixed brackets and clips.

- Doors They protect the internal devices of the heating system from damage and prohibited entry. Attached by hinges. Doors are equipped with a lock or latch.

Box for the distribution node can be made independently. But do-it-yourself collection is not justified, since the price of most devices on the market is low. It is recommended to purchase finished products.

Installation and location

When mounting the built-in type of cabinet, a niche is required. If the recess was made during the construction of the premises, installation difficulties will not arise.

The following installation steps are highlighted:

- wall marking is planned for the pipe collection;

- through a wall chaser, holes are made in the wall for the cabinet;

- the box is attached to the sides in the wall niche with the help of anchors;

- contours are held together;

- after installing the heating distribution unit, the circuit is closed and checked for leaks;

- the gap between the wall and the cabinet is smeared with mortar, and then putty.

Installation of wall models is easier:

- places for fasteners are marked on the walls;

- holes for anchors are drilled with a puncher;

- the box is fixed by means of screws;

- the cabinet is aligned with the marked tags;

- collector is installed;

- the circuit is connected;

- a trial run of the system is performed.

Installation of cabinets for the heating manifold is quick. When mounting the device, the recesses in the wall do not become an obstacle. During installation, a detailed drawing helps, compiled taking into account the size of the box, its technical features, as well as the locations of communications.

Optimum performance is achieved when the product is installed in the middle of a heated room near the floor surface. Particular attention is paid to the evenness of the working base. Structures that hold the device should not have distortions in level.

The cabinet for the heating system manifold is connected taking into account the rise in the floor level. After mounting the box, a supply (input) and return (return) pipe is introduced into it. The inlet pipe brings hot water to the circuit. The return pipe drains the cooled liquid into the boiler for subsequent heating. The place for the cabinet of the distribution unit is selected so that the contours of the heating system have the same length indicators, but not more than 70 meters.

When choosing the optimal location, it is recommended to seek the help of professionals.Errors during installation are fraught with excessive flow of pipes or deviation in the pressure indicators of the heating system.

Popular manufacturers

Built-in and outdoor models of manifold cabinets are made to order. It is also justified to purchase factory products with standard markers that meet the technical requirements of the heating system.

The main manufacturers supplying high-quality products to the Russian market are:

The Italian company Valtec. It produces products in standard and modified configurations. The design of the cabinets is attractive. Corrosion-resistant coating is inherent in high quality.

Russian company Grota. Exists in the market since 1996. The company is engaged in the sale of stylish sheet steel products that are distinguished by an acceptable cost. Cabinets are hot-dip galvanized.

The domestic manufacturer "Impulse" with the brand name Wester, which manufactures powder-coated cabinets. Previously, a phosphate film is applied to the body.

GorMax company. It produces products of high quality steel with a thickness of 1 mm. All components of the cabinet are painted by powder spraying. The side walls contain laser cuts for connecting pipes. DIN rails are installed in the cabinets, allowing you to mount the equipment over the entire height and width.

- Grota

- GorMax

- Pulse

The warranty on the above products is set by the manufacturer. All conditions must be clarified when buying a box. You should also familiarize yourself with the certificate and the document confirming the right to sale.

Regardless of the brand, when choosing a cabinet for a heating distribution unit, attention should be paid to the quality of the following components:

- surface;

- fasteners;

- Doors

- locks.

Companies that produce quality products do not save on packaging material. The sturdy corrugated cardboard of which the box is made protects the box for the heating manifold and parts from damage during transport.