Thermal insulation of pipes allows to reduce energy consumption, to prevent freezing of utility networks in the cold season. Insulators for highways should be resistant to moisture, chemical and mechanical stress. The listed qualities are possessed by Thermaflex. The material is made of foamed polyethylene, reduces heat loss by 88%.

Description of insulation for Thermaflex pipes

Thermal insulation Thermaflex protects the surface of pipes from contact with the external environment. Heater is made by foaming polyethylene with hydrocarbons. It turns out a material with a finely porous structure. Gas-filled cells are the same size. The canvas is characterized by elasticity and resilience. Synthetic insulation is available in the form of cylindrical shells of various diameters and rolls. It does not contain freon. Thermal insulation refers to low combustible materials. It is resistant to ultraviolet radiation, does not lose elasticity in the cold.

Material Specifications

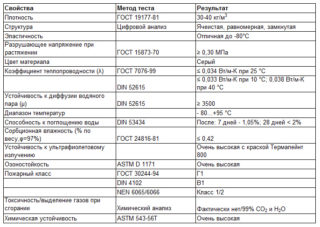

The effectiveness of Thermaflex pipe thermal insulation is determined by its technical characteristics:

- thermal conductivity - 0.034-0.035W / m * K;

- working temperature - from -80 ° C to + 95 ° C;

- density - 20-40 kg / m3;

- vapor permeability - about 0;

- maximum tensile load - 30 MPa;

- water absorption is minimal;

- combustibility group - G1-G2;

The color is gray. The structure of the material is uniform, cellular. It does not contain toxic impurities, therefore it is environmentally friendly. At low temperatures, elasticity is maintained.

Advantages and disadvantages

Thermoflex - insulation for pipes, the characteristics of which provide high insulating ability. The main advantages of the material:

- Low thermal conductivity. A honeycomb, gas-filled structure provides minimal ability to conduct heat.

- Moisture resistant. The use of specific additives and additives in the manufacturing process allows to obtain a material with a low sorption characteristic. The absence of wetting prevents the loss of thermal insulation qualities.

- Biological and chemical inertness. Polyethylene is not affected by biological factors; fungi and mold do not multiply on it. Synthetic material is able to withstand the aggressive effects of chemicals. It is resistant to acids, alkalis, alcohol, gasoline.

- Corrosion protection. Thermaflex isolates the surface of pipes from external influences and prevents condensation. Avoid moisture increase helps low vapor permeability of the material.

- Easy installation. The insulating cylinders are ready for use; they are easily put on pipes due to the longitudinal section. After installation, it is enough to seal the seam with special Thermaflex glue. The joints of the insulation sections are connected with a self-adhesive tape.

- Durability. The elastic material retains its initial shape for a long time. Foamed polyethylene is designed for use up to 50 years.

Disadvantages:

- Under the influence of a high load, the material is crushed, its insulating properties deteriorate.

- Foamed polyethylene does not burn, but when heated, it starts to emit caustic smoke.

All Thermaflex products have certificates of compliance and environmental safety.

Linear dimensions

The insulation is made in the form of gray elastic pipes. Their standard length is 2 m. The material is sold in bays of 10-50 m. The inner diameter of the products is designed for popular pipe parameters - from 6 to 150 mm. The wall thickness is 6-32 mm.

Sheet insulation is offered in rolls with a width of 1 m, a length of 30 to 200 m. The thickness of the web is from 5 to 30 mm.

Area of use

Thermal insulation Thermaflex is used as heat and sound insulation of pipelines and other communication systems. The material is in demand in private and industrial construction. Scope of its use:

- hot and cold water supply of private and multi-storey buildings;

- heating system;

- internal and external sewerage;

- ventilation ducts;

- refrigeration units;

- industrial tanks for storing liquids.

Environmentally friendly insulation can be used in children's and medical institutions, food and pharmaceutical industries. Thanks to the numerous closed gas pores, it prevents the movement of heat and sound waves. Pipe cylinders, wearing highways and risers reduce the noise level in apartments. They isolate metal and polymer structures laid along the walls.

The main models of insulation for pipes Thermaflex

Products under the Thermaflex brand are well-deserved among professional installers and owners of private houses.

Thermaflex FRZ

Thermaflex FRZ type heat-insulating pipes made of foamed polyethylene are used in water supply, heating, insulation of air ducts and refrigeration units. A universal product designed for new and reconstructed engineering networks. The hollow tube has a technological cut for easy installation. The density of foamed polyethylene is 35-40 kg / m3. Flexible pieces are made 2 m long. Internal diameter is from 12 to 159 mm. The thickness of the insulation is 6-30 mm. Recommended for installation on structures with positive and negative surface temperatures.

Thermaflex ac

Insulation material is most often used in refrigeration and air conditioning systems, as well as plumbing and heating networks. It is resistant to getting wet, aggressive compounds and diffuse vapor, ultraviolet. The tube has a low coefficient of thermal conductivity - 0.036 W / m * K, retains elasticity up to -80 ° C. Hollow cylinders in black. Their diameter is 6-114 mm, wall thickness 6-25 mm. For installation you will need special glue and adhesive tape.

Thermaflex Ultra M

The pipe insulation of the Ultra M series is based on foamed polyolefin. To increase the mechanical strength and UV resistance, the insulation is coated with a polymer layer. Heat-insulating tubes are recommended for installation in medical and child care facilities. For quick and reliable installation, they are equipped with a plastic latch. The products are manufactured in 2 m segments, they are silver-colored, density 35-40 kg / m3. The thickness of products of different diameters does not change, its parameter is one - 13 mm. The use of insulation is possible at a maximum temperature of 100 ° C.

Thermaeco

Thermaflex insulation is made with the expectation of the parameters of steel and plastic pipes. The maximum design temperature of the insulated surface is 95 ° C. The material is characterized by the lowest density (25-35 kg / m3) and high environmental safety indicators. The use of domestic raw materials in the production process allowed to reduce the cost of insulation. Elastic tubes are available in dark gray, the size range from 6 to 159 mm.

Thermasmart pro

A distinctive feature of the insulating material is the use of thermoplastic foam as a raw material. It turns out insulation with small closed cells, which has increased resistance to external influences. It is designed for systems requiring high thermal insulation performance. The product maintains its performance over a wide temperature range. The material serves as an acoustic noise barrier in utility networks. It is designed for pipes with a diameter of 6-114 mm. A significant plus of Thermasmart Pro is its long service life.

Thermasheet

Canvases of sheet insulation are indispensable for objects of large area.The scope of their application is ventilation ducts, heating pipes of significant diameter, refrigeration and air conditioning units, tanks. Thermal insulation Thermasheet is designed for a wide temperature range from -80 ° C to 100 ° C. The material does not pass diffuse vapor, prevents the formation of condensate on the insulated surface. It can be used as sound insulation, canvases reduce the noise level by 24 dB. Thermaflex adhesive is required to fix the insulation.

Thermasheet alu stukko

Thermal insulation with an external aluminum coating provides a high level of protection against heat loss, mechanical damage and the influence of ultraviolet radiation. The thickness of the sheets is 5-25 mm. Aluminum is applied with a layer of 0, 1 mm. Products are sold in the form of rolls. Its installation is carried out using glue and aluminum tape. Insulation is recommended for utility networks with high requirements for aesthetics and hygiene.

Thermoflex pipe thermal insulation is reliable, durable and safe. The technology of its installation is simple and does not require special knowledge and tools.