Brick houses are solid and durable. Natural material provides natural air exchange, does not burn, looks attractive without additional decoration. One of the minuses of brick blocks is high thermal conductivity. In addition, thermal inertia requires a lot of time to warm up the walls. The solution to the problem is to increase the thickness of the masonry or the use of thermal insulation. Insulation of the brick wall from the inside, made in compliance with the technology, will ensure a comfortable temperature in the house.

Vapor permeability requirements

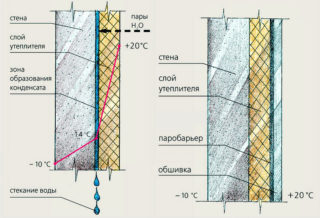

The technology of warming a brick house from the inside causes controversy among specialists. Many do not recommend using this method. The reason is the low vapor permeability of insulating materials and the appearance of moisture on the walls. According to building codes, the vapor permeability of materials should increase from the inside out. The possibility of water vapor penetrating through the walls allows you to get rid of moisture that accumulates in the room.

If problems arise in her abduction, dampness appears, mold and fungus grow. Microorganisms are dangerous to human health, they cause asthma, respiratory diseases. Moisture leads to the destruction of walls. To prevent negative factors, it is necessary to correctly choose materials for thermal insulation and comply with the technology of installation of insulation.

Features of internal insulation

Houses made of brick, aerated concrete, aerated concrete blocks or panel blocks are better insulated from the facade. But there are objective reasons why it is impossible to perform the procedure:

- a ban on changing the facade of a building;

- the room is bordered by a stairwell or elevator;

- insufficient funds to pay for services on the upper floors of a multi-storey building;

- a deformation seam is located on the structure.

The material for thermal insulation must meet the criteria of safety and environmental friendliness. During operation, toxic fumes that are harmful to human health are not allowed to be released. Another feature of the placement of materials from the inside of the room is the appearance of moisture on the walls. To prevent getting wet, choose insulation materials with minimal vapor permeability.

Insulation will be the basis for the finish. A durable surface will be provided by products in the plates - foam, expanded polystyrene, chipboard, warm plaster.

Advantages and disadvantages of the method

Before starting repairs, you must weigh the pros and cons of the method. If there are more positive moments, it is worth taking thermal insulation of brick walls from the inside.

Benefits:

- Heat does not escape through walls, heating costs are reduced.

- Obtaining permission to carry out repair work is not required.

- You can install the insulation yourself.

- Work is carried out at any time of the year, regardless of weather conditions.

Disadvantages of technology:

- Condensation on the building envelope.

- Reducing the usable area of the room.

- Increasing the moisture level in the room, requiring the creation of forced ventilation.

- Freezing and wetting of the external walls accelerates the processes of destruction.

When choosing the optimal material for thermal insulation, a significant role is given to the coefficient of thermal conductivity. The lower this indicator, the more efficiently heat is stored in the house. Also, such an insulator can be mounted with a layer of small thickness. It takes up less free space in the room.

Popular materials for warming a brick house

When deciding to install thermal insulation indoors, it is important to choose the right material. Traditionally, the problem of heat conservation is solved with the help of polystyrene, extruded polystyrene foam, and mineral wool. In addition to these materials, there are modern rolled and sprayed heaters. Which heat insulator to use the apartment owners decide individually. In many cases, the decisive factor is the cost of building materials.

Expanded polystyrene

Polyfoam is the most affordable, and therefore popular insulation. It is made by foaming polystyrene. Gas-filled cells provide low heat transfer and excellent soundproofing qualities. The material does not absorb moisture, resistant to biological effects. Polyfoam is easily cut, glued to the wall using a special solution. The lack of material is flammability. For safety, it is recommended to finish the insulation with a layer of plaster.

Penoplex

Extruded polystyrene foam (EPS) is characterized by high density, low thermal conductivity and vapor permeability. It is lightweight, does not absorb moisture. The material is available in the form of plates with a groove-ridge connection. They are easy to install, can be glued directly to the wall, without installing the frame. The advantages of the material are:

- small plate thickness - 40-50 mm;

- resistance to fungi and mold;

- long service life;

- resistance to compression.

When using EPSS, the installation of a vapor barrier membrane is not required. To create a tight coating that does not allow moisture to pass through, it is necessary to process all the joints between the plates with mounting foam. The cost of extruded polystyrene is higher than polystyrene. But the material has improved performance.

Mineral (basalt) wool

Mineral wool has good vapor permeability, which in the case of internal insulation is a minus. To prevent it from getting wet, it is necessary to cover the wall with a special waterproofing membrane or a plastic film. The material is used in plates and mats. The first option is preferable, cotton wool will not sag due to increased rigidity.

Basalt insulation is safe for health, does not burn, absorbs noise. The disadvantages of the material include the complexity of installation. It will require the creation of a multi-layer vapor-tight cake and installation using frame technology. The insulation needs finishing with drywall or OSB boards.

Penofol

Foamed polyethylene with a foil outer layer refers to roll insulation. It is not afraid of moisture and can be mounted without waterproofing. The foam base promotes thermal insulation, and the aluminum foil reflects infrared radiation. Thin material is rarely used alone. It serves as an excellent complement when installing mineral wool.

- Expanded polystyrene

- Penoplex

- Mineral wool

- Penofol

Modern methods of insulation

New heaters appeared on the construction market that have all the necessary properties for installation in an apartment.

Warm plaster

A universal mixture based on cement or gypsum has received heat-insulating properties due to the introduction of a porous filler. Plaster manufacturers use expanded clay, foamglass balls, perlite, vermiculite and polystyrene foam granules. Working with the mortar does not differ from the traditional process of plastering walls. The advantage of the method is the absence of cold bridges.Stucco has good adhesion to any type of surface.

Spray foam polyurethane (PUF)

The composition has low thermal conductivity, does not allow steam and moisture. It is securely fixed on a brick, concrete, wooden surface. A continuous layer avoids the effect of cold bridges. Spraying occurs by machine method, which reduces the time of repair work. The material is safe for health, approved for use in residential premises. Sealed coating is a thin layer, does not take up much space. The only drawback is the high cost of work and the need for special equipment.

Liquid ceramic insulation

Liquid insulation is still a novelty. The building material resembles acrylic paint, but it contains ceramic granules that reduce heat loss. It is applied directly to the wall in several layers with a brush or spray gun. The composition prevents the appearance of condensate, when applied there are no seams left. According to the performance characteristics, a layer 1.5 cm thick is equal to 50 mm of mineral wool.

- Liquid ceramic insulation

- Polyurethane foam

- Warm plaster

How to prevent condensation

Insulation of the walls inside the brick house leads to a shift in the dew point. Under normal conditions, it is located outside or in the middle of the supporting structure. After installing the insulation, warm air from the room collides with the cold wall, forming condensation on it. Permanent moisture will destroy the structure. It is especially fatal for silicate brick. Dampness becomes a fertile environment for the development of microorganisms. High humidity negatively affects the condition of the insulation. Mineral wool from wetting loses its performance.

There are several ways to avoid condensation problems:

- Before insulating the brick walls from the inside, install a hydro- and vapor barrier membrane for sealing. Mount the canvas with an overlap of 5 cm, glue the joints with tape.

- Use a heat insulator with a minimum vapor permeability index. The material will not leak moisture to the wall.

- Lay the insulation close to the building envelope, apply the adhesive in a continuous layer.

- To arrange high-quality ventilation in the room. Moisture removal will reduce the amount of vapor entering through the thermal insulation.

It is recommended to lay the insulation with access to the floor and ceiling in order to avoid the creation of cold bridges.

Necessary tools and materials

The popularity of expanded polystyrene when warming houses is explained by the low cost of the material, excellent insulating properties and ease of installation. To complete the work you will need:

- building level;

- roulette;

- stapler;

- hacksaw;

- screwdriver;

- putty knife.

It is necessary to prepare materials:

- foam boards with a density of 25-35 kg / cubic m, a thickness of 50-100 mm;

- adhesive mixture;

- polyurethane foam;

- fiberglass;

- plastic dowels.

To dilute the glue and plaster mortar, you will need buckets, as well as a mixer nozzle for a screwdriver.

Stages of wall insulation

Warming a house from a brick from the inside with polystyrene foam occurs in several stages:

- Cleaning and leveling walls.

- Surface treatment with penetrating primer. The composition will improve adhesion and protect against mold.

- An adhesive composition is applied to the foam boards. The material is pressed against the wall for a few seconds.

- All rows are stacked with a shift of half the sheet.

- For reliability, the plates are fixed with plastic dowels with fungi.

- The seams between the insulation are sealed with foam.

- After drying, fiberglass is applied to the surface of the polystyrene foam and plastering is performed.

As the finish of the walls using painting, wallpapering.

Insulation of brick houses from the inside is a justifiable measure to maintain a comfortable temperature with low heating costs. The main thing is to choose the right material and mount it according to the instructions.