For efficient heating, it is extremely important to choose the right stove, thanks to which the room will maintain the optimal temperature for receiving water procedures. One of the most sought-after companies engaged in the production of sauna stoves is the Varvara trademark. For more than 10 years, Varvara sauna stoves have been at the forefront of this industry.

Popular models of the Varvara furnace

The manufacturer has designed several different models of furnaces, each has its own characteristics and is adapted to specific working conditions.

Model "Terma-Tale"

The Varvara Fairytale sauna barbarian stove is the most popular model equipped with a closed heater, which is lined with talcum chloride stone. Thanks to this design feature, it is possible to obtain soft steam due to the heating of the stone to high temperatures.

Specifications:

- dimensions - 1120 * 500 * 800;

- wood firebox;

- weight - 245 kg;

- the length of the furnace is 0.76 m;

- stones can be put 60-70 kg;

- steam room volume - 12-24 cubic meters.

Recommended by the manufacturer, the cost of this model is 49 500 rubles.

Volzhanka model

The Volzhanka series sauna stove is used for large steam rooms. The tank is made of stainless steel. The main technical characteristics of the model:

- sizes - 1000 * 510 * 820;

- wood firebox;

- weight - 150 kg;

- the length of the furnace is 0.72 m;

- steam room volume - 24-35 cubic meters;

- stones can be put 60-80 kg.

The manufacturer's recommended cost is 24,700 rubles.

Model "Palenica"

This model for a bath is made of steel 6 mm wide, convection holes are located on the side. Power at "Palenica" is standard and is no more than 12 kW, weight 113 kg, the total weight of the stones to be laid should not exceed 50 kg. The average cost of a model without any options is 13,500 rubles.

If desired, you can purchase a model with advanced equipment. Its technical characteristics:

- Removal of a fire chamber to 30 cm.

- Equipped with a water heating circuit, the thickness of the stainless steel is 1 mm. It is built into the side walls, all connecting elements must be made of metal, plastic is prohibited.

- Equipped with a hinged tank, the tank capacity is not more than 55 liters. Fastens to a special pocket located sideways.

- Tank on the pipe for the pipeline with a capacity of 60 and 120 liters.

- Steel door 4 mm wide with panoramic glass.

Depending on the selected components, the cost of the unit varies.

General characteristics and design features

Stoves "Varvara" for a bath are characterized by simplicity of design. This is one of the main qualities that users love her for.

Stoves "Varvara" for a bath are characterized by simplicity of design. This is one of the main qualities that users love her for.

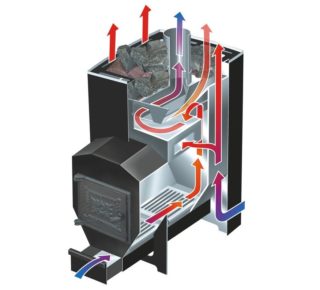

All bath stoves include the following components:

- a heating casing that transfers its own heat to the room;

- a firebox for burning wood - the heat of the main structure is transferred from here;

- chimney;

- the furnace chamber is located next to the furnace - here the final decay of the formed flue gases takes place;

- grate and ash pan.

The designers provided for the presence of an opening in the rear of the unit, which simplifies the process of cleaning the furnace from combustion products and soot. There are also models that are additionally equipped with a stainless steel water tank. The thickness of such a sheet is at least 1.5 mm.

The company "Barbara" presented 8 models of stoves for a bath. Despite such a limited selection, the thoughtful design meets all the requirements of the buyer:

- an oven equipped with a water tank that is installed on its side;

- standard equipment not equipped with heat exchanger and tank;

- modification of the previous furnace with a water heating circuit.

An integrated water heating circuit allows you to complete the furnace with a tank of up to 120 liters. As a rule, it is mounted at the top, acting as a connecting element between the ceiling and the hot pipe. Thanks to this, the user gets a double benefit - the pipe allows you to heat the liquid in the tank, which does not require the use of protective materials to isolate the pipe from the ceiling materials and the ceiling itself.

Another feature of the products is the possibility of using the furnace as a boiler as part of a water heating system. In most cases, the side tank has a capacity of up to 60 liters.

Advantages and disadvantages

The demand and prevalence of furnaces of this company is due to a large number of advantages:

- the possibility of retrofitting;

- in comparison with analogs acceptable cost;

- ease of use;

- low weight of structures;

- ease of installation;

- maintainability.

There are also disadvantages that you need to carefully read before buying.

- Installation of the stove involves its lining with finishing materials. Neglect of this requirement will adversely affect the thermophysical properties of the equipment.

- Slow heating of water in the tank.

- The design is equipped with a afterburner, which indicates a long combustion process. In turn, this leads to the formation and accumulation of condensate inside the chimney.

Each potential buyer will be able to choose the right model for their needs.

Barbarian stove with brickwork

Models of brick ovens have an attractive appearance. Advantages of units:

- Increased heat capacity of equipment. Bricks accumulate the received heat, and gradually give it away as it cools.

- The space in which such equipment is installed is filled with dry heat, such characteristics are typical of steam rooms only in Russian baths.

- A design that differs from analogues, especially if instead of using ordinary bricks, use decorative stone.

The main disadvantage of the modifications is the large weight of the brick, which, combined with the weight of the unit itself, forces the owner of the living space to build a new kiln foundation.

A common problem is the search for a conscientious furnace master who can perform all the work efficiently, using materials and compositions suitable for working with high temperatures. In most cases, use a mixture of sand and clay.