The efficiency of the chimney for a solid fuel boiler determines its performance, draft and safety for people living in the building. In the process of fuel combustion, smoke and soot is formed. These substances can cause clogging of the pipe and cause a fire when they accumulate in large quantities. The chimney for a solid fuel boiler must be strong, fireproof and durable. A prerequisite for achieving these criteria is the correct choice of material and compliance with the installation technology.

Types of chimneys for solid fuel boiler

Chimneys for the boiler TT can be made independently or purchased ready-to-install products. The choice is determined by the design features of the furnace and the building, their own abilities and financial capabilities.

Pipe material options for solid fuel boilers:

- Metal. Black iron structures are durable and affordable. Circular duct provides good traction. The downside is that the metal quickly rusts under the influence of the acid formed by the interaction of soot and condensate.

- Brick. It is the material checked by time, steady against the highest temperatures. It can be used for the construction of a chimney for a coal boiler. However, the brick quickly collapses from changes in moisture levels.

- Refractory glass. Such pipes are rightfully considered the best. They withstand high temperatures, do not react to acids, carbon deposits do not form on the inner walls. The only disadvantage is the high cost of production.

- Ceramic pipes. Chimneys are resistant to extreme heat and corrosion. Smooth walls do not collect soot, which contributes to the efficient operation of the boiler and increased safety.

- Asbestos-cement pipes. Products are inexpensive and easy to install. However, they do not withstand strong heating, can be installed in long-burning furnaces and in chimney sections where the temperature drops to 350 degrees.

- From stainless steel. Such pipes well tolerate intense heat, even from coal. Products are strong, reliable and durable. However, over time, they can become a victim of corrosion.

- Ceramic sleeve in the chimney

- Brick chimney

- Stainless steel and metal

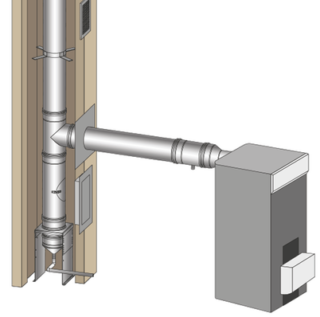

At the installation site, the chimneys are divided into internal and external types. The choice is determined by the design of the building and the power of the heating equipment.

Indicators when choosing a chimney

Manufacturers indicate recommendations for the diameter of the chimney pipe for the boiler in the documentation that comes with the product.

There are the following criteria by which the compliance of the device for the removal of flue gases and heating equipment is determined:

- Pipe height. The larger it is, the better the traction will be. But this will lead to increased wind load and an increase in the length of the plane of contact with the combustion products. The minimum value is the elevation of the slice 100 cm above the flat roof or 50 cm above the ridge of the gable roof.

- Section. The best option is a circle. Broken lines reduce traction, and carbon deposits are deposited in the corners, which contributes to the formation of caustic acids.

- Temperature threshold It should be 20-30% higher than the temperature produced by the selected fuel.The wood burns at 300 degrees, and coal can create heat reaching up to 900 degrees.

- Durability. This quality is determined by the resistance of the material to corrosion and its hygroscopicity.

- The internal area. Ideally, it should match the boiler nozzle. An increase in diameter leads to a decrease in traction, and a decrease makes it difficult to remove combustion products.

All of these requirements correspond to ceramic, glass and steel pipes made of stainless steel.

When conducting design and calculations, it is necessary to take into account the cost of materials and soberly assess their capabilities for their installation.

Basic installation rules

When constructing a chimney for a solid fuel boiler, it is recommended to adhere to a number of rules that will ensure the efficient operation of the heater.

The rules are as follows:

- Position the pipe at a safe distance from combustible surfaces and objects. If this is not possible, protect them with screens of materials with low thermal conductivity.

- Avoid the formation of straight and sharp corners on the route of the highway. Such places reduce traction, collect dirt and soot.

- If the height of the pipe exceeds 150 cm, it is necessary to make extensions to prevent it from tipping over or breaking by strong winds.

- It is necessary to install a condensate collector from the bottom of the first pipe compartment. This will avoid clogging with solid deposits.

- If the shape of the pipe does not match the configuration of the chimney, an adapter must be used. Coat the remaining slots with heat-resistant sealant.

The main requirement for the design is its fire safety and the absence of the risk of smoke in the room.

Chimney installation recommendations

The installation of the chimney must be carried out in a certain sequence, so that the structure is strong and stable.

This event consists of the following stages:

- Preparation of the base and installation of a solid fuel boiler.

- Marking for the manufacture of holes, fastening clamps and struts.

- Drilling holes in the wall or openings in the ceilings, depending on the chosen laying method.

- Sealing passages with heat-insulating plates with pre-made holes for the pipe.

- Assembly of the chimney. The technology is selected according to the selected material.

- Sealing the remaining cracks. Installation of condensate collector. Installing the cap on the upper cut of the pipe.

Checking the installation is carried out by kindling the hearth with newspapers or grass, with the control of all joints for smoke.

DIY chimney

The brick chimney for a solid fuel boiler is quite large, but this is not its drawback. The vertical structure has good heat capacity and can be used for additional heating of the room, the water circuit and heating the attic.

The construction is carried out in the following sequence:

- A solution is made from a mixture of sand and clay in a ratio of 3: 1.

- Preparing a solid burnt brick of red color, the quality of the stones is checked.

- The tower is laid out with a side of 2-2.5 bricks and a thickness of 1 brick. The thickness of the mortar is taken 1.5-2 cm. For 4 heights of the stone before overlapping, the masonry is suspended.

- A fluff is laid out to reduce draft and exhaust gas temperature. After the passage of the ceiling, the narrowing of the tower to a width of 1/8 stone in each row begins.

- The masonry is displayed through the roof, in this place another expansion (otter) is made, the total height of which is 6 rows.

- Making a deflector that prevents air swirls from entering the pipe.

In conclusion, heat and waterproofing work is carried out after which a control firebox is carried out.