In conditions where it is problematic to install bulky water radiators in the house, a film infrared heating system will help, which will provide a simpler and more comfortable heating mode. Many of us do not yet imagine what advantages electric film heating can have. The article before you will help you figure out how to turn the energy of electricity into thermal radiation and at the same time reduce financial costs.

How does infrared heating work

Heating a home with infrared (IR) radiation can be compared to the warming effect of ordinary sunlight. Rays of thermal energy penetrate the air and act directly on all surfaces of objects in the room, including the human body.

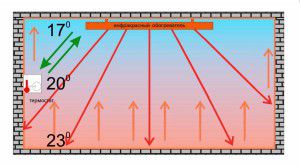

Absorbing the heat radiated by the film heating system, the walls, floor and furniture are warmed up, and then the temperature is transferred from them to the surrounding air. At the same time, it gets warmer on the floor, and near the ceiling the air is a little cooler. According to users of film infrared heating, in a room literally in a few minutes, normal conditions for life are created.

By heating the room with infrared film heating, it is possible to achieve a more uniform temperature distribution than from conventional radiators.

The device of infrared heaters

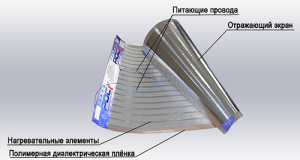

The heating element in the film infrared heating devices is a resistor made of a metal-graphite alloy, capable of transforming electricity into thermal radiation. It is laid in narrow stripes between two layers of polyester films. The aluminum foil covering the heating element contributes to a more uniform emission. The contacts for connecting to the mains are output to the outside.

This design is an autonomous heat-radiating circuit, which can be controlled using a temperature sensor and a control unit. After heating the room to a predetermined temperature, the power automatically turns off. The emitter itself is heated during operation to no more than 45-50 ° C.

Depending on the factory of the manufacturer of film heating systems, their sizes vary from 30 to 120 cm in width and from 1 to 5 meters in length. The weight of one film element is only 0.3-0.5 kg. Power consumption of IR heating films is in the range of 80–350 W. The most popular systems of film heating PLEN and Zebra.

It is useful to know that each of these infrared film heating systems can safely be left on for any length of time.

The factory of film heating systems "PSO" produces heating elements in a reinforced moisture-proof design. Thanks to additional protection and the ability to connect grounding, film heating Zebra is recommended for use in wet rooms. The mode of its operation in conditions of unstable voltage in the network has also been improved.

Benefits of heating with infrared radiation

Many positive reviews gained film infrared heating. And such recognition is well deserved, because the system has the advantages of:

- IR heating film system is easy to install and convenient to operate;

- higher efficiency in comparison with other heating systems;

- environmental and fire safety, no risk of carbon monoxide poisoning;

- the heat does not dissipate in vain, but heats home objects;

- You can heat either the whole room at once, or only the necessary areas;

- air circulation during the operation of IR devices is minimal, there are no drafts;

- oxygen in a heated room is not “burned”;

- the film heating of the PLEN is completely silent.

An additional convenience of the ceiling film infrared heating can be considered that this system is almost invisible in the house. It is easy to install on the ceiling and close with any finishing material that matches the style of the interior. Useful space is not reduced, which means that there are no restrictions on the way furniture and interior objects are arranged.

It is better to use film-based heating systems as not the main, but an additional way of heating the house, since their performance depends on the uninterrupted supply of electricity.

The calculation of the health of infrared heating

For an accurate calculation of the film infrared heating system, you will need information about the following parameters:

- the total area of the house and each room where the system is supposed to be installed;

- the number of window openings and their sizes;

- Method of thermal insulation of the foundation and walls;

- what electric power is allocated to the building.

If we talk about the approximate determination of the required power, we can take as a basis the statement that for heating a well-insulated outside of the house, 50 W / h for each meter of area heated by ceiling IR elements is enough. But this figure is averaged.

In fact, for warming a cold room to + 20 ° C, at the initial stage, a power of up to 180 W / hour per square meter is required. m. In the future, the automation will switch to the mode of maintaining a constant temperature and will consume no more than 15 W / hour. This once again demonstrates that it is not without reason that film heating is called electrosaving.

Ceiling heaters produced by plants of film heating systems, as a rule, have a power of 125 W and 150 W (per 1 m² of film surface). If we take the power of 150 W / m² for calculations, then with an average consumption of 50 W / hour, it turns out that 1 m² of a heat emitter can heat 3 m² of a room.

Although the ceiling-mounted version of infrared film heating consumes less electricity than floor-mounted infrared heaters, it is necessary that peak loads do not exceed the capacity of a home electrical network.

The table shows the permissible wiring loads:

| Wire material | Wire cross section (mm²) | Permissible load (A) |

| Copper | 1,5 | 12 |

| 2,5 | 20 | |

| Aluminum | 1,5 | 7,5 |

| 2,5 | 12,5 |

The method of mounting film heating

When infrared film heating is located on the ceiling, it shows the greatest efficiency. With this method of heating, the thermal rays are directed downward, and the air that has time to warm up rises to meet them. Film elements can cover about 50% of the entire surface of the ceiling, leaving room for the installation of fixtures. In this case, the space of the room will warm up evenly. But you can limit yourself to heating only certain zones, for example, in the area of external walls and windows. With local heating, energy costs will accordingly decrease.

The infrared heating system is quite easy to install, but this process is better timed to coincide with the overhaul of the room. The fact is that the elements of film heating PLEN are not installed on an unprepared ceiling.

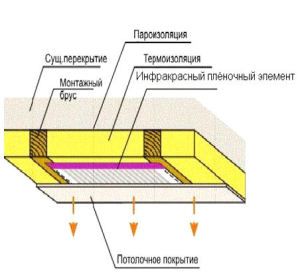

First, you have to do the preparatory work:

- lay vapor barrier on the ceiling surface;

- build a frame of longitudinal wooden beams;

- lay a heater between the rows of bars;

- it is desirable to cover the resulting “pie” with a heat-reflecting screen.

After that, you can proceed with the installation of the films themselves. The roll is gradually deployed and fastened along the edges with a stapler to the lower planes of the bars.

The film should be tightly, without voids pressed to the insulation layer. Subsequently, the external decorative cladding will also need to be pressed tightly to the surface of the film elements.

To install thermostats and connect the film elements to the network, you need to lay the wiring. For each room with infrared heating, you need one thermostat. It is mounted on a wall and supplied with power. It is recommended that the cable to the ceiling be packed in a corrugated hose and hidden under the wall cladding. The cross-section of the wiring should correspond to the design load, so a wire thickness of 1.5 mm² may not be enough, it is better to use a thicker 2.5 mm².

For safety reasons, it is prescribed to connect the Zebra film heating only on a separate line with a circuit breaker and ground.

Infrared heating recommendations

Practical tips are based on the feedback of those who already use infrared film heating:

- What to do if only 3 kW has been supplied to the house and the machine is periodically “knocked out”? Indeed, such power is enough only for 60 m² of area. At first it is possible to heat only residential premises, and subsequently change the wiring;

- If it seems to you that your ceiling film infrared heating is spending more electricity than promised, check your home with a thermal imager. Then it will be possible to detect the "sins" of poor insulation and take measures to reduce consumption;

- Leave the IR heating system in your country house on, even if you arrive there only on weekends in winter. Let the minimum temperature (10 degrees) be maintained in your absence. Expenses in general for the season will be less than if the system had to be periodically switched on to the maximum mode for heating a cooled house.

To summarize the aforesaid, we note that the system of electrically saving film heating, built on infrared elements of the PLEN, can indeed become an acceptable alternative for you to traditional types of heating.

The video clip will tell about the advantages and methods of installing the PLEN heating system: