A condensing gas boiler is a gas water heating device designed to provide heating and hot water to a home. The equipment is environmentally friendly, economical, reliable and safe with proper installation and correct operation.

Equipment specifications

The main details of the condensing boiler:

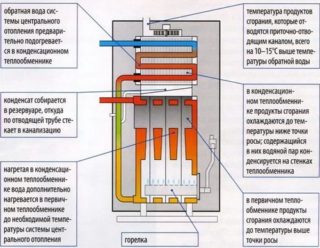

- A collection of condensing liquid that enters the structure after cooling the exhaust air.

- Heat exchanger. It is made of stainless steel or aluminum alloys with the addition of silicon, which are resistant to acids.

- Gas burner with a closed combustion chamber. The device allows you to automatically adjust the volume of gas supplied, air.

- Management and control system.

The efficiency of this equipment is 100%, which is an order of magnitude higher than that of generators operating on solid and liquid fuels.

Principle of operation

Condensing boiler is an improved version of conventional convection similar gas equipment. The essence of the work is quite simple:

- for operation, main or liquefied gas supplied in cylinders is used;

- in the process of fuel combustion, carbon dioxide and water appear, which leads to the production of a large amount of energy;

- the resulting heat heats the coolant, which is most often technical water;

- hot liquid of the right temperature circulates through the system, organizing heating.

According to experts, the conventional convection boiler has an average efficiency of 90%, and the remaining 10% goes into the pipe and heats the air on the street. To eliminate such losses, a condensing boiler was created.

The device, having worked out the main stage of fuel combustion and transferring heat to the heat exchanger, sends the resulting combustion products to the condenser, where the gaseous composition cools to 50-60 ° C - before the process of transition of water from vapor to liquid occurs. Such a transformation is also a source of additional useful energy.

Advantages and disadvantages

The main advantages of condensing gas heating boilers include:

- the minimum amount of waste due to complete combustion of fuel, which increases efficiency and positively affects the environment, reducing the emission of harmful substances by 7 times;

- profitability on average 35% + energy efficiency;

- low smoke temperature below 40 ° C, which allows you to install an inexpensive plastic chimney with pipes of the smallest section;

- compact size, light weight;

- low noise, vibration;

- ease of installation with the ability to use several boilers in one system;

- modulating burner;

- high power

- automation.

The main advantages include the fact that the equipment quickly pays for itself. A double-circuit condensing boiler also has some disadvantages:

- the need to provide a drainage system for condensate;

- obtaining permission for installation in the relevant services;

- strict observance of installation technology requirements.

The bureaucratic side of the procedure is as simple as possible. However, before installation, it will be necessary to perfectly align the walls, floor, assemble the chimney, observe the distance. All this is usual troubles when organizing gas heating and ensuring your own safety.

Selection rules

Condensing boiler is an economical heating with 100% efficiency, which will last for more than one decade. To make the right choice, you must consider the following factors when buying a device:

- Power. To select the right indicators, it is important to make certain calculations in advance, taking into account the height of the ceilings, the area of the building, the quality of insulation, especially the climate zone. Most often, equipment that is too powerful is not necessary, as this will increase costs and increase the wear rate of the mechanism.

- The number of circuits. Experts recommend purchasing dual-circuit structures for small houses with good thermal insulation. For more severe weather conditions, it is advisable to opt for a single-circuit boiler.

- Fuel consumption. This indicator directly depends on the power of the device, the expected load and the efficiency of the heating.

- Heat exchanger fabrication material. This criterion affects the reaction rate of the system to external factors. Aluminum alloy with silicon (silumin) resists aggressive environments well. Such a heat exchanger is almost always produced cast to reduce the development of corrosion. Stainless steel has increased anti-corrosion properties, low cost, resistance to thermal shock.

- Temperature modes of operation.

- Automation and variety of functionality. Modern boilers are controlled by sensors, electronics, which control fuel consumption, temperature, pressure. All this can be expanded with additional options.

- Installation methods: floor or wall.

- Price: premium, medium, economy class.

It is also important to pay attention to equipment dimensions, color and design.

Single-circuit and double-circuit

Gas condensing boilers are single and double circuit. In the first case, the mechanism has one coolant movement circuit and is intended only for heating. The second option is provided with two circuits of fluid circulation, which allows you to heat the room and organize hot water supply.

Advantages of single-circuit boilers:

- Great functionality that allows you to configure the operating modes of the device and gas flow.

- Automatic security system.

- The basic option for creating a variety of heating systems with a large number of wiring.

- Sensors of control, regulation of heating depending on changes in temperature on the streets and in the house.

- Clear, easy operation.

- Long service life.

Single-circuit type equipment has an affordable cost.

Advantages of a double-circuit boiler:

- Multifunctionality: the mechanism simultaneously performs the option of a heater and a boiler.

- The amount of heated water meets the needs of the user, there is no shortage and excess, as the liquid is constantly heated in the process of entering the tap.

- The compact size of the model allows you to install equipment in small rooms.

When choosing a single-circuit design, it is necessary to take into account that, if necessary, in hot water supply, it will be necessary to purchase additional equipment that can hit the budget and require additional space. The dual-circuit boiler also has disadvantages. It is important to constantly maintain a balance between heating and water flow, otherwise it will lead to unstable temperature readings and poor water supply with poor pressure.

In order not to incur fixed costs, you need to take power calculation seriously. If there is no need for large volumes of efficiency, you can buy a device simpler and cheaper. The main thing is that the boiler copes with the tasks assigned to it.

Before you buy equipment, you must coordinate with the appropriate authorities the installation process and make sure that such heating is allowed for the selected type of building and there are no prohibiting factors.