The issues of thermal insulation of residential buildings are always given increased attention. The industry has mastered the production of various types of protective materials that meet the requirements of current standards. Among them, a special place is occupied by modern formulations under the name “liquid thermal insulation”, it is advisable to familiarize themselves with the features of their application in more detail.

Varieties of liquid thermal insulation

On the domestic market there are several varieties of liquid insulation, which have a different basis and differ in application technology. The following materials belong to this category:

- liquid ceramic thermal insulation;

- expanded polystyrene or penoizol;

- sprayed ecowool.

Each of the listed liquid heat insulators is suitable for specific working conditions and has its own specifics.

When choosing this category of heaters for a residential building, it is important to understand that they are united by the possibility of mechanized application to protected surfaces.

The first of these varieties is presented on the market by a number of well-known positions, which include Aterm, Corundum and Armor. “Teploizol” and the special composition “Teplo Plus”, which managed to gain popularity, are ranked as the second type. When using these funds, it is possible to close large areas with a high speed.

- Liquid foam

- Ceramic insulation

- Ecowool

The possibility of high-speed spraying belongs to the advantages of this category of liquid thermal insulation. However, it should be remembered that for such work it will be necessary to invite professionals with special equipment, which significantly increases operating costs.

The sprayed ecowool for external and internal use is made on the basis of:

- typographical marriage remaining unused in the publication of magazines and books;

- corrugated or cardboard packaging waste;

- secondary raw materials (waste paper), which include newspapers, magazines, old books and the like.

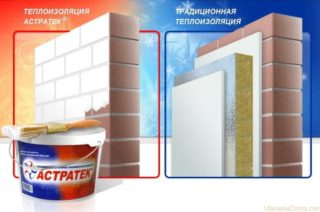

Liquid heaters have obvious advantages compared to sheet protective materials.

Advantages and disadvantages

The indisputable advantages of liquid thermal insulation coatings include:

The indisputable advantages of liquid thermal insulation coatings include:

- the possibility of applying to surfaces characterized by complex relief;

- resistance to climatic factors;

- high processing speed of protected surfaces;

- obtaining a monolithic coating that does not have unwanted joints.

The possibility of applying without changing the configuration of the facade of buildings eliminates the need to coordinate this procedure with the relevant supervisory authorities. The good adhesive properties of liquid insulators make it possible to do without thorough preparation of the surface for their spraying.

Among the shortcomings are the following technical difficulties:

- at the slightest violation of the rules of storage and transportation of the liquid mixture, premature loss of the declared qualities of the insulation is possible;

- relatively short service life in comparison with traditional insulation materials;

- the high cost of foamy heat insulators that cannot be applied without the involvement of builders and special equipment or mechanisms.

It is possible to minimize costs if you conduct a preliminary survey of the cultivated areas and choose the optimal application method.

Scope of use

The liquid state allows the use of heaters of this type during the following special operations:

- thermal insulation of walls and floors;

- insulation of ceilings and roof elements;

- protective treatment of highways and individual pipelines of various profiles, as well as steam pipelines and air channels in air conditioning systems;

- thermal insulation of window and doorways in the apartment;

- protection of freezing systems (here they are used for insulation of refrigerators, thermal boxes and trailers).

One of the most common applications for liquid coatings is the insulation of existing cold water supply lines. After processing with these materials, the likelihood of corrosion on metal pipes is sharply reduced.

Floor insulation

For insulation of floor coverings, ceramic thermal insulation, penoizol or liquid foam can be used. Some experts recommend the use of heaters for these purposes, which are called thermal paint. If desired, it is allowed to be applied to metal floor elements, previously painted with an even layer of ordinary dye.

For insulation of floor coverings, ceramic thermal insulation, penoizol or liquid foam can be used. Some experts recommend the use of heaters for these purposes, which are called thermal paint. If desired, it is allowed to be applied to metal floor elements, previously painted with an even layer of ordinary dye.

The choice of a specific brand of thermal insulation protection is determined by the type of flooring and its current state.

For walls and ceiling

Liquid insulation for walls is represented on the market by the following positions:

- polyurethane foam;

- penoizol;

- liquid mixture in compact containers.

To spray liquid thermal insulation to cover the walls from the inside and outside, special equipment is used that mixes the components of the polyurethane composition and then delivers it to the treated surfaces. Suitable materials and the method of applying insulation for the ceiling are similar.

How to choose a liquid insulation

Before choosing a particular type of coating thermal insulation, it is first of all important to determine the nature of the insulated surface. If it is required to insulate the internal elements of the building, a specially designed liquid material is selected (Astratek Universal or Akterm Standard). For processing surfaces located outside the building, special mixtures of the “Facade” type are traditionally used. Regardless of the place of use, it is advisable to consult with a specialist before buying and carefully study the instructions for use of insulation. It is also recommended to check its quality by external signs: consistency, color and the absence of impurities. The mixture "Magneterm", for example, must satisfy the following requirements:

- a high-quality product looks like a homogeneous mass, there are no clots and foreign fragments in it;

- the color of the vast majority of classic liquid heaters is milky white;

- the density is not very high, which can be verified by the weight of the container with the mixture (it is usually lighter than water).

If there are noticeable deviations in at least one of these signs, it is better to refuse this proposal and look for another option.

Application Features

To apply most types of liquid thermal insulation, you will not need special skills or expensive equipment. The exception is liquid foam and penoizol. For work, it is necessary to prepare the roller, which can be replaced with a brush or spray. When using a knurling tool, it will be necessary to prepare a container that allows you to evenly distribute the mixture on its working surface.

The process of applying insulation is reduced to the following sequence of actions:

- The treated surface is cleaned of dirt and excess solution, after which it is swept with a brush and washed with clean water.

- The purchased composition is diluted to the desired consistency (according to the instructions) and poured into a suitable container in volume.

- The roller is dipped into a container with the working mixture and rolled out on a special platform until the coating is completely saturated.

- Next, you should carefully roll the absorbed composition over the surface, without trying to put strong pressure on it.

The first layer of insulation is applied according to the "bottom-up" scheme. All subsequent roll after its complete "solidification" (polymerization), which occurs after about 24 hours.