Each technical room, especially the boiler room in a private house, requires the allocation of additional space. This must be taken into account, as it is often impossible to do without a heating boiler. It is important to study in advance the possibilities of using units of this type and observe a number of conditions when creating a boiler room project and installing all communications.

In what cases is a boiler room necessary

The territory of the boiler house is a place where, in addition to the boiler and related equipment, there are systems for water treatment, heating control, as well as hot water supply. A boiler room or boiler room in the house is necessary in cases when large floor-standing boilers are used for heating. The best option is to install a powerful chimney that helps eliminate combustion products and attracts the air flow necessary for the functioning of the boiler. The presence of a gas analyzer helps prevent gas leakage in time, so it is also advisable to install it additionally.

If the building area is more than 200 square meters, you definitely cannot do without a boiler room, since stationary equipment will be needed to supply heat to such a large room. Often in private homes, floor-standing boilers and fresh air ventilation systems are installed, for the heating of which air from the street is required. It is advisable to place such devices in the territories specially allocated for them inside the building, and not in an extension on the street.

The issue of placing a boiler room should be decided by specialists at the stage of building design. The type of project depends on the capacity of the boiler and the flow of hot water, the availability of special systems for water treatment and ventilation.

Requirements and Standards

Regardless of the room option, it is necessary to install units for heating and water heating in combination with additional communications strictly in accordance with the new requirements and standards for heat and water supply. The current rules are laid out on the portal of Rostekhnadzor, but it must be noted that the standards may differ depending on the type of boiler and fuel, for this reason they need to be updated. The walls of the boiler room are made of brick or concrete, the floor is mainly made of concrete, in the presence of a coating of metal sheets. During the repair, the walls and floor are tiled or the upper part is covered with non-combustible plaster.

The boilers should not fit snugly against the walls, for safety reasons there should be extra space around them. Even the smallest change in the design of the room must be consistent with current standards. The design of the ventilation system and the chimney is calculated according to the power and parameters of the unit, while in one room you can put no more than two devices. The front door must open strictly outward, it is made of materials of refractory type. All heating units and boiler units are placed taking into account the following requirements:

- the device can be placed in a separate room on any floor, including basements and basements;

- total power of the system cannot exceed 350 kW;

- installation of the unit requires placement of ventilation, the calculation of the system of which is carried out taking into account the area.

JV boiler plants with power below 150 kW are installed in rooms suitable for the operation of such units. The room must be fenced off from adjacent rooms with the help of reflective walls, equipped with high-quality hoods and a personal chimney.In the absence of ventilation, they leave space under the door and often ventilate the boiler room.

Minimum area

Area norms for gas boiler rooms must be observed at the stages of construction and use of the premises. If thermal installations with power up to 150 kW are installed in a separate territory, the volume and area of the room for them should be at least 15 m3 and designed depending on the service standards and the size of the main and additional devices. If the heating unit and the instantaneous water heater with a volume of not more than 60 kW are installed in the kitchen, its area should also be at least 15 m3 with 0.2 m3 per 1 kW of unit power.

Distance to facilities

In terms of size, the height of the ceilings in the boiler room should not be less than 2.5 m and 2 m, if the power of the units is less than 60 kW. Wall-mounted appliances are placed on walls made of non-combustible materials while maintaining a minimum distance of 2 cm from the wall. If the walls are made of combustible and non-combustible building materials with non-combustible insulation, the gap between the base and the boiler must be at least 3 cm. In the passageways, the space from the protruding parts of the equipment should not be less than a meter.

Types of boiler rooms

There are several options for creating home boiler plants, they are divided into types, taking into account the location of boiler rooms and varieties of boilers. Most often in large houses they organize separate rooms that are specially built for this purpose. Equipment is connected to the building using utilities, this is a good option for those who do not want to endure inconvenience if there is an aggregate located inside the building.

Annexes or attached boiler rooms are very popular due to their low cost, they are installed as tightly as possible to buildings. There is also a variant of the built-in type, it is more budgetary, but at the same time quite laborious in terms of design and development of the room layout. Laying communications in such a room should be as simple as possible, additionally take into account the cost of sound insulation, since some varieties of boilers are very noisy during operation.

Gas

Gas supply boilers are considered the safest and are intended for installation in settlements with a gas supply line. Gas boiler rooms do not cause difficulties during operation, since the process is fully automated. With their help, you can heat buildings with any area, they are also quite economical, because gas boilers give more energy than they consume. A modern appliance ignites automatically and is equipped with a system that stops operation in the event of an accident.

Such boilers have a service life of up to fifteen years and are environmentally friendly due to the minimum emission of harmful substances, the absence of soot and soot. The list of shortcomings of the gas boiler includes the mandatory installation of automation to prevent leaks and special requirements for rooms.

For gas equipment, you need to create chimneys and steam generators, check and clean all units annually. Their installation is permitted only after agreement with the specialists of Gaztekhnadzor.

Solid fuel

Rooms with solid fuel boilers can be equipped in any country houses in the absence of gas supply. In such units, energy sources are wood waste, for example, linden, firewood or coal. A solid fuel boiler room is a good budget option, since it is suitable for cheap fuel, including wood processing waste.It is also safe and environmentally friendly, it does not require electricity during operation, and the combustion coefficient is more than 80%, due to which ash and soot are practically not formed.

Devices of this type serve more than fifteen years without the need to change additional parts. They also have disadvantages, including the mandatory presence of a chimney with high draft when installing the boiler, as well as a separate room for the device. They need to be charged regularly and often cleaned as they become dirty. In addition to allocating a separate territory for the placement of a solid fuel boiler, you will need an additional place where you need to store firewood, coal or pallets.

Designing a technical room

The equipment of a boiler or boiler room in a private building as well as in an industrial building or at an enterprise requires compliance with the norms of SNiP in the revision of 2019, the versions of 2012 and 2017 are considered obsolete. First, the list of norms for creating a boiler house project in a private building should be taken into account. Units are installed taking into account the layout of the house in the basement, in the attic or in a separate room. If desired, it is permissible to use containers with mini-boiler houses, to build separate buildings or extensions. It is also possible to use a finished boiler room assembled from sandwich panels and finished with non-combustible materials. Primary requirements:

- compliance with the dimensions of the premises during construction;

- competent approach to door installation;

- constant access to all units;

- installation of a window with a window and sashes opening outwards;

- the presence of a chimney and ventilation;

Important! The wooden walls of the outbuildings or individual boiler rooms are finished with non-combustible building materials. For structures of any type, it is best to use concrete blocks or brick.

Project approval

The largest would be the cost of building a gas boiler, since such a project will have to be coordinated in several institutions and hire specialists to develop it. In addition to the project documents for approval, you need to provide a technical passport for the device, a conclusion of a sanitary-hygienic type, a certificate for the equipment, as well as instructions for its use.

Installation of equipment

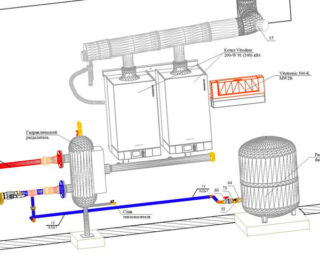

Mounting begins with the arrangement of equipment on a plan or diagram and the allocation of zones where heating, sewage, cold and hot water supply systems will be located. The next step is the installation of engineering systems of the house type, all the inputs into the boiler room are mounted depending on the location of the devices. The boilers are connected to the distribution manifolds and install additional units. The installation of all systems and elements should be handled by professionals with the appropriate permission, observing the norms of SNiP 89.13330 or 89.13330.2012 and recommendations from the instructions of Sidelkovsky, Yurenevy, Tretyak and Roddatis.

The arrangement of the boiler room

A boiler room or a boiler room is a room in which a large number of devices are installed with the aim of organizing hot water supply and heating. It should have the main boiler, boiler, distribution unit, accumulator and parts of the security system. The best choice would be a room with an area of at least 6 square meters, a maximum volume of 15 cubic meters, with a ceiling height of at least 2.5 m, walls and floor made of non-combustible substances.

When installing a boiler room in a private house, design standards must be observed. Only in this case, the system will work in uninterrupted mode and will not be at risk of possible accidents.