The simplest and cheapest way to organize hot water supply is a double-circuit boiler, which simultaneously provides room heating and water heating. Popular designs are products under the brand name "Ariston", Baksi ". These models attract customers and are in the top sales. Despite the simplicity of the mechanism and a large number of advantages, such equipment often fails. The boiler does not heat water for many reasons. Sometimes a little maintenance is enough to restore the device’s performance, and in some cases, an expensive overhaul is required.

Faulty heating boilers

Common boiler failures include:

- coolant leakage;

- water hammer;

- after turning on the burner, a lock is activated;

- the burner does not turn on;

- fuel burns unevenly, undulating;

- soot is formed;

- decrease in productivity;

- during operation of the burner, ignition is switched on;

- soot is formed on the walls of the chimney, combustion chamber.

To eliminate the malfunction, it is first necessary to establish the cause of the problem.

Built-in pump malfunction

An important detail in the heating system is the circulation pump. The quality of heating and the functioning of hot water supply depend on its uninterrupted operation. There are several signs and causes of breakdowns:

- The unit makes uncharacteristic sounds. This is due to the oxidation of the shaft, getting into the structure of a foreign object, with problems with the power supply, air in the pipes, the dry movement of the mechanism, the appearance of cavitation.

- After switching on the boiler, the pump does not start. There may be no power supply, a fuse has tripped.

- After a short period of time after switching on, the structure is switched off: limescale in the stator glass.

- The hot water does not turn on in the dual-circuit boiler.

Also, the reasons for the poor operation of the circulation pump are poor pressure in the system, wear of the bearing, which causes additional vibrations in the line, low pressure.

To troubleshoot, you need to check the availability of electricity, clean the pipes and other elements, replace the failed parts, and remove foreign objects from the system.

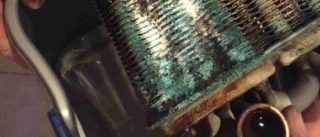

Heat exchanger clogged

Heated gases are transported through channels that are collectively referred to as a heat exchanger. Design features are that the walls of the artery simultaneously serve as partitions of the water circuit, along which the coolant constantly moves, heating the metal surface. The combustion process is associated with the intense emission of flue gases partially consisting of soot, tar, which build up plaque inside the boiler, in the chimney. Therefore, the manufacturer recommends regular cleaning of the equipment at least once every 30 days and during the preparation of the device for the heating season.

When soot settles on surfaces, the performance of the mechanism decreases, fuel consumption increases, and the risk of expensive breakdowns and internal fires in the area of pollution increases.

Three-way valve does not work

The part, depending on the model, plays the role of a flow separator, switch, mixer. Loss of operability of the device often leads to overheating, incorrect temperature of the coolant.

Causes:

- violation of the integrity of the electric drive;

- wear of the flow distribution mechanism;

- malfunction of the electromagnetic coil;

- the presence of condensate;

- power surge;

- stray currents;

- hit of a foreign body.

To diagnose and fix the problem, it is recommended to call gas workers with the appropriate qualifications. You can independently purge, release the resulting air plug. During the repair process, worn out seals, inoperative elements or the entire valve are replaced.

Heating circuit problems

Often the causes of a failure in the functionality of the trunk are failures in the wiring performance:

- clogged filter on the return;

- incorrect installation of the heating circuit;

- insufficient pump power.

All of the above problems are recommended to be eliminated during the preparation for the heating season, otherwise you will have to stop the operation of the unit and completely drain the coolant.

To eliminate clogging, the filter is cleaned, the circuit is washed, the coolant is completely replaced with a new one.

Lack of power is formed against the background of the presence of branches located remotely from the pump or with insufficient productivity of the device. As a result, equipment overheats, energy consumption increases, batteries do not heat up to the required temperature indicators or remain cold. In this case, there is only one way out - replacing the pump with a more powerful analogue.

If there are errors during the installation process - the wrong slope of the highway - it is recommended to redo the wiring, entrusting this matter to professionals.

Reasons for poor water heating

Gas boilers do not heat water for several reasons:

- blockage of heat transfer pipes;

- pump malfunction: jamming of the rotor, air lock;

- problems with the duct sensor;

- three-way valve breakage;

- insufficient pressure.

To eliminate the malfunction, it is necessary to find the cause and carry out a number of works corresponding to the problem:

- flush the system through the use of specialized compounds and install a filter at the coolant inlet to the boiler;

- remove all foreign particles that interfere with the functionality of the rotor or the water flow sensor;

- clean existing filter elements from contamination;

- clean the three-way valve and check the gas hose.

If the Baksi boiler does not heat hot water due to low pressure, it is recommended to check the pressure level, fittings and valves. In the absence of leaks and other technical troubles, it is necessary to add the coolant to the expansion tank.

Prevention and cleaning methods

Many gas boilers do not heat water, because preventive measures have not been taken in advance. Heating equipment requires timely maintenance:

- cleaning;

- replacement of components and worn parts, gaskets, seals;

- gas adjustment;

- pressure control.

It is also important to monitor the correct coolant level in the expansion tank.

If the Baksi boiler does not heat water due to contamination of the OS elements, it is necessary to carry out cleaning. There are several ways:

- Mechanical. It is produced with a scale thickness of 1 mm to 3 mm using equipment from a flexible shaft, with a drive and cones.

- Hydrodynamic. It occurs by flushing pipes with high pressure water.

- Chemical.For the event, specialized equipment and an aggressive surface composition are used.

- Electric discharge. The method allows you to remove contamination of increased strength. A working cable with a certain power / frequency of electric discharge is transported along the main filled with water.

The cleaning method is selected taking into account the type of boiler, the nature of the impurities and the thickness of the scale.