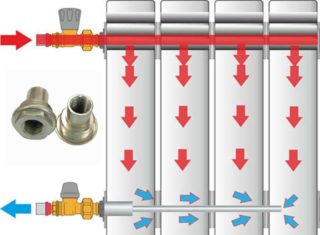

Radiator units with a large number of sections are often heated unevenly. Faced with this situation, you can install a heat transfer agent or take other measures. If, with no air plugs and proper connection, some battery cells remain cold, you can install a flow extension for the radiator.

Purpose of the stream extender

The part is used to change the flow direction of the thermal carrier, which allows the battery to heat evenly without reconnecting. The duct extender is suitable for radiators connected from one of the sides. Often it is installed on the reverse connection, due to which the water moves diagonally.

Typically, the part is used for long batteries (the number of cells is more than 10), since their design contributes to uneven heating. The farther the section is from the tube through which the water is supplied, the greater the likelihood that it will remain cold. The easiest way to fix this is to install an extension cord. This will help to make the circulation uniform and efficient. The device is suitable for bimetal batteries (with aluminum and steel components). For cast iron structures, it is rarely used.

Pros and cons of using

The main advantages of the device are ease of installation and increased efficiency of the heating system. To purchase it or do it yourself do not require serious financial investments. To install the device, it is enough to have basic locksmith skills. Productivity gains are achieved without adjustments to the existing battery connection diagram.

The duct extension for a bimetallic radiator has certain limitations for use. You can put it only on radiators connected one-sidedly from the right or left side. They should also be equipped with shutoff reinforcing elements from the return and water supply side. If this is not the case, fitting will fail. You will have to contact the master and reconnect, which requires a lot of labor.

Ready-made extension cords are rarely found in stores, but they are not difficult to make yourself or order online.

Extension cable features

The main components of a flow extension for a heating radiator are a small fitting (0.5 or 0.75 inches) and a pipe connected to it. The latter can be made of different materials - stainless steel, copper, polyethylene or metal. Copper tubes cannot be used in conjunction with aluminum radiators and parts: during the interaction of these metals are oxidized. The part mounted on the reverse connection changes the direction of movement of the coolant so that maximum efficiency is achieved. Such a method will be effective for long radiators (0.8 m or more).

DIY extension cord

It is not difficult to make such a design yourself if you have all the required accessories and a suitable type of battery connection. The cranes through which the radiator is connected must be spherical and equipped with American ones. They need to be blocked and drained. Then you can start installation work.

Procedure:

- On one of the sides is the upper foot.It must be unscrewed together with the detachable mount element mounted there. This must be done carefully so as not to damage the paint coating. Then it is advisable to replace the kruglyasha from silicone. You can dismantle the heating battery completely, if it seems more convenient for operation.

- Proceed directly to the assembly of the extension structure. The tube cut by a special tool will need to be soldered to the sleeve. First, it is cleaned from the inside from plaque and dirt by means of a ruff. Solder oil is a good flux. With a small brush it is applied on top of the part having a smaller diameter. Then one element is inserted into another and wipe off excess fat. The junction begins to heat the burner until a silver tint occurs.

- After that, solder is applied to it. If the heating is carried out correctly, the solder softens from high temperature, flows into the docking area and fills the space. When this happens, you need to wait at least a minute until the molten metal finally solidifies.

- An American with cleaned inner walls has a diameter of 1.9 cm. It is slightly larger at the coupling. You can use a small file to remove excess. This must be done carefully so as not to damage the parts. For clogging, you can use wooden gaskets.

- Sometimes you have to experiment with the tube length. Sometimes the length to the middle of the radiator is optimal, but it is preferable to start with a larger one. If necessary, the excess length can be cut off later.

The extension device is mounted in the hole and screwed. You also need to put in place the gasket and the battery itself. To remove air masses from the system, a Mayevsky crane is used.

Necessary tools and materials

It is necessary to choose a pipe segment that will perform the extension function. The thickness of its walls should be at least 1 mm, and a cross section of 1.8 cm. The length is taken approximately equal to the length of the heating battery itself. If necessary, it can be shortened in the future. It is important not to forget about the ban on the installation of copper elements in one design with aluminum (including with bimetallic radiators with parts from this metal). Ignoring this rule is fraught with the destruction of all reacting parts of the system.

For installation, you will also need to prepare the following parts and tools:

- Straight soldering sleeve with an outer diameter of 2 cm.

- Pipe cutter that allows you to evenly cut a piece of the extension cord of the required length without deformation of the metal. When working with this tool, the workpiece is held at a right angle. When cropping is completed, you can remove any irregularities with a brush.

- Fascinator. With its help, the burrs are eliminated in adjacent to the ends of the pipe section.

- Brush made of metal and a stiff brush.

- Device for expanding pipes.

- Solder.

- Soldering torch. A simple device of small dimensions will do, it can be charged with gas used for lighters.

The silicone gasket installed in the connection should also be replaced with a fresh one.

Popular manufacturers

Valtec bimetal battery extension cords are well known. This Russian-Italian company produces products for uniform heating of multi-section radiators. Fittings are made of brass and nickel plated. They have an external thread of 1 inch and a pipe designed for connection with a pipe of 1.6 or 1.8 mm. The catalog has small-sized options in 0.5 and 0.75 inches. Parts are manufactured with right-handed and left-handed threads.

The domestic company Rifar mainly produces sectional radiators from bimetal and aluminum. Suitable battery extensions are available for different battery models. Most of them have a size of 0.75 inches.

Elongation of the flow will be an excellent solution in a situation where the convector sections remote from the supply remain unheated. The device has a low price and is easy to do at home. Suitable for sectional radiators with a length of more than 0.8 m and connected from the right or left side. When buying or self-manufacturing, you need to pay attention to the compatibility of parts made of different metals.