Electrolux heating systems comfortably heat various rooms and optimally distribute surface temperatures. The electroflux heated floor can be laid without concrete screed, the mats are installed in a layer of tile adhesive. The system is used when it is not possible to raise the floor level by 5 - 6 cm.

Advantages and disadvantages of underfloor heating Electrolux

Mats work economically, cables with a special screen are laid at the base, so that they can be used safely in wet rooms, nurseries or bedrooms. The systems have high power and are used as the only heating option.

Advantages of floor heating Electrolux:

- comfortable surface temperature and uniform heat distribution over the area;

- heating occurs by the method of thermal radiation (from particle to particle), and not by convection, which is only 7 - 10% of the radiation;

- lack of dust and electromagnetic radiation;

- vertical heat transfer and minimization of heat loss through floors and walls;

- optimization of work with the help of automatic regulators.

Less of the sexes is recognized as an increase in electricity costs. The house requires replacing the old wiring before installing the heating mats, because increased load can lead to an accident. Underfloor heating is an expensive system and requires certain costs for materials and installation.

The flooring is selected with good thermal conductivity. For example, carpeting will reduce efficiency to nothing. Wooden floors dry up, for varnished coatings the optimum temperature is chosen not higher than + 21 ° С.

Wide range of products

The system raises the floor level only by 1-1.2 cm; it can be used on separate surface areas.

The product range includes products:

- heating mats;

- cable segments;

- temperature regulators.

Electricity is supplied using a thermostat that controls the intensity of the transferred heat.

Heating mats

Products are made on the basis of fabric with adhesive impregnation. The composition improves the adhesion of the mat to the lower and upper surface. Glue prevents the appearance of air bubbles and splits in the screed. The heating wire is woven into the base of textile and a homogeneous design is obtained. The fabric gasket does not deform during transportation or long-term storage, and the mat adheres tightly to the surface without protrusions.

Popular products are represented by:

- Eco Mat EEM.

- Multi Size EMSM.

- Easy Fix EEFM.

- ETC.

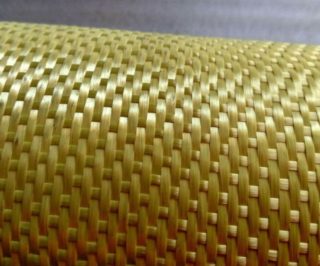

The heating wires have a teflon coating with Kevlar thread, which protects them from mechanical damage. The use of aramid cores allows you to stretch and bend the mats if necessary.

The specific power of the mat is not less than 105 - 115 W / m2 in the case of installing elements for additional heating. The indicator rises to a value of 125 - 150 W / m2, if the system is the only option for heating in the house.

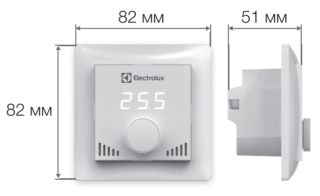

Temperature controllers

Effective work will become impossible without the use of the Electrolux floor heating controller. Devices of this brand are combined with underfloor heating from other manufacturers, so they are in demand. Automation makes the operation of the heating system rational.

In the design of the device there are devices:

- measuring sensor;

- temperature coordinator.

Models are distinguished by informative monitors, an easy way to adjust, some devices are equipped with touch screens.

Electrolux Termotronic Basic - thermostat Electrolux for underfloor heating is versatile, controlled mechanically. The power of the device is 5 W; it provides a temperature range from + 5 ° С to + 40 ° С.

Termotronic Avantgarde is an electronic device that allows you to set the temperature for a day. The device is equipped with an LCD monitor, consumes 2 W of power, heats the floor from + 5 ° C to + 50 ° C. Coordinates the surface temperature of the floor and air.

Termotronic Touch refers to thermostats based on electronics, allows programming of six heating modes for a day ahead and a week. Power - 2 W, temperature from + 5 ° С to + 90 ° С.

Heating sections

Heating segments are a novelty in heating systems. They differ from previous generations of electrical systems in that they are not subject to mechanical damage. These are sections that change size and can be stretched to 35% of the total length. Heating blocks easily fit in areas of non-standard geometric shapes, for example, triangular, diamond-shaped, semicircular.

Economical sections require less consumables during installation, which simplifies the installation procedure. After stretching, the power is distributed in proportion to the density. Solid sections heat up more than stretched ones.

The section includes tinned copper wires that are wound on an aramid core. The cable structure is coated with PTFE insulation. Protective layers increase efficiency, provide safety and durability. Factory tests showed the durability of the sections in the region of 50 years.

General characteristics

A two-wire or a single-wire wire is used in the design, warm floors work from a network with a voltage of 220 - 230 V and 50 Hz. The armored cable is equipped with a sleeve and a cold end on one side, and the end cap is placed on the other. A single-core wire is implanted into the base with two cold ends and sleeves, which adds to the difficulty of installation.

The choice of model is based on the type of flooring. According to the instructions, you can lay the heating cable under the tiled floor, made of natural stone, granite. The use of a laminate, linoleum without an insulating layer is allowed. Electrolux floors are installed in rooms with high humidity, but systems are used in which waterproofing is relied on by manufacturing technology.

Design features of floor heating Electrolux

Aramid fibers are a synthetic material of high strength against shock and temperature changes. Aramid are not current conductors, they melt when the temperature reaches + 500 ° C. The material increases the tensile strength, bending and tearing.

Fluoroplastic insulation is a reliable dielectric, characterized by electrical resistance and low wear. The material does not react to the action of aggressive components at room temperature, weakly passes gases, dies when ignited, resists local overheating. In cables of products of this brand, the second insulation of heating cores is used.

It turns out 3 protective shells:

- individual - for heating cores;

- waist layer;

- outer capsule.

The second shell eliminates cracks in the first layer and increases the resistance. The outer capsule is resistant to the components of concrete and tile adhesive.

Installation Rules

The wiring is checked, for this the capacities of all existing electrical appliances are added up, the load in the future is taken into account. It is recommended to connect the floors to draw a separate line from the shield and put the machine.

Work order:

- An installation diagram is drawn up. A gap of 40 - 50 cm is provided for walls, heating risers, radiators.

- The surface is being prepared. The putty is leveled by the area, primed. If there is an expansion joint on the floor, the mats are laid so that the mats with cables do not cross it.

- On the surface, the places of installation of components, technological joints are marked. Do not use extension cables or splices.

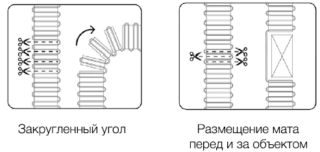

- The size of the mats is adjusted according to the scheme. Only the frame can be cut, but the wire cannot. The gap between the heating wires is at least 50 cm.

- A niche for a temperature regulator and a groove for supply wires are made in the wall.

- A temperature sensor is installed in the corrugated pipe, heating mats are finally laid out according to the scheme.

Installation is carried out at disconnected voltage. After installing the elements, the operability is checked by turning on the electricity.

Popular models Electrolux

Electrolux EMSM 2-150-1.5 kit. It is placed under different coatings, the base is stretched to 35% of the total length. Easy to fit in areas with complex configurations. Heating cables have 3 degrees of protection.

Set of mats Electrolux EEFM 2-150-3.5. The system is mounted without screed, only glue is used. It is connected to concrete with a self-adhesive coating. Aramid core of increased strength is used, which leads to an increase in cable resistance to damage.

Heating kit Electrolux EEM 2-150-7. The system involves one-way docking, which simplifies installation according to the scheme. A good quality fabric base helps to organize proper laying in different conditions.

Cable floor kit Electrolux ETC 2-17-800. The system heats up quickly and has a long service life. Wire heaters are stacked and mounted in rooms of different geometries.

Set of film infrared floor Electrolux ETS 220-7. It is placed under different coatings and redistributes heat throughout the year. It is placed without the use of wet materials (glue and mortar). Do not work in rooms with high humidity.