The vast majority of apartment buildings in our country have central heating. Housing and utilities reform, annually rising tariffs make people think about the efficiency of heat use. To reduce operating costs, you need to know the design of the heat supply system.

How is a centralized heating system

Central heating is a method of supplying heat from a single source to residential and industrial premises located on a large territory.

The general scheme looks like this:

- The coolant is heated at separate facilities to the required temperature.

- Through pipes laid in the ground or in an open way, heat is supplied to the houses.

- In the heating units, a metering of the spent energy and heat distribution along the entrances of the house is organized.

- On the risers of the house wiring, the hot coolant is supplied to each apartment and to the staircases.

- To heat the apartments, heat exchangers are used, which are commonly used as radiators or batteries.

The boiler room located in the house itself is a special case of central heating.

Each of the systems can be arranged in various ways and perform additional functions.

Heat sources

The coolant is heated in specially built for this purpose heat and power plants (TPPs), state district power plants (TPPs) or boiler houses serving several residential areas.

The names of thermal power plants and state district power stations remained from the Soviet era, although the owners now have private energy companies.

TPPs, state district power stations and boiler rooms differ:

- main purpose and mode of operation;

- power;

- radius of the served territory.

Based on economic feasibility, CHP plants are built in settlements with a population of 100 thousand people and developed industry. State District Power Plants are designed for small and medium-sized cities with low electricity consumption. Boiler houses heat residential and public buildings, production facilities within a radius of no more than 3 km.

Cogeneration plants are designed so that in the cold season their main purpose is to heat water for heating purposes. In the inter-furnace period, the station enters the power generation mode.

State-owned power plants are needed to generate electricity. Heat is released during the operation of the turbines and sent to the heating target.

Boiler houses exclusively heat water for heating systems; they do not generate electricity.

Heat Generation Scheme

The functional schemes of the TPP and TPP are very similar, the difference lies in the capacity and construction of the equipment.

The generation of electric and thermal energy at thermal power plants and state district power stations occurs due to fuel combustion. To work, you need coal, fuel oil or natural gas.

TPP device

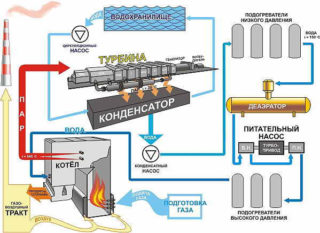

The main nodes of the CHP are:

- fuel economy - a set of fuel storage and preparation facilities;

- boiler room as part of the boiler and auxiliary equipment;

- turbine and electrical equipment;

- condensate installation;

- heat exchangers that remove heat for district heating;

- technical water supply system.

Additional are smoke removal and smoke cleaning systems, ash and slag removal systems, pipelines.

Boiler rooms are arranged much simpler - they do not include turbines, condensing units, or other auxiliary equipment.

The algorithm of the heat sources

Thermal power plants and state district power plants are extremely complex structures, but the principle of work on heating the coolant is not difficult to understand:

- Prepared fuel is supplied to the boiler room. Coal must be grinded, preferably to a state of dust. For combustion, air is supplied to the combustion chamber by pumps.

- In the boiler room, process water in the boilers is brought to a state of steam, which is under high pressure.

- Through pipelines, steam is fed to the blades of a turbine, which, rotating, generates electrical energy.

- After the turbine, the cooled steam enters the heat exchanger, where it gives off thermal energy to water for a centralized heat supply system.

- The cooled steam passes into the liquid phase, which the condensate unit cleans of vapors and impurities.

- The purified water is supplied to the boiler room, where a new heating cycle begins.

In the summer use mode, when much less hot water is required, the CHPPs are switched to the mode of generating electricity. In this case, the steam is cooled in the cooling towers to the state of water, it is pumped to a height of 12 meters and sprayed with special plants. Excess steam is vented to the atmosphere.

Water enters the pool where it cools. Then it is fed to the boiler room by condensing units. The process is repeated. To compensate for losses, water is added from external sources - rivers or lakes.

Coal-fired thermal power plants and state district power plants are necessarily equipped with smoke cleaning systems.

Heat exchanger design

The task of the heat exchangers is to take the heat from the steam passing through the turbine.

Devices are classified by design:

- shell-and-tube;

- sectional (elemental);

- lamellar.

Each of the species has many designs.

The most common and effective is the shell-and-tube version of the device. Steam under pressure enters the tube bundle, which is located in a sealed enclosure. Inside the case, chilled water is supplied. The process of heat exchange occurs - steam-heated tubes heat the water inside the tank. Pumps create pressure for the movement of fluid in the pipelines of the central heating system.

Features of district boiler rooms

Boiler rooms, depending on the intermediate coolant, are divided into steam and water.

In the first case, water is brought to a state of steam, in the second - water below 100 degrees is involved in heat transfer. The option depends on the project, the distance to the objects, and other technical features of the construction.

Steam as a coolant for supplying apartments is used less often, it can only be found in an old housing stock.

Home heating equipment

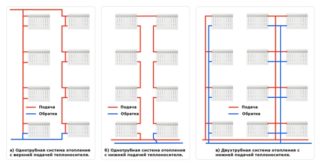

Heat distribution on the premises of an apartment building is carried out according to one of the schemes:

- single pipe with top filling;

- monotube with lower bottling;

- two-pipe with lower bottling;

- two-pipe with top filling.

In the first case, the coolant under pressure rises along the central riser to the upper floor. Then, by gravity, the water, having given part of the heat to the batteries, returns to the heat center and is then transported to the side of the thermal power plant (boiler room).

The risers pass inside the apartments and it is technically difficult and sometimes impossible to disconnect your home from the general system. The temperature of the radiators can be controlled by special thermostats, the installation of which requires welding work. In high-rise buildings, for the supply of coolant to the top floor, additional pumps are installed in the heat supply nodes, which increases the costs and cost of the services rendered.

Intervention in the work of the second scheme is also technically impossible - pipes here also pass inside the apartments.

Recently, in new houses and during the reconstruction of old buildings, two-pipe schemes have been implemented with the arrangement of general communications in the entrances or technological mines. In such cases, it becomes possible to disconnect a single apartment from the heat supply.

Unauthorized to turn off the heating for any reason, Russian law categorically prohibits.

There is a restriction on the installation of radiators in apartment buildings. Pressure in a 5-storey building ranges from 2 to 4 Atm, and in a 9-storey building up to 7 Atm.

In the summer, after repair work is carried out on the communications, a pressure test is carried out - the pressure is raised to 10-12 Atm in order to detect leaks. When the system is filled with coolant, water hammering is possible.

Based on the possible loads, when replacing radiators, they reject all-aluminum products, choosing bimetallic radiators. Pay attention to the guaranteed pressure levels that the battery can withstand.

Advantages and disadvantages of district heating

Advantages and disadvantages are inherent in any equipment, technical systems and communications. The pros and cons are considered in conjunction with the economic component and ease of use.

The positive qualities of district heating include:

- Current costs in the central system are comparable or lower than the cost of energy purchased individually.

- Most TPPs, state district power plants, and district boiler houses operate on any type of fuel, which makes it possible to create emergency reserves for work.

- Of the heating equipment in the premises are only radiators. Boiler installations are removed from residential areas, sanitary zones are installed around them, which improves the environment.

- The owner does not purchase expensive equipment (boilers).

- Heating of the apartment does not depend on the supply of energy and electricity to the house.

- The probability of accidents and disasters associated with gas leaks is reduced.

- There is no need to conclude contracts and pay for the maintenance of gas equipment.

- Accidents are eliminated by the supplying organization as soon as possible at their own expense.

The disadvantages are:

- losses in the networks that deliver heat to the house - the length of the pipeline can be 10 km;

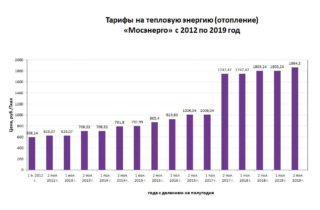

- the supplying organization lays down possible expenses in tariffs, therefore the payment is significantly higher than it could be;

- limited temperature control in the apartment, caused by schemes for building house networks;

- the impossibility of disconnecting a separate apartment from the house network without a court decision;

- dependence on tariffs (set by regional commissions), which the homeowner is not able to influence.

The most important disadvantage in ease of use is the inability to heat the house during the inter-furnace period. In spring and autumn, sudden changes in temperature are frequent, to which the CHPP cannot promptly respond. Changing operating modes entails large financial losses.

How to heat homes in other countries

Our country got central heating as a legacy of a socialist economy. Under the conditions of a planned economy and with large energy resources, central heating was built and for the most part paid by the state.

Pipes with coolant cooled in the houses on the way to the CHPP were a source of heat for greenhouses, industrial enterprises, and cattle-breeding complexes.

Mass production of equipment for individual heating systematically began in the mid-90s, before that there was a shortage even for private households.

There are very few countries on the planet with similar climatic conditions and a comparable population density. To save resources in much of the world, heating is decentralized.

In Germany, France, Canada, similar to our systems were built until the 50s of the last century. The ensuing global energy crisis has caused the development of heating systems that service one or more multi-story buildings. To do this, build a separate boiler room. There are no long lines for transporting hot water - losses are minimized.

Installations are easy to put into operation with a sudden cooling, and on warm days to reduce energy consumption by reducing the temperature of the circulating water.

There is no central heating in France and the UK - each apartment has a separate boiler with a closed combustion chamber, which is controlled by the landlord.

An important role is played by the availability and accessibility of energy in the region.

In Poland and China, a lot of housing is heated by coal, in Iceland - by hot spring water. Norway actively uses cheap electricity.

Ways to reduce costs

There are few opportunities to reduce operating costs for the supplier and heating costs for apartment owners:

- high-quality thermal insulation of trunk pipelines, especially those located on the surface;

- installation of common house meters for energy consumption, which compare the temperature of the coolant at the inlet and outlet - knowing the volume of the flowing liquid, the equipment automatically calculates the calories consumed;

- installation of individual metering devices in each apartment, which is applicable only for 3 and 4 schemes considered above.

There are no other options to affect payment.

Should central heating be abandoned

The legislation does not establish restrictions on changing the scheme, but there is no clear instruction yet on which to refuse heating in an apartment building.

The supplying organizations are directly interested in a larger number of customers, therefore, they agree on changes to the heating scheme only by court order.

The norm that only houses with a height of 11 floors can be gasified was recently canceled.

The court will need to collect documents, some of which are very difficult and sometimes impossible to obtain:

- certificate of ownership - redevelopment of non-privatized apartments is excluded;

- consent of the residents of the whole entrance - you can not get it only if the pipelines are not the property of the whole house;

- refurbishment project;

- gas service permit;

- coordination of the project with the Ministry of Emergencies or another organization responsible for the fire safety of the facility;

- hydraulic engineering calculation of a specialized organization about the possibility of re-equipping the system and preserving the characteristics after excluding a specific apartment from the general circuit.

You cannot completely refuse to pay. The receipt will leave the amount for the heat provided by the risers and deckchairs of the pipelines, you will have to pay fees for heating the entrance.

Central heating, which is not always economical, but reliable and universally used, can, under certain conditions and additional costs, be replaced by an individual one. Before starting the arrangement of personal heating, you should weigh all the pros and cons, calculate the costs and possible savings, and then make the final decision on the conversion.