The cellar is intended for long-term storage of vegetables and fruits, preservation, juices and dairy products. If there is sufficient free space, this structure, unlike the basement, is located separately from residential buildings. For the storage of food stocks, special conditions must be created. High and low temperatures lead to their rapid deterioration. Therefore, it is necessary to insulate the walls of a concrete grounded cellar. This process is simple enough to do it yourself without the involvement of professionals.

Why you need to insulate the cellar

The storage facility is being built at a distance from buildings equipped with heating appliances and utilities. This means that there is less external influence on the inner space and it is characterized by relative stability. Nevertheless, temperature differences in the winter and summer time of the year reach serious values, which cannot but affect the microclimate of the underground warehouse. Sometimes construction is carried out under sheds and garages in cooperatives. These buildings do not have any effect on the underground premises, but protect them from precipitation.

Basement insulation is carried out for the following reasons:

- In the summer heat, the earth is so hot that the heat penetrates deep underground, heating the walls of the cellar and its contents. From this, vegetables sprout, conservation explodes, pickles become moldy.

- In cold, snowless winters, the soil freezes strongly. It also affects the microclimate in the underground storage. Vegetables and fruits deteriorate, banks crack, after thawing smoked meats quickly disappear.

- When temperature drops, condensation forms. Dampness contributes to the development of pathogens, metal corrosion and the destruction of wooden products.

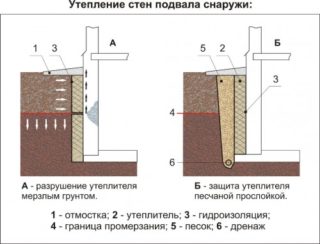

- From contact with the soil there is a gradual destruction of the walls of the structure. Insulation of the cellar from the outside protects it from exposure to an acidic environment and the development of a resource for freezing and thawing material.

Thermal insulation is selected so that it can last for more than a dozen years. This is especially true for materials that are planned to be used for outdoor installation. Carrying out their replacement involves a large expenditure of time and labor.

What material to choose

The basement level is constantly exposed to lateral and vertical pressure, dampness, acids, insects and rodents. These factors must be considered when choosing a heater. On sale is a wide range of materials that differ in price, performance and installation features. When making a choice, each property of the product should be evaluated.

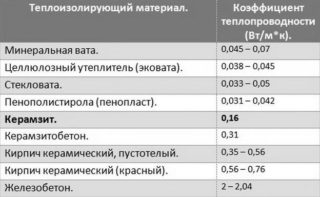

Expanded clay

Expanded clay is balls or sharp porous granules obtained by vulcanization of natural clay. The material is more often used when arranging roofs in residential buildings and outbuildings.

Products have the following advantages:

- affordable cost;

- low density;

- ease of handling;

- environmental Safety;

- low thermal conductivity.

Expanded clay is used less and less, since it has a limited service life due to shrinkage and hygroscopicity.

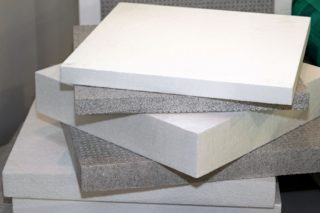

Styrofoam

Polyfoam is a time-tested material that is used in private and industrial construction, in preparation for the winter of summer and garage cooperatives.

Expanded polystyrene has such advantages:

- excellent insulating properties;

- water tightness;

- low specific gravity;

- ease of processing and installation;

- low price.

Among the disadvantages include fragility and toxicity during combustion.

Penoplex

The decision to insulate the basement with foam at the inside will create high-quality and reliable protection of the room from moisture, temperature changes, insects and rodents.

Polymer material has such advantages:

- dense structure, excluding crumbling and breaking during installation;

- low thermal conductivity;

- almost zero hygroscopicity;

- long term of operation;

- ecological cleanliness;

- repelling effect on living things;

- wide temperature range;

- resistance to alkalis and acids.

The disadvantage of foam is its high price, corresponding to a high-quality insulator. But, the invested funds are fully justified by the comfortable conditions in the cellar.

Minvata

Industry produces mineral wool from glass combat, steelmaking slag and natural stone. Finished products are randomly bonded in space fibers. Minvata is available in the form of mats and rolls, the thickness of which is 100-400 mm.

Advantages of the material:

- ease;

- low thermal conductivity;

- elasticity;

- flexibility;

- durability.

The disadvantage is its hygroscopicity and the release of many harmful volatile particles during installation.

Preparatory work

Preparation for insulation of the cellar consists of the following steps:

- Designing, calculating the needs of building materials and tools.

- Removing communications, cleaning surfaces from fragile fragments, clearing and sealing gaps.

- Alignment of walls and ceilings with cement mortar with the addition of plasticizers.

- Treatment of structures with an antiseptic and a primer.

To work it was more comfortable and safer, a layer of sawdust and sand should be poured on the ground around the cellar. To protect your hands you need to use fabric gloves.

Indoor or outdoor insulation

Experts recommend approaching the issue of thermal insulation comprehensively, finishing the cellar from the inside and from the side of the street. Each of the methods has its pros and cons, which should not be neglected.

Experts recommend approaching the issue of thermal insulation comprehensively, finishing the cellar from the inside and from the side of the street. Each of the methods has its pros and cons, which should not be neglected.

External insulation allows you to protect the supporting structures of the structure from moisture and temperature changes. Due to this, they further maintain strength and integrity. At the same time, there is no need to save space, since extra centimeters do not play a big role in the scale of the plot area. Exterior finish takes over the pressure of the soil, preventing deformation of the walls and base.

The decision to insulate the cellar from inside from freezing is made in those cases when, for any reason, it is not possible to do this from the outside. When choosing the type of insulation, it is necessary to give preference to environmentally friendly materials with the absence of smell and the release of small particles into the air. To neutralize the influence of dampness, you will need to sacrifice the internal space. It is necessary to install a thick layer of insulation, which must be resistant to dampness and fungus.

To prevent the development of mold, bleach should be crushed into fine dust and added to the primer, which will be used for surface treatment. This is a good way to disinfect support structures.

How to warm a cellar

Thermal insulation of the cellar is best done at the stage of its construction. This will avoid time-consuming work in the future when the need arises.It is advisable to do this from top to bottom, performing one stage after another.

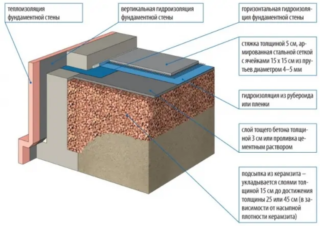

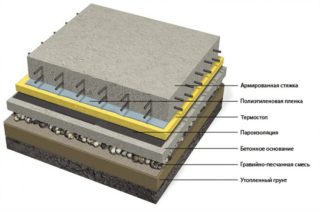

Base

Production of the floor is carried out in the following sequence:

- A depreciation and warming pillow is poured into the pit. The mixture is made of sand, gravel and expanded clay.

- Dense cellophane or ruberoid is placed on top of the pillow. The edges of the insulation are rigidly fixed in the ground with stakes.

- A layer of foam or foam is laid. The edges of the plates are glued with tape.

- Going to the frame of the reinforcement. Above the insulation, it rises by 15-20 mm.

- Concrete mortar is mixed and poured into the mold. It takes at least a week to solidify.

- When the base is fully strengthened, it is treated with a primer and antiseptic.

The final step is to lay the topcoat. The best option is wooden boards impregnated with linseed oil.

Walls

The walls have the largest area of contact with the ground and bear the bulk of the heat insulation of the cellar.

Their arrangement is carried out in this way:

- Removal of unstable fragments, expansion of cracks, their sealing with sealant or cement mortar.

- Surface treatment with a deep penetration primer.

- Installation of insulation plates. It can be polystyrene foam, polystyrene foam or polyurethane foam. The latter option is good because it does not require additional decoration.

- Application of a waterproofing layer. For this, ruberoid is best suited, characterized by strength and durability.

For interior decoration it is better to use materials of small thickness. A good solution is foil foam. Thin insulation effectively protects the room from moisture and temperature changes.

Ceiling

The ceiling of the cellar is closer than the rest of the structures to the surface of the earth, through which moisture, heat and cold act on the flat top of the structure.

The sequence of work is as follows:

- Processing the plate with an antiseptic and a primer. Laying hard insulation (at least 10 cm).

- The material is closed with a mounting grid or reinforcing grill.

- Concrete mortar is being poured.

- After the screed hardens, it is hermetically sealed with a layer of roofing material.

Plants with spreading roots should be planted above the cellar. They will strengthen the soil and create a shadow from the sun.

The correct approach to arranging the ventilation of the cellar will allow it to maintain the optimum temperature and humidity at any time of the year. To create an effective supply and exhaust system, you need to make vents in the lower part of the wall and in the ceiling. Plastic pipes are supplied to the holes, which are recommended to be pre-insulated. The air circulation will occur due to the difference in atmospheric pressure due to the difference in the height of the pipes.