Rod heat-insulated floor can be mounted under a tiled floor covering or under a coupler. From the point of view of the organization of space, this system is a good opportunity to rearrange furniture (there is no risk of damaging thin elements, as when using film options). Depending on the season and climatic conditions, it can be used for local heating or as main heating.

The principle of operation of the core heat-insulated floor

The main components of the design are carbon rods mounted on a special mat. As in the case of film systems, the operation of an infrared rod heated floor is based on the interaction of elements with electric current. In the process, heat waves are released. Passing through the flooring, they are transferred to the bodies of the inhabitants of the house and furniture.

As in the case of other heated floors, working on electricity, when installing the core system, it is necessary to install a temperature sensor and a temperature control unit. The design can work without these devices, but they provide self-regulation and help save power. To warm up a square meter of area, it will take 20-160 watts, depending on the number and density of carbon elements.

Structure and properties

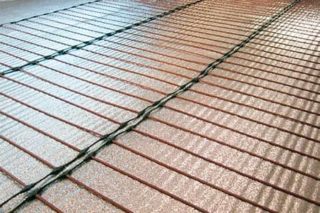

The basis of the design is composed of rod-shaped elements, in which, in addition to carbon, copper and silver are also contained. They are interconnected by cable, which is very flexible. When connected to the network, the rods are connected in parallel. The passage of electric current through carbon is accompanied by intense heat. One of the features of the system is the dependence of the amount of released energy on temperature. When the floor is heated, less heat is generated.

Equipped with a temperature control system, it allows you to control the consumed power indicator and save finances on heating. The regulation of intensity in this case occurs naturally. Constant work at the same power accelerates the wear of the warm floor.

Advantages and disadvantages

The core floor has good performance in terms of fire safety. Thanks to self-regulation, the surface is not exposed to overheating. Mat with rods tolerates heating up to 60 degrees Celsius. Other advantages of these floors:

- reduction of energy consumption in the heating season - a side effect of self-regulation;

- the ability to operate with different types of external coatings - tiles, laminate flooring, linoleum;

- environmental friendliness of the components included in the design, as well as the absence of electromagnetic rays, as a result - safety for the inhabitants of the home;

- detachment to the layout of the room, the ability to install under heavy cabinets and other pieces of furniture without harm to the mat and rods;

- resistance to moisture, which allows the use of the floor in the bathroom, and damage to the corrosion type;

- ease of installation for a person with basic building skills;

- lightness, which eliminates the overload of floors.

However, the design has disadvantages. This includes a high price and zero mobility: a mat laid under the flooring cannot be moved anywhere without first removing it. In addition, it is forbidden to combine a warm floor with foil insulation materials.Reacting with the aluminum contained in the foil, the alkali creates conditions for damage to the core components.

If water gets into the coating, the heating temporarily stops. It resumes after the moisture dries.

Sometimes attributing to the core floor the ability to saturate the air with ions. This is a publicity stunt without physical background. The rods are insulated from air masses with tiles or other coatings. Flooring cannot ionize air even when heated.

DIY core floor laying

The laying procedure itself is simple, but takes a lot of time and consists of a large number of stages. First you need to choose the place where the heating controller will be located. A temperature sensor and wires from the mats themselves will be brought to it. The location should be convenient for the owner of the home. You can place the control next to the light switch. When installing in rooms with moist air, the device will have to be installed outside the serviced room.

It is necessary to prepare a plan for the placement of heating elements. In each of the premises, there are areas where it is not planned to put the rods. For the remaining zones, a drawing is made showing the position of the elements. The interval to each wall should be at least 0.2 m. The rods should not cross or touch each other. Most manufacturers of cloths have a width of 0.83 m.

The rolled up mat is placed on the floor and begin to roll out. Upon reaching the site requiring a reversal, the wiring between the rods is cut with a knife. Having turned the mat 180 °, it continues to be rolled out in a different area. This continues until the floors are completely covered. The joints are glued with scotch tape. With its help, they create a clutch with a heater.

Having spread and strengthening the mats on the floor and making sure that the bonding strength is sufficient, they begin to assemble the electrical circuit. To do this, use a building hair dryer. They heat the pipe from heat-shrinkable material, into which they put the connector. Then another tubular element is mounted and heated until a high-quality clutch crimp is achieved. Similarly, the wiring diagram is collected to the end. Conductors that could not be used must be insulated. For this, handpieces supplied as part of the system are used.

When the circuit is ready, mount the temperature sensor. To simplify dismantling and replacing it, it is better to place it in a corrugated hose. For discreet installation in the screed, a recess is made. The hose body is placed in it and a temperature sensor is inserted. Conductors must be routed to the temperature controller and connected to suitable sockets. Now you can supply power. With a lack of skills in this area, it is better to use the help of a master electrician.

Before laying the flooring, it is necessary to conduct a trial inclusion and make sure that the installation is correct.

Tile laying

Decorative ceramic tile is a popular choice among finishing materials for core floors. The calculation of the coating is carried out according to traditional technology, but with the observance of specific points. Adhesive for work can be purchased only specially designed for underfloor heating. The total thickness of the tile and adhesive layer must be at least 20 mm.

Floor operation is permissible only after the mixture has completely dried. This should happen naturally. It is impossible to artificially heat the floor to speed up the process - this is fraught with an incident of short circuit, as well as a violation of the integrity of the screed.

Manufacturers Overview

Carbon core systems are mainly manufactured by companies from South Korea.One of the popular products is Starke from DYS Tech, a manufacturer specializing in different types of floor heating. There are floors from the GT-mat and Hotmat brands on the Russian market.

Unimat carbon floors are the most common in Russia. Two main products are positioned. The nominal power consumption of the Boost system will be 133 W for each running meter. In the Rail version, it is lower - 113 watts.

The core floors with carbon elements are attractive environmental friendliness and lack of reference to the layout of the room. They are compatible with many types of flooring.