Gas-fired boilers have long been the main heating equipment in multi-storey buildings and in small buildings. There are different types of these devices. Installation of a gas boiler is fraught with some difficulties: it is necessary to comply with the requirements for the room, the heating system, the availability of permission from utilities. If you can connect the device yourself, then experts must commission and service it.

Varieties of gas boilers

The classification of heating devices is carried out according to several parameters. At the installation site, they are:

- Wall mounted. Most models include a heat exchanger, control unit, burner, circulation pump, expansion tank, liquid temperature and pressure gauges in the system, and a safety unit. The advantage of the mounted boiler is ease of installation, low weight, no need for a separate room or boiler room equipment. You can hang it even in the kitchen. Often such a model is installed in an apartment. The power of the devices is limited.

- Outdoor. They have different dimensions and weight. Such devices are intended for heating large areas, since their power is greater than that of mounted options. Often floor models require the arrangement of a separate room or boiler room. The boiler control system is intuitive, although it is equipped with automation. Often, such devices depend on the electrical network.

In terms of functionality, the units are single-circuit and double-circuit. The first option performs a single function - heating the room. Double-circuit also provide hot water. However, at the same time, these functions are not performed. If you want to turn on the water heating, the heating is turned off for this time.

The functionality of double-circuit boilers can be increased by connecting additional modules. They are often used in apartment buildings. There are also parapet gas boilers. They are designed for heating and heating water. This type of apparatus is equipped with a closed combustion chamber, so the combustion products do not enter the room, oxygen is not burned.

The parapet boiler is equipped with a coaxial chimney, so there is no need to install bulky structures. In the body of the unit there are convection openings. The device itself heats the room in which it is installed.

Units with a closed and open combustion chamber are distinguished. For the first type of device to work, air from the environment is required, therefore special requirements are imposed on the ventilation of the room. Devices with a closed combustion chamber are safer, but a chimney is required for their operation.

Rules for installing gas boilers in a private house

Before installing a gas boiler, you need to consider its location, the features of connecting to the heating system, and also obtain the permission of the gas service. Since the specified unit is a source of danger, it must be mounted in compliance with the requirements of the state standard.

Boiler location

According to the standards, the area of the room in which the device will be installed must be at least 4 sq.m. The height of the ceilings is 2.5 m or more. The minimum width of the door in the room is 80 cm.

The room must have a window opening. On 10 sq.m. area required 0.3 sq.m. window.

Many models of gas-fired heating units must receive a natural oxygen supply, so good ventilation is provided in the room. There must be a distance of at least 10 cm from the boiler to the nearest walls. They must be protected by refractory material.

Premises in which the installation of gas heating equipment is prohibited:

- bases are not protected by refractory materials;

- hallway, bathroom;

- rooms without windows and windows;

- basements of multi-story buildings.

It is forbidden to mount heating equipment on balconies.

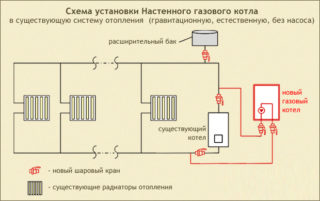

Installation diagram

For the installation of gas heating requires preliminary preparation of the project, as well as the choice of installation and piping of the boiler. The system contains such elements: the heating unit itself, pipes and radiators, a circulation pump, filters on the inlet pipes. Mandatory is the security unit.

DN15 taps are mounted on gas fittings. Larger diameter products are mounted on nozzles with a coolant. Filters at the inlet from the water supply are installed in a horizontal position. The expansion tank, if it is not included in the boiler design, is mounted using additional fittings and is attached to the return pipe. The drain pipe is located at the lowest point of the heating system.

Requirements for the installation of gas units

The room in which the gas boiler will be installed must have good ventilation. For every 1 kW of device power, 8 sq.cm is allocated. air duct width. It should be mounted at the top of the room. In addition, the following requirements must be observed:

- All pipes through which the fuel will pass are made only of metal.

- The diameter of the chimney depends on the power of the device. The minimum parameter is 10 cm. Part of the structure, which is located above the roof of the building, rises at least half a meter.

- To prevent negative consequences in the event of a gas leak in the room, an analyzer and a valve are installed to shut off the fuel supply. A meter is also required to control gas flow.

- If the private house has only 1 floor, the installation of equipment is allowed in the basement. In multi-apartment and multi-story buildings, such installation is strictly prohibited.

- The device must be earthed, the boiler power supply system is carefully insulated.

If the device is installed on a wooden base, a refractory plate is placed under it: metal, asbestos or basalt cardboard. The location of the wall-mounted boiler is also strictly determined by sanitary rules and technical standards: the distance to the ceiling is 45 cm, to the floor - 30 cm, on the sides - 20 cm. The minimum indent is 1 m to the opposite partition. If the device is mounted in a wooden room, between it and the back wall is laid refractory material, the thickness of which is 3 cm.

Channels for the removal of combustion products can be located inside the main walls. The chimney must be built of non-combustible materials that are not susceptible to corrosion. The design provides for a technical hatch for cleaning the walls of soot, eliminating the accumulated condensate. It is impossible that the pipe for exhausting smoke should be larger than the chimney itself.

Preparation for installation

Before installing a gas boiler in a private house, you need to prepare for work. The procedure consists of the following steps:

- Signing a contract with a fuel supplier.

- Creation of the project and coordination of technical conditions for installation and operation of the heating system with the gas service.For this, a technical passport of equipment, a sanitary-hygienic certificate, instructions for using the device, an expert opinion, which says that the device meets all technical standards, are provided to the body.

- Preparing a place to install the device.

It is also necessary to collect all the necessary materials and tools.

DIY installation technology

It is better to entrust the installation to gas service specialists, but if necessary, you can do it yourself. It is important to strictly follow the installation instructions for different types of boilers.

Floor boiler

Before mounting floor gas boilers, you need to check their equipment. On the surface of the device should not be dents, chips. The technical characteristics indicated on the device case must match the data specified in the data sheet.

Work execution order:

- Removing the plugs from the boiler and cleaning the pipes of litter that got there at the production stage.

- Installing the unit on a prepared foundation or foundation. Its level can be set using adjustable legs or non-combustible elements.

- Connection to the chimney. Holes for the arrangement of the structure should already be prepared. Corrugated materials must not be used to connect the boiler to the chimney. The areas of overlap and roof that will be in contact with the structure must be insulated with refractory materials. At the junction of the pipe and elbows, clamps are installed.

- Connection to the heating circuit and water supply. First, heating pipes are installed, on which coarse filters are installed. Shut-off valves are mounted on them. All connections are tightly sealed. In the same way the water supply is connected. If the liquid is very hard, you will have to put in equipment to soften it. To seal the joints, do not use rubber seals, as they quickly crack and begin to let gas through.

- Connection to power supply. It is better to equip the outlet at a minimum distance from the unit. If the model is unstable to voltage surges, a stabilizer or uninterruptible system must be used in the system.

After installation, gas service specialists check the system and carry out a test run. The coolant is pumped into the system gradually to prevent the formation of air jams. The procedure is carried out until a suitable pressure is reached - 2 atm. All connections are checked for water or gas leaks.

Wall boiler

To hang the wall unit correctly, you need to mark the base. Also checked the equipment. Brackets and mounting accessories must be supplied with the boiler. All pipes and pipes of the heating system are flushed. This procedure is necessary to eliminate industrial litter.

The base on which the unit is mounted must be perfectly flat. It must also withstand the weight of the boiler. Fixing strips are fixed at a distance of 0.8-1.6 m from the floor. Before connecting the product to the heating system, the plugs must be removed, the supply pipes should be equipped with a filter, on both sides of which ball valves are mounted.

During installation, make sure that the unit level is maintained. Even minimal skew will not allow you to connect it to the pipes, and also violate the functionality of the system. Gas pipes are connected only with metal elements through a drive or "American". The connection must be hard. You should not use any rubber gaskets or seals here - the elements should be paronite.

Parapet boiler

If you have the appropriate inventory and materials, you can install the parapet boiler yourself.However, for commissioning, a gas service officer is needed. Particular attention should be paid to the connection of the heating system and gas pipes, as well as to the output of the coaxial chimney.

A channel is being prepared for removing the air duct and chimney outside the premises. It must fit the pipe. The diameter of the outer ring is taken as the basis. It is better to place the chimney near the window. Such localization will allow you to clean the device and check its condition.

The first duct pipe is mounted. So that the part does not move, it must be fixed in the channel. After that, the water supply is connected to the boiler. Studs are installed with which the device will be held in a predetermined position. Nuts are used for fastening.

A chimney pipe is installed. It is tightly connected to the pipe. The part is installed with a slight slope so that condensate can drain. All gaps must be adjusted so that the flame in the burner is even. Lastly, a heating system with radiators is connected, an expansion tank is installed.

Correct installation of the boiler in the heating system will help to avoid problems with the depressurization of the connections, gas leakage, excessive fuel consumption. The procedure can be carried out independently if the standards and installation requirements are observed. However, it is better to invite a specialist who has access to such types of work.