Gas equipment for organizing heating is more popular than solid and liquid fuel boilers. This is due to ease of use and economical maintenance. Gas boiler houses are equipped with both private and apartment buildings. It is most advantageous to install this type of equipment if a gas main passes near the house.

Requirements before designing a gas boiler

Gas boilers have several advantages:

- high level of efficiency;

- minimum level of emissions of toxic harmful substances into the air;

- full autonomy in work.

When installing equipment on gas, owners may encounter problems, since such boiler rooms are subject to increased safety requirements. All of them are spelled out in documents fixing the norms for gas supply and equipment.

The heating boiler in a private house must be installed in a special room. In accordance with the safety requirements, it is forbidden to equip for furnace bathrooms. If a separate room is allocated for gas equipment, you must first familiarize yourself with the requirements of SNiP, which were approved in 2016. They fix the conditions that must be ensured when installing a solid fuel or gas boiler, as well as any auxiliary equipment for organizing the heating system of the house.

Special requirements for boiler rooms in a private house are presented due to the fact that this is an object of increased fire hazard. All approved standards provide for the implementation of measures that are aimed at ensuring the reliability and safety of premises, the prevention of accidents due to gas leaks.

The furnace room must meet the following requirements:

- ceiling height should be at least 2 meters 20 cm;

- the area of the premises should be at least 6 square meters;

- the boiler room must have a window; the glazing area in the boiler room with a gas boiler must be at least 0.5 square meters;

- under the door you need to make a hole that will provide fresh air.

The equipment must be provided with free access. There are no special requirements for the perimeter of the room. It is important that the width of the aisles is taken into account. A distance of one meter must be left from the boiler to the opposite wall.

Natural gas equipment can be installed on any floor in the house.

Standards and rules when calculating the window area

There are certain requirements for the window in the boiler room of a private house. The design must comply with all fire safety standards of a residential building. In accordance with the norms of SNiP adopted in 2017, the window opening should be calculated in the ratio of 0.03 square meters per one cubic meter of the room.

The air flow must pass through a hole from the street at least 150 * 200 mm. To reduce the amount of heat loss, it is necessary to make insulation of the lintel above the window, as well as to warm the window slopes from the street with the help of foam.

The norms of SNiP indicate that a gas boiler can only be installed in a room with a window. It should be equipped with any ventilation device. The window in the furnace should be considered not only as a source of lighting, but also as the most important element of ventilation.

The calculated area of 0.03 per square meter should not be the window itself, but glass.It, in turn, is an enclosing, easy-to-erase structure. If these conditions are not met, gas services will not be allowed to start the boiler room.

The term “enclosing easy-to-erase structure” means a building element that should be easily destroyed to relieve excess pressure. In connection with this function of constructions, reinforced glass is not suitable for them. They are characterized by strength, so the glass will not collapse under the action of the load. Relief pressure does not occur.

Cannot be used in boiler rooms:

- stalinite;

- polycarbonate;

- triplex.

According to GOST standards, it is permissible that ordinary glass can be replaced with window elements:

- with a rotary structure, which consists of a flap of an easily ejected type - during a gas explosion it should open outward and rotate around the hinges under the influence of excessive pressure;

- with a movable part, which consists of a frame with a double-glazed window - during a gas explosion, the structure collapses under the influence of pressure and falls out.

The pivoting sash on the window structure may be vertical or horizontal. Thanks to the variety of options, the functionality of the window is enhanced.

An important condition for windows in the gas boiler room is the presence of safety locking elements, latches and destructible parts of the fasteners. Their task is to ensure that when excessive pressure occurs, the movable or pivoting window mechanism is unobstructed.

Glazing material

When equipping a room for a gas boiler, it is important to pay attention to the material from which it is made. Designs can be made of aluminum or metal plastic. Materials are considered practical and resistant to high temperature effects.

Aluminum

The aluminum profile will protect the structure from all weather conditions. It will provide good sealing. Even with a strong gust of wind, the fire in the boiler will not go out. This eliminates the occurrence of a fire hazard.

Plastic

Safety requirements do not prohibit the installation of metal-plastic structures in the boiler room. The double-glazed window can be single-chamber and two-chamber. This will help keep you warm.

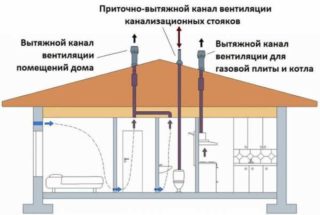

Ventilation

Particular requirements are made when equipping a boiler room with a ventilation system. The following requirements must be considered:

- A ventilation duct with a diameter of 110 mm is installed in the room.

- Access to air should be provided through openings in the door or floor, the supply openings are made in an amount of at least 8 square centimeters per 1 kW of gas equipment power.

- The ventilation must be insulated, make the pipe slope towards the street.

- To make a chimney, a channel breaks through the wall. It must be insulated.

- Combustion products must not enter living rooms.

- The chimney from the heating boiler must be higher than the ridge of the roof.

- The boiler can be installed on the floor or hung on the wall, but the main thing is that it is located at a distance from any electrical appliances

In the process of equipping the boiler room, it is necessary to provide that the boiler is provided with free access from all sides.

Additional communications

The room intended for the boiler room must be equipped with the necessary communications:

- Electricity, individual wiring closed. Mains voltage must be constantly stable. All wiring is laid in metal pipes. This is one of the most important guidelines.

- When choosing a device for lighting, it must be borne in mind that it must be explosion-proof. It is recommended to mount it in a sealed cover.

- All switches are installed from the street.

Ventilation must not be connected to the chimney.Otherwise, combustion products will enter the house.

Well-known manufacturers

Many companies are involved in the production of window structures. The most famous are:

- KBE is a manufacturer that produces optimal options for rooms where gas equipment is installed.

- Novotex Termo - the windows of this company are suitable for warehouses, hangars, workshops and boiler rooms.

- Rehau GENEO - a variant of aluminum glazing with a single-chamber double-glazed window.

It is important to know what window should be in the gas boiler, as non-compliance with the requirements will lead to large losses. The whole process of gasification of private houses is under the control of special services. Violation of the rules can lead not only to large fines, but also to an emergency.