A home brick oven is a traditional heating product that still attracts the attention of private homeowners. They are especially in demand in places where interruptions in the supply of gas and electricity occur. In regions rich in reserves of business forest and where there are no problems with firewood, the presence of a brick stove allows you to save on energy.

Variety of designs

According to their purpose, brick stoves for the house are divided into the following types:

- cooking products;

- cooking and heating;

- stoves used for heating living spaces.

A brick cooking stove for the house is optimally suited for a summer residence, for example, where the owners live in the summer. Sometimes it is used as an addition to other types of heating and allows you to save on expensive fuel. Its design contains a hob, built-in oven, and in some cases a reservoir for heating drinking water. Despite the relatively small size, its capacity is enough to heat a medium-sized room.

Brick stoves for a house of the second type may have:

- hob;

- built-in oven;

- a tank in which water is heated;

- place for drying.

They are also used as a fireplace or water circuit. This design remains in demand even in the presence of a gas boiler.

Purely heating brick stoves are used exclusively for heating interior spaces. Often they have several tanks that can be used as a fireplace in a bathhouse or for quick heating of water. When choosing, it is also important to determine the configuration and dimensions of the furnace, which affect the selection of its installation location.

Place selection

The oven can be placed in any suitable place, but the most convenient option is to be built into the wall between two adjacent rooms. Thanks to such placement in buildings of a small area, it is possible to manage with one unit designed for the corresponding heat transfer. It is undesirable to install the furnace close to the outer wall, because it quickly cures. The place chosen for laying the furnace is carefully measured taking into account the following points:

- the state of the ceiling, allowing you to easily bring the chimney out;

- the possibility of preparing the foundation, which needs to be made 100-110 mm larger than its foundation;

- the absence of nearby structures made of combustible and flammable materials.

The chimney, when it is routed through the ceilings and the attic, must not run into load-bearing beams and roof rafters.

Materials and blanks

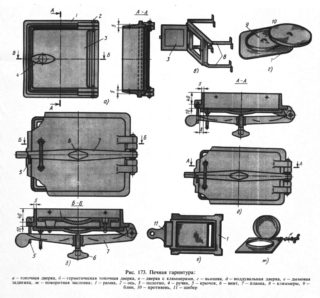

The range of components and the volume of required building materials depend on the type of furnace design chosen, within which they differ little. For purely heating samples, it is not necessary to lay a hob, an oven, and also a water tank in the project. A typical set of elements made of cast iron and steel includes the following items:

- door for an ash pan and its furnace analogue;

- doors of treatment channels;

- chimney valve;

- burners;

- hob itself.

Rounding out this list is a grate, traditionally made of cast iron.

In addition to all of the above, steel parts will be required for the construction of the structure. Their list includes the following items:

- built-in oven;

- tank for water;

- stripes of arbitrary length and width;

- corner size 50x50 mm;

- well annealed wire 2-3 mm;

- steel sheet laid on the firebox.

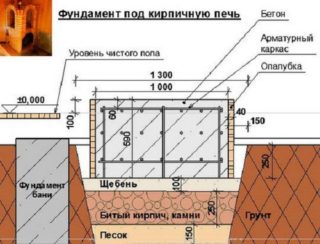

For the manufacture of the base (foundation) and furnace body, it will be necessary to prepare consumables. They are selected based on the selected masonry scheme and taking into account a special table, usually attached to it.

This list includes:

- crushed stone, rubble stone, as well as broken brick, simple sand and cement;

- boards for arranging formwork under the foundation and a piece of roofing material for waterproofing;

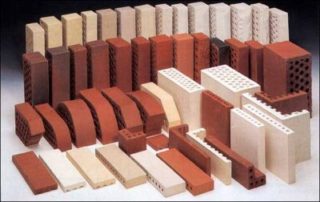

- bricks of two types;

- asbestos sheet and marking cord;

- source components for the preparation of clay solution.

As an alternative to the traditional composition for laying the furnace, a ready-made heat-resistant mixture is often purchased.

Marking and subsequent arrangement of the base

Before you build a brick oven with your own hands, you need to carry out a number of preparatory measures. Laying operations of the furnace structure are preceded by marking and pouring the foundation, capable of supporting its weight. Before choosing a place, it is important to consider that when passing through the ceiling the chimney should be laid out away from wooden beams (at a distance of at least 120-150 mm). To accurately mark the area where you need to cut the boards in the floor, you will need a plumb line, the twine of which is fixed in the right place on the ceiling. Moving the plumb line from one corner to another, they outline a square corresponding to the shape of the proposed foundation (with a margin).

According to the markup obtained, the boards are carefully cut out, after which access to the ground is opened. In this place there will be a stove foundation, not connected with the foundation of the whole house - the shrinkage of these two buildings is different. In the exposed soil, it will be necessary to prepare a foundation pit of 0.5 meter depth, and then proceed with the arrangement of the foundation, built from rubble stone or brick battle. In the first case, formwork is not required; it is enough to lay clean stones at the bottom, poured in layers with concrete mortar. When laying, it is important to make sure that there are no clearly visible voids between the rubble blanks.

Upon reaching the surface of the earth, stones should be placed in a special form in the form of a box, limited to the formwork boards and closed from the inside with a layer of polyethylene. When laying the boot, it should be ensured that the upper cut of the foundation is located below the floor level by about 140 mm. The surface of the obtained base is leveled and left to dry completely.

Masonry preparation

The main materials used in the construction of a brick stove with their own hands are ordinary red brick and its fireclay refractory analogue. The first is used only for the construction of the outer shell of the structure, the walls and the bottom of the furnace are made of the second. The purchased brick is carefully selected - only whole samples are selected without chips and cracks. When used material is used, each sample is thoroughly cleaned of soot and solution, and then soaked in water for half a day. Before use, it is enough to rinse the fireclay blanks with clean water, which will remove the accumulated dust from them.

Preparation of brick blanks

Preparatory operations also include the production of incomplete brick billets obtained by splitting whole samples. When laying the furnace, you will need:

- halves;

- three-quarter blanks;

- quarters and other small fragments.

To facilitate the preparation of bricks in size, marks are made on the pickaxe handle.

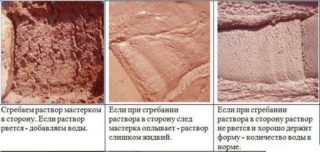

Solution preparation

The strength and durability of brick kilns depend on the condition and condition of the masonry mortar, which guarantees a high-quality seam. Its thickness should not exceed 8 mm, because otherwise, cracks appear at the joints and the heating efficiency decreases. The solution is prepared only from high-quality clay and carefully sifted sand.It is brought to a homogeneous mass that does not have lumps and impurities in its composition.

Regardless of the type of solution used (skinny, normal or oily), when mixing with a water component, you need to monitor the consistency of the mixture. It should look like a thick dough that does not stick to a person’s hands and trowel. To lay refractory bricks, you will need to prepare a special solution, which includes greasy clay and fireclay sand, taken in a one to one ratio.

Installation Recommendations

As soon as the foundation is ready, the bricks, mortar and all the necessary details are purchased, go to the marking of the initial or first row. It is the basis of the design and is laid out according to a previously prepared drawing. A sheet of roofing material is taken and laid on the foundation with a slight indentation from the edge, and then blanks of the first row are laid out along its perimeter dry. First you need to add the corners, and then fill the gaps with the same bricks with a gap of 5-6 mm (they are subsequently filled with mortar).

As soon as the foundation is ready, the bricks, mortar and all the necessary details are purchased, go to the marking of the initial or first row. It is the basis of the design and is laid out according to a previously prepared drawing. A sheet of roofing material is taken and laid on the foundation with a slight indentation from the edge, and then blanks of the first row are laid out along its perimeter dry. First you need to add the corners, and then fill the gaps with the same bricks with a gap of 5-6 mm (they are subsequently filled with mortar).

It will be possible to get them well if you use the building level and the goniometer. To make sure that the row is laid out evenly, you should measure its diagonals, which should be the same in length. The next row is laid out on the solution, which fills the gaps of the first. When it is laid out, a very thin layer is applied to the corner blanks with an increase in its thickness on all subsequent elements. In the process of laying, according to the instructions, a level is placed on two bricks laid side by side, one of the sides of which is pressed onto the second workpiece, aligning it horizontally. Do the same with the 3rd and 4th bricks (and so on according to the step-by-step scheme).

Masonry execution (ordering)

In order for the masonry of the initial rows to turn out to be even along the entire perimeter of the furnace, from the outside it will be necessary to vertically stretch the plumb cords attached at several points on the ceiling and floor. Next, we proceed to the calculation of the remaining rows, the quality of which depends on the following factors:

- the correct application and distribution of the solution on the working plane;

- evenness of laying bricks;

- compliance with the gap between them.

At this step, with the help of a trowel or a spatula, the solution is already laid out on the previous row and neatly aligned with a layer with a thickness of about 9-10 mm. The first corner brick lighthouse is immediately laid on it. Then the same solution is applied to the end of the second, which is immediately laid down, pressed to the previous one and tapped with a hammer. When conducting masonry, it is important to comply with the order, according to which the joints of each subsequent row are shifted relative to the previous one.

Upon completion of masonry work, you should leave the oven to dry, to accelerate which it is recommended to open all windows and doors. To reduce the natural drying time of the furnace, you can put a 200-watt bulb included in the network into its furnace. Another option is to place a fan heater in front of the door.