Thermal insulation of trunk pipelines can reduce temperature loss and protect communications from freezing in the winter. For maximum efficiency, a material with low thermal conductivity and a long service life is required. Such insulation is rockwool Rockwool Tech Mat - a specialized product for insulation of pipelines of aboveground and underground laying.

Rockwool Tech Mat Material Description

Mats Rockuvl Tech Mat are made from a melt of basalt rocks with the addition of a synthetic binder. In the manufacturing process, mineral wool is treated with a hydrophobic compound. The material belongs to the group of technical thermal insulation. It was created to reduce heat losses of pipelines and tanks, to isolate ducts and air conditioning systems, to prevent condensation and freezing of communications.

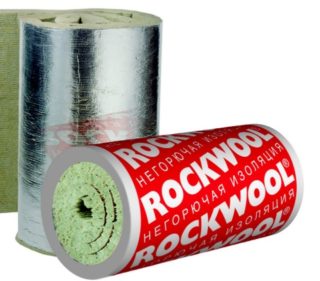

Tehmat Rockwool slabs are characterized by low weight and density. Randomly spaced stone wool fibers provide low thermal conductivity. Products are offered with one-side lamination with aluminum foil and without additional coating. Technical mats with foil have the properties of a vapor barrier membrane. They are intended for highways with cold water. Products are rolled up and packaged in a protective plastic film with a company logo.

Specifications

In terms of performance, Techmat Rockwool is ahead of many materials in its class:

- thermal conductivity - at 10 ° - 0.034, at 25 ° - 0.036 °, at 300 ° - 0.120 (W / m * K);

- density - 43 kg / m3;

- compressibility - up to 45%;

- operating temperature - from 180 ° to 570 ° C;

- water absorption - 1 kg / m2;

- fire safety class - KM0, for foil models KM1;

- organic matter content - 2%.

Due to its layered structure, mineral wool passes steam, maintaining the moisture balance of insulated structures.

Advantages and disadvantages

The solution to the problem of energy conservation in the field of housing and communal services was the use of technical insulation Rockwool. The brand's products are resistant to a wide range of temperatures, prevents the spread of fire, reduces noise.

The main advantages of mats:

- Energy Efficiency - Due to the low coefficient of thermal conductivity, energy losses are significantly reduced over the entire length of the pipelines. When sealing mats during installation on structures with high temperature, the indicator becomes less than the calculated value.

- Resistance to moisture - water-repellent composition prevents the absorption of moisture and wet insulation.

- No shrinkage - hard stone fibers do not undergo deformation under load. Elastic plates retain their original shape, preventing the formation of cracks for heat leakage.

- Durability - over the years of service, the insulating properties of the material are not reduced. The company gives a guarantee for 50 years of operation of mineral wool.

- Safety - materials are manufactured in accordance with environmental standards. They are safe for people and the environment.

- Incombustibility - stone fibers do not support combustion. Tehmat plates belong to non-combustible materials, and when applying aluminum foil - to low-combustible materials.

- Biological and chemical resistance - stone wool does not support the growth of mold and fungi, even in conditions of high humidity. The material is resistant to oils, solvents, alkalis.

The insulation does not have technical flaws; only the high cost of specialized goods can be attributed to the minuses.

Scope of use of Rockwool Tech Mat insulation

As thermal insulation, mineral wool is used for heating networks, cold water supply, various technological equipment. High fire resistance allows you to install mats on air ducts, increasing fire safety. Insulation is used for insulation:

- Heating mains (water and steam), located in the open air, in tunnels, unheated rooms and basements.

- Communication networks of cold water supply in private and civil engineering. Basalt insulation is recommended for pipes of small diameter, the liquid in which freezes at low temperatures.

- Technological pipelines of the food and pharmaceutical industries.

- Connecting flanges and fittings of highways.

- Box of metal chimneys, ducts and air conditioning systems.

Mats are also used for insulation of tanks, heat exchangers and other technological equipment. Convenient dimensions and flexibility of the material simplify installation on non-standard design structures.

Product range

Heat-insulating mats Tech Mineral wool mat can be divided into 2 main groups:

- lamination with foil lamination;

- uncoated insulation.

The linear dimensions of the mats are:

- length - 5000.4500, 4000 mm;

- width - 1000 mm.

Also, the manufacturer's assortment varies in the thickness of the plates. This indicator directly affects the effectiveness of the insulation.

Tehmat 50-60 mm - mineral insulation of the smallest thickness are available in standard sizes 5000 × 1000 mm. Plates on 5 m2 are placed in one package. Products are recommended for multi-layer insulation.

Tehmat 70-90 mm - basalt heaters of considerable thickness are offered in lengths of 4,500 and 4,000 mm. The buyer receives respectively 4, 5 and 4 m2 of material. Plates are used for single-layer and multi-layer insulation of technological equipment and highways.

Mounting technology

Mineral wool plates are used for insulation of pipes with a diameter of 45 mm. The insulation wraps around the object, each coil partially overlaps the previous one. This technology eliminates the bridges of cold. Mats are fixed with a bandage tape or wire with a cross section of 2 mm. When installing a multilayer structure, 3 rings per 1 m of insulation will be required. Plates of the second and third layer should overlap the joints of heat insulation materials laid earlier. Installation of insulation is carried out only in dry weather.

When mounting on pipelines with a diameter of 219 mm or more, wire pendants are additionally used. They are placed between the bandages and fixed on the pipeline. If the insulation is performed with mineral wool lined with foil, then the seams are glued with foil tape. The technology of flange insulation requires sewing hooks on the mats for subsequent fastening of the buckle band. Also, insulated fittings are clad with fiberglass.

Rockwool Tech Mat thermal insulation mats have a service life equal to the service life of insulated structures. The material does not lose effectiveness for 50 years. The simple installation and reliability of basalt wool makes it the best choice for insulation of pipelines and equipment.