Mineral wool is popular as a heater due to its low cost, ease of use and durability. It is important to choose the right type of material and lay the mineral wool on the ceiling. Otherwise, during the first months of operation, it will lose up to 40 percent of thermal insulation qualities.

Pros and cons of mineral wool for ceiling insulation

Minvata is considered the most environmentally friendly heat insulator. It differs from polystyrene in that it does not emit harmful substances even when heated. In addition to this, she has other advantages:

- does not decay;

- vapor permeable;

- not afraid of mechanical stress;

- not subject to damage by rodents and insects;

- holds heat well;

- possesses soundproofing properties;

- easy to install;

- durable

- It is relatively inexpensive.

An important plus is that cotton wool is fireproof, it does not support combustion and does not create smoke.

The main disadvantage is the absolute absence of moisture resistance. Upon contact with the liquid, it quickly gets wet and deformed, loses useful qualities.

How to choose mineral wool

The most commonly used universal stone mineral wool to warm the ceiling. But for thermal insulation of wooden houses, glass wool is sometimes chosen. Its disadvantage is that if the material is not carefully isolated, its sharp particles can get on the skin and in the respiratory tract, which leads to irritation. There is also slag wool, but it is used rarely and exclusively for production facilities.

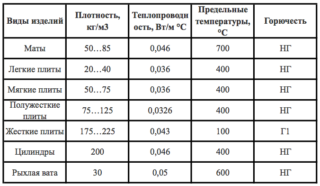

Density

To choose mineral wool for insulation of the ceiling, it is necessary to take into account its brand depending on the density. This is indicated in the labeling in numerical value in kg per cubic meter. m:

- P-75. It is used for thermal protection of horizontal surfaces that do not experience serious loads, insulation of oil, gas and central heating pipelines.

- P-125. It is used for thermal insulation of bulkheads, ceilings, floors and walls indoors, as well as for protection against extraneous sounds.

- ПЖ-175. Dense material, which has a fairly high stiffness, is used as insulation for floors and walls, which are made of metal profiled sheets or reinforced concrete.

- ППЖ-200. It also has increased rigidity. The difference is that ППЖ-200 is the most fireproof.

Mineral wool for insulation of the ceiling is available in two types: in rolls and mats. There is no fundamental difference. But if you have a skylight, it’s better to use mats for fastening.

Pay attention to the storage location, which should be indicated on the package. Do not purchase wet or damp building materials.

Thickness

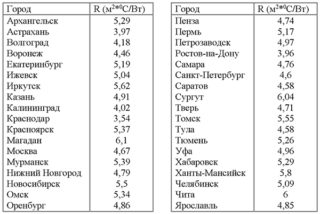

The thickness of mineral wool varies from 2 to 20 cm. The main thing you need to decide on is the number of layers of insulation and the climate of the area. You can calculate the required amount of mineral wool based on SNiP 23-02-2003. A layer of 10 cm will be sufficient in a warm region. In a cold village, it will be necessary to increase this parameter by 1.5–2 times.

It is necessary to take into account the material used for the construction of the building. In the presence of concrete floors, it is better not to use mineral wool less than 10 cm thick.

The thickness of the insulation installed on a flat horizontal roof can be significantly less than for a pitched roof.For those buildings in which there is a heated attic, an 8-cm layer is enough.

Tools and materials

For installation work, in addition to the insulation itself, you will need:

- waterproofing and vapor barrier film;

- plastic dowels, umbrellas;

- profile and suspensions for him;

- wooden rail;

- self-tapping screws.

Of the tools you need a sharp knife, scissors for metal or a jigsaw, a stapler.

When working with mineral wool, personal protective equipment should be used - glasses, clothes, a respirator and mittens.

Ceiling preparation

Mineral insulation can be laid not only on a flat, but also on a non-standard surface. But before insulating the roof, it is necessary to calculate the amount of cotton wool and other materials, prepare tools and personal protective equipment.

Rolled steam protection and waterproofing from the roof side are hemmed at the very beginning. It protects the cotton layers from the negative effects of moisture and steam.

Unpack the cotton wool immediately before installation. After finishing work in the room, they carry out cleaning with a vacuum cleaner, and then take a warm shower.

DIY styling technology

Ceilings between floors and the attic are made of load-bearing beams or reinforced concrete slabs. In the first embodiment, the insulation is usually placed in the space between the floor beams or on the created crate, and in the second - on the surface of the plates.

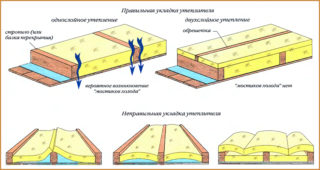

An inter-beam installation method is used if the thickness of the plates or the roll layer of the material is comparable to the size of the beams themselves. If it is impossible to fulfill this condition, combined thermal insulation is carried out.

The technology of laying in inter-rafter space involves the implementation of installation operations in the following order:

- Using the level, determine where the lower sections of the rafters are located. If abnormalities are found, increase the "recesses".

- After the alignment is carried out, cut the coil or plate insulation with a knife or hacksaw into workpieces of the required size, taking into account the distance between the beams, and lay in niches. The width of the cut tiles should be greater than the inter-rafter distance by approximately 2-3 cm. If the heat-insulating material is installed in several layers, the blanks of the second and subsequent layers are placed with offset joints.

- Fix the laid tiles from below with a battens and close the heat insulation layer with vapor barrier, securing with a stapler.

Next, the surface is sheathed with drywall or plywood. Finish the work with decorative trim.

Insulation of the ceiling over the rafters in a private house with do-it-yourself mineral wool:

- On the upper cut of the rafters, mount a crate of thin rails, on which then lay the blanks of mineral insulation.

- At the bottom cut, fill another crate of the same rails, onto which, with the help of a stapler, fix the vapor barrier film.

- Lay and fix a layer of waterproofing material on top, and then plaster it with plasterboard or plywood.

In a similar way, mineral wool is attached to reinforced concrete slabs. So they create protection from the cold, not only in private homes, but also in other buildings.

The use of mineral wool allows warming the ceiling of the attic and provide high-quality thermal insulation of the bath.

Cost of insulation

Making an estimate, in addition to the prices for mineral wool and installation work, it is necessary to take into account the cost of vapor barrier - about 40 rubles per square meter, and the cost of installing the frame base - about 100 rubles per square meter. m. in the presence of their own material. If it is not, the cost will grow up to 170 rubles.

Installing mineral wool with a thickness of 10 cm costs an average of 100 rubles per "square".If the insulation is thicker, the price will increase by 1.5–2 times, since it is more difficult to mount it.

But all these expenses will subsequently pay off on heating. If you insulate the ceiling with mineral wool, heat loss even in cold regions can be minimized.