The bathhouse became a part of everyday life and entered the culture of the Russian people back in the days of paganism. And today, she continues to enjoy well-deserved love. This is not just a place where you can wash yourself, but also treatment, relaxation and communication. Owners of private homes often think about building their own bathhouse. And the heart of any bath is a heating boiler. Depending on the energy source used, boilers are of several types: liquid fuel, solid fuel, electric and gas. If the site is gasified, the choice in favor of a gas boiler is obvious.

Advantages of gas boilers

- No need to prepare fuel. It saves time and money.

- Clean to use. No need to constantly remove garbage, soot and soot.

- Efficiency. A properly selected boiler warms the steam room in less than 1 hour.

It's important to know! Calculation of the power of a gas burner is based on a proportion of 252 kcal per 0.4 m3. Calculation example: the steam room has dimensions of 2x1 5 x 1.7 meters. The volume is 5.1 m3. 5.1 / 0.4 * 252 = 3213 kcal.

To convert kcal to kW, we use the coefficient 0, 001163. 3213 kcal x 0.001163 = 3.7 kW.

It is better that the capacity of the selected boiler exceeds the calculated one. This will increase its service life. The required power of the gas burner may depend on a number of other variable factors.

A gas equipment specialist can help determine power based on these factors:

- Profitability. Natural gas is a cheaper fuel than diesel fuel or firewood.

- Easy to operate.

- Safety. Modern gas equipment is equipped with a gas control system. If the burner goes out, the gas supply will shut off automatically.

And so you came to the store to buy a gas boiler for a bath. The manager in the store will give advice, talk about the disadvantages and advantages of different options. Basic knowledge will help to understand the information and choose the most suitable model.

Classification of gas boilers by type of installation

Floor gas boilers for a bath are installed on the floor or on a special platform. Floor boilers usually have an open combustion chamber. They are durable, compact.

Attention! Before installing the equipment, it is necessary to obtain permission from the gas services.

Rules for installing floor gas boilers:

Rules for installing floor gas boilers:

- Boilers for baths are installed in the steam room so that the front side goes into the dressing room. To do this, in the wall between the steam room and the dressing room make a window corresponding to the size of the burner.

- Proper operation of any gas equipment implies the presence of exhaust ventilation in the room or a window with a window.

- The necessary distance between the boiler and the walls is at least 50 cm.

- Walls located in close proximity to the boiler are faced with refractory material (stone, brick, metal).

- As a base, a metal sheet is laid on the floor under the boiler. The dimensions of the base are calculated based on the dimensions of the boiler. It should protrude from under the boiler on each side by at least 10 cm. In some cases, the floor boiler is installed on a special support. As a rule, the need for a platform arises when installing old-style models.

Assembly of supports for a gas boiler

A special platform for the boiler in the bath is made of a metal corner in the form of a spatial structure having the shape of a cube. Vertical and horizontal elements are connected at an angle of 90 degrees. The length and width of the cube is determined based on the overall dimensions of the gas boiler at its base.The cube height depends on the characteristics of the boiler model and is determined by a specialist who installs a heating and water supply system.

Wall mounted gas boiler placed on a wall or a special frame. Such boilers do not take up much space. You can safely buy a wall-mounted boiler for installation in a small bathhouse. They have a closed or open combustion chamber, are easy to install, do not require installation of additional equipment. The standard package includes all additional life support systems: a circulation pump, gas control, shutoff valves, a fan. The boiler is controlled automatically. It is enough to set the desired temperature indicator of water in the heating and water supply system.

Wall mounted gas boiler placed on a wall or a special frame. Such boilers do not take up much space. You can safely buy a wall-mounted boiler for installation in a small bathhouse. They have a closed or open combustion chamber, are easy to install, do not require installation of additional equipment. The standard package includes all additional life support systems: a circulation pump, gas control, shutoff valves, a fan. The boiler is controlled automatically. It is enough to set the desired temperature indicator of water in the heating and water supply system.

Disadvantages of wall-mounted boilers:

- Durability (service life is 10-12 years);

- Limited power;

An important component of a gas boiler is a burner. Burners are divided into two types: atmospheric and inflatable.

The first are inexpensive, work silently. A simple example of such a burner is a gas stove burner. Atmospheric burners are installed in boilers with an unlocked combustion chamber. To maintain combustion, oxygen enters the air-gas mixture directly from the room. Exhaust gas leaves through a chimney due to natural draft. Inflatable burners have a higher gas efficiency and ensure even heat supply. They are used in closed combustion chambers. To maintain combustion, oxygen is forcibly pumped using a built-in fan. In boilers with inflatable burners use forced draft. A big plus of these burners: they do not burn oxygen in the room.

Chimney Types

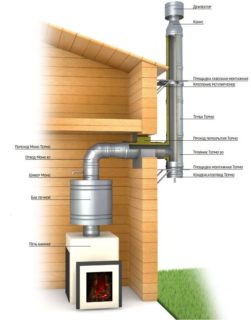

Natural draft chimney. It is used for boilers with an open combustion chamber. When installing a chimney, certain requirements must be taken into account:

Natural draft chimney. It is used for boilers with an open combustion chamber. When installing a chimney, certain requirements must be taken into account:

- The pipe must be at least 5 m high from the burner level to create good draft.

- When assembling the chimney, the pipes are connected in the course of combustion.

- The junction of the gas boiler and the chimney must be airtight.

Natural draft flues are independent of power supply. But they have a number of disadvantages:

- Firm binding of the boiler to a specific place;

- Time-consuming complex installation;

- Bulkiness;

- The high cost of materials and installation compared to a coaxial chimney.

A coaxial chimney, when compared to a natural draft chimney, has many advantages. Installing such a chimney is simple.

The coaxial pipe is horizontally discharged into the street through a small hole in the wall. This significantly reduces financial costs and saves time. A coaxial chimney device requires a fan to create a forced draft. All boilers with a closed combustion chamber have built-in equipment for the forced removal of exhaust gas.

Disadvantages:

- Power Dependence

- Noise during operation of the boiler.

Classification of gas boilers for a bath by functionality

There are two types of gas boilers:

There are two types of gas boilers:

- Single-circuit.

- Bypass.

Single-circuit boilers are designed for heating. They are arranged quite simply and have a relatively inexpensive cost. In addition, the installation of such boilers is not particularly difficult. If you wish, you can convert a single-circuit boiler to provide hot water. For this, an indirect heating cylinder is installed in the heating system, i.e. a boiler. The tank is filled with water as needed. The heating pipe passes through the boiler and heats the water. Such a water heating system is economical and does not require additional gas consumption.

Single-circuit gas boilers are easy to operate, reliable and have a long service life.

Double-circuit boilers are a more complex and expensive unit.One circuit provides heat, and the second for hot water. The control system in such boilers is automated, the temperature of heating and hot water is set independently of each other. Double-circuit boilers consume more gas than single-circuit ones. This is a case where profitability is sacrificed for convenience. Water in double-circuit boilers can be heated in two ways:

- The first way. Circuit heating in a flow heat exchanger. Obvious disadvantage: some time after turning on, cold water flows from the tap. The gas flow rate with this method increases.

- The second way. The use of a storage tank for heating water. In this case, the water maintains the set temperature for a long time, which saves gas consumption.

It is important to determine the choice of the boiler at the design stage of the bath. If you have brought the required parameters of the bathhouse and boiler into correspondence, then light steam is provided to you.