A specialized set of equipment designed to control the heat supply of individual buildings connected to a central heating system is called an individual heat point. It can be a residential building, enterprise or any other construction with several independent heat consumers.

An individual heat point solves such problems as:

An individual heat point solves such problems as:

- ensuring stable performance in the system;

- use of a separate heat carrier;

- heat distribution between consumers;

- protection of internal systems of the house from abnormal values of temperature, pressure and other characteristics;

- more accurate accounting of thermal energy.

The heat carrier from the centralized heating system enters an individual heat point. Usually this is industrial water with a high concentration of salts and other impurities, which is undesirable to supply to the final consumer. Therefore, in the ITP, through special heat exchangers, the internal coolant is heated, which can be purified water or special mixtures based on glycol.

Such a separation of circuits allows you to install aluminum radiators and other devices in the house that require cleanliness of the coolant. In addition, the internal heating system is reliably protected from pressure surges and water shocks that regularly occur in the district heating system.

ITP is usually divided into three types according to capacity:

- small (controlled thermal power does not exceed 40 kW);

- medium (40-50 kW);

- large (up to 2 MW).

The first two types are usually installed for large private houses or small apartment buildings, and the large ones - in houses with a large number of apartments or for industrial facilities. When choosing the power of ITP, engineering calculations are carried out to accurately assess the necessary characteristics.

The advantages of individual heating points

ITP installation provides end users with a number of significant advantages. The requirements for the reliability of heating appliances are reduced, so that in apartment buildings you can install aluminum and other radiators, which can only be used in autonomous heating systems. Accident rate is reduced due to excess pressure or temperature.

Thanks to the automation of distribution of the coolant, it is possible to reduce non-target heat consumption by 15%, to reduce electricity consumption by more than 25%. Heat losses are reduced, the accuracy of calculating heat energy increases. At the same time, comfort directly in the premises increases significantly. Significantly reduced the cost of installing the appropriate communications, since pipes and devices should not be designed to work with chemically active water.

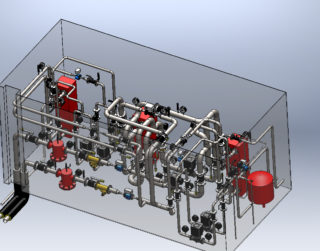

ITP device

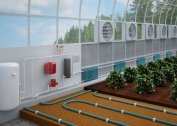

An individual heat point is usually located in the basement and contains such nodes as:

An individual heat point is usually located in the basement and contains such nodes as:

- heating system input;

- meters for metering heat transferred to consumers;

- pressure matching devices;

- connection of heating and domestic hot water circuits;

- ventilation connection.

The number and characteristics of individual nodes depend on the specific project. Mandatory are only nodes of input, accounting and coordination of pressures.

ITP Operation Principle

When using an ITP, the in-house heating system is constructively a closed loop in which the cleaned coolant circulates.This is usually water or a specialized glycol-based mixture designed for use in private heating systems. Naturally, even in a closed circuit, leaks can occur, therefore, a mechanism for compensating the amount of coolant is always provided.

The second key feature of ITP is that hot water is supplied to the hot water system from the cold water system. Thus, the consumer receives purified water not only in a cold, but also in a hot tap. In addition, clean water does not harm pipes, which reduces material requirements.

Installation of an individual heat point

When the project is drawn up and all the necessary equipment is selected, they begin to complete. Before proceeding with the installation, you must make sure that all the necessary equipment is on sale, so that you do not have to change the specifications on the go, when some of the elements have already been purchased. Further, the equipment is mounted according to the project, instrumentation devices are connected. When the system is launched and tested, a fully finished, debugged and verified object passes the final inspection and is delivered to the customer.

When the project is drawn up and all the necessary equipment is selected, they begin to complete. Before proceeding with the installation, you must make sure that all the necessary equipment is on sale, so that you do not have to change the specifications on the go, when some of the elements have already been purchased. Further, the equipment is mounted according to the project, instrumentation devices are connected. When the system is launched and tested, a fully finished, debugged and verified object passes the final inspection and is delivered to the customer.

During the installation process, all input nodes are necessarily equipped with shutter dampers, which allow switching off the coolant supply at any time in the event of an accident. When connecting to a centralized heating system, it is necessary to choose fittings with a connecting diameter exceeding 32 mm. Mesh filters (sumps) must be installed to protect the system from rust fragments and other contaminants. Norms of SNiP require that mud traps are installed in the ITP in front of each locking and regulating device.

The heat metering unit is developed separately, so its installation is carried out according to a separate project. Only heat meters approved by regulatory organizations are used here. When choosing meters, it is necessary to make sure that even at peak times, the heat or coolant flow rate will not exceed the boundary values acceptable for a particular flowmeter model. Possible pressure losses in the meters are also taken into account.

The pressure matching unit protects the internal circuit from water hammer, boiling of the coolant and other undesirable consequences arising from pressure drops. The same unit limits the flow and provides hydraulic balancing of the circuits. When using an open system, a direct thermostat is installed. In closed systems it is recommended to install plate or capacitive heaters. Plate devices are suitable for large ITPs; capacitive devices are suitable for small ones.

Features of operation of ITP

An individual heat point must be serviced by qualified personnel, since if there is a lack of qualification, the risk of emergency situations increases. It becomes especially great during the most critical periods of severe frost. All employees should be familiar with the safety rules and operating conditions of ITP equipment.

It is forbidden to turn on the pumps with an empty circuit, as well as with closed cranes. During any changes in operating modes, it is necessary to monitor the pressure gauges on all nodes where they are installed. It is absolutely necessary to control the temperature indicators of electric drives, to ensure that there are no strange sounds and excessive vibration. It is strictly forbidden to dismantle or partially disassemble any devices in the presence of pressure. With any adjustment, it is forbidden to exert excessive forces to move the regulators.