Organization of the production process is a multifaceted task in which all factors must be taken into account. In addition to equipment and skilled workers, particular attention should be paid to maintaining the optimum room temperature. To do this, you need to develop systems and schemes for heating workshops with your own hands: welding, carpentry, production.

The choice of heating according to the characteristics of the room

Before you make your own workshop heating, you need to find out several important characteristics. First of all - the optimal temperature in the room. The choice of a heating system directly depends on this.

When drawing up a heating scheme for a carpentry workshop or other production areas, the following parameters should be taken into account:

- Area and ceiling height. If the distance from the floor to the roof is more than 3 meters, then convection (water, air) systems will be ineffective. This is due to the large volume of the room;

- Thermal insulation of walls and roofs. The heat loss of the building is the first thing to consider when choosing. The heating system for the workshop should be not only effective, but also economical. In this case, it is best to use zonal heat sources. They will maintain a comfortable temperature level in a certain area of the room;

- Technological requirements for optimum temperature in the workshop. For example, the heating of a woodworking workshop should keep the air heating at a constant level. Otherwise, it will affect the quality of the products. If the initial raw material is metal, then a comfortable temperature is needed only for workers.

To conduct this analysis, you will need to study the advantages and disadvantages of each type of heating. Consider the most efficient heating of the production hall, which differs depending on the scheme and the components used.

Workshop air heating

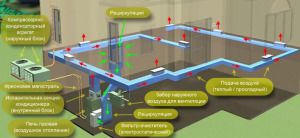

For large rooms with high temperature requirements, it is recommended to use air heating of the workshop. This system is an extensive network of air channels, in which flows of hot air move. Its heating takes place using a special air conditioning system or gas boiler.

Such systems and schemes for heating workshops with their own hands are applicable for welding, carpentry, and industrial premises. The main structural elements of this system are:

- Outdoor air intake. It includes fans and purification filters;

- Further, the air masses through the channels enter the heating zone. It can be electrical appliances (spiral element) or gas installation with an air heat exchanger;

- High-temperature air masses move through channels that distribute heat to individual production rooms. A throttle is installed in each outlet to control the level of the heating temperature.

Such an air heating system of the workshop has a number of significant advantages over the standard. The main one is the optimal heating of the room. Correctly located air channels can have guiding elements that focus air flows into the desired area of the workshop.

Also, with an additional installation of an air conditioner, the same system can be used as a cooling system. However, such a heating scheme of the workshop is rather complicated in terms of design.Before self-installation, you need to calculate the power of the fans, the shape and cross section of the air channels. Therefore, it is recommended to use the services of specialized companies for the installation of air heating in a production hall.

Workshop water heating

The use of traditional water heating is relevant for small industries whose workshop area does not exceed 250 m². It is necessary to constantly maintain the air temperature at an optimal level throughout the volume of the room. Often the heating of woodworking shops is done by water.

This is due to wood waste production. For their disposal, a solid fuel boiler with long burning is installed. This work scheme allows not only quickly, but also to effectively get rid of wood waste. They are later used as fuel.

However, this scheme of organizing heating has a number of nuances:

- In order to maximize the heating efficiency of the production hall, it is necessary to significantly increase the area of heating devices. For this, pipes of large diameter are used, which are welded together into registers;

- Inertia. It takes a sufficiently long time to heat the air in the workshop from the coolant;

- The inability to quickly change the temperature of the water in the pipes.

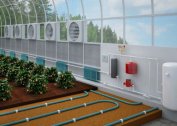

However, along with this, when installing water heating in the welding workshop, you can use a warm floor system. Such a scheme will help reduce the required area of heating appliances. At the same time, the inertia of the system will decrease - the air in the workshop will heat up faster.

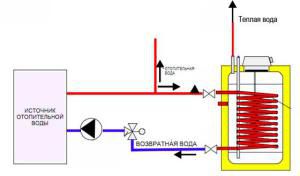

During the design of heating, it is possible to provide for the organization of hot water supply, which is important for many production processes. To do this, you need to purchase (or make) a heat exchange tank for heating the workshop with your own hands.

In it, the coolant energy will be transmitted through the coil to the water. This will make it possible to use hot water not only for domestic needs, but also for production processes.

In addition to solid fuel boilers, you can install other types of heating equipment:

- Gas boilers. Effective economically if there is no cheap solid fuel;

- Electric heaters. They are preferably not used, since the cost of electricity will be high;

- Liquid fuel boilers - diesel or used engine oil. Install if there are no gas lines. Economical, but inconvenient in that special containers for storing fuel are needed.

For the use of water heating circuits of the workshop, it is necessary to correctly calculate the power of the heating installation.

The standard ratio of 1 kW of released heat energy per 10 m² of area is relevant only for a workshop whose ceiling height does not exceed 3 meters. If they are higher, then each additional meter is + 10% to the boiler capacity.

Workshop infrared heating

The principle of operation of infrared heaters is to heat surfaces due to the influence of IR cure. If the heating system of the welding workshop is designed for spot heating of certain areas, then it is best to use these devices. Effective heating with workshop infrared heaters should begin with a selection of heating elements. Currently, two methods of generating infrared radiation are used.

Carbon Heaters

Its design consists of a bulb, inside which is a carbon spiral, and a reflective element. When current flows through the heating element, it glows due to high electrical resistance. As a result of this, IR radiation is emitted.

To focus thermal energy, a reflector made of stainless iron or aluminum is provided.

IR electric heaters can be used as additional heating for the carpentry workshop. They are mounted over those working areas where a stable temperature regime is required. The advantages of electric infrared heaters include:

- Simple installation;

- The ability to control the heating temperature by changing the supplied current power;

- Small overall dimensions.

However, due to the high energy consumption, heating with electric infrared heaters for workshops is rare. Instead, they mount gas models.

Gas IR heaters

For production halls with a large area, if necessary, zone heating is recommended to use gas models of infrared heaters. Their principle of operation is based on the so-called flameless combustion of a mixture of gas and air on a ceramic surface. As a result of this, IR radiation is formed, which is focused by the reflector.

For efficient heating with workshop infrared heaters, ceiling models of heaters are often used. It is important to correctly calculate the mounting height and the required power. The heating area and temperature conditions in this part of the workshop will depend on these parameters.

They are used as a heating system for the welding workshop, where a comfortable temperature is needed only to ensure normal conditions for working personnel. However, when planning this type of heating, a number of nuances must be taken into account:

- An infrared heating system for a workshop cannot be used if air heating is needed throughout the room. Heaters are designed for local exposure;

- To minimize costs, only natural gas should be used. The liquefied balloon in addition to the additional purchase of exchange tanks is inconvenient with the periodic connection procedure.

But despite these shortcomings, the use of infrared heating for woodworking shops and other areas of industry remains the best option. However, for the installation of gas heating of the workshop only with your own hands, you need to conduct a series of coordination measures with the gas service in order to get all the permits.

How to choose the right heating system for this or that workshop? It is necessary to take into account its operational parameters, the cost of acquiring equipment and the price of energy. Remember that the cost of production will depend on the heating efficiency of any production workshop.

If you need an economical option for organizing the heating of a carpentry workshop - in the video you can see non-standard methods of heating air using sawdust and wood shavings.