A false ceiling is a design in which the supporting elements are attached directly to the base ceiling. Especially often, such a ceiling is used in the construction of baths, since it most meets the requirements for decorating rooms with a high level of moisture and steam.

How to make a good and high-quality ceiling in a bathhouse, where a large amount of moisture accumulates?

No matter how much we would like, no one has yet repealed the laws of physics: steam has the ability to rise, which creates condensation and accumulates moisture. During the construction of any bathhouse, it is important to take measures to preserve heat and think about how to hem the ceiling, because the ceiling surface in the bathhouse is not only a decoration element, but also an important functional part of the entire room. Usually a bathhouse is built with a second non-residential floor in the attic. In the presence of an attic, a false ceiling can be considered the most popular ceiling in the bathhouse. This constructive solution is within the power of anyone, you just need to get acquainted with some features of the technology of such work.

False ceiling technology for a bath

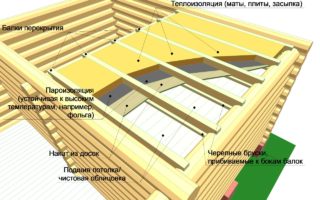

False ceiling technology has several basic principles. First you need to assemble the frame from the supporting beams. This frame must be strong because it accounts for most of the load. For the frame, beams with a certain cross section of 50x150 millimeters are needed, they must be laid on the upper harness. This will be the crate of the ceiling surface. In the process, do not forget about the exit of the chimney. For her, a hole of the right size is made. Then you should start collecting directly the overlap. The ceiling is assembled from various layers, which include waterproofing, vapor barrier, insulation material and lining.

False ceiling technology has several basic principles. First you need to assemble the frame from the supporting beams. This frame must be strong because it accounts for most of the load. For the frame, beams with a certain cross section of 50x150 millimeters are needed, they must be laid on the upper harness. This will be the crate of the ceiling surface. In the process, do not forget about the exit of the chimney. For her, a hole of the right size is made. Then you should start collecting directly the overlap. The ceiling is assembled from various layers, which include waterproofing, vapor barrier, insulation material and lining.

So, you should get the following:

- Boards of the inner lining.

- Beams for overlapping.

- Boards for exterior cladding.

- Vapor barrier.

- Thermal insulation.

- Topcoat.

Installation work

Installation of the ceiling is much easier than the construction of walls or roofs. Installation of a false ceiling will take time and working tools.

Installation of the ceiling is much easier than the construction of walls or roofs. Installation of a false ceiling will take time and working tools.

Beam Frame

The beam for the frame must be free from damage, knots, cracks and other defects. The crate must be treated with an antiseptic, so that during operation, the beams do not rot or undergo various fungal diseases.

Vapor barrier

Vapor barrier is started when the base is ready. A vapor barrier film is attached to the base from the bottom side, which does not release moist air from the room, while loyally refers to the wooden parts of the structure. For fastening use a construction stapler. It is important to take into account the fact that the use of battens will provide a ventilation gap between the ceiling covering and the vapor barrier film. For these purposes, use a conventional plastic film or a special membrane, depending on the budget. It is desirable to make a film with an overlap on the walls, this will provide good sealing of the seams. Often foil is used for vapor barrier: it reflects heat and helps to save it.

Binder Materials

There may be options. Often the binder is made from a draft board, and then, at the finish, the final version of the binder is used. Lining made of quality wood is considered the best option. Boards should be laid without gaps. According to the technology, the board should be fixed with the groove outward, and the next one goes into the groove.

Insulation of the ceiling of the bath

It is necessary to warm the outer side of the ceiling, which goes to the attic. Density for insulation of the floor is twice as high as the insulation for the walls.Since warm air tends to rise, it must hold the air and prevent it from eroding. One hundred millimeters is the smallest thickness. And the thickness of the beams also fluctuates within these limits.

It is necessary to warm the outer side of the ceiling, which goes to the attic. Density for insulation of the floor is twice as high as the insulation for the walls.Since warm air tends to rise, it must hold the air and prevent it from eroding. One hundred millimeters is the smallest thickness. And the thickness of the beams also fluctuates within these limits.

The insulation material is placed on the vapor barrier and must not reach the beams. This condition must be observed, since the resulting gap will serve for air circulation. The insulation must be carefully laid out, it cannot be crushed and tamped, because it can lose its properties.

Waterproofing

The waterproofing layer will protect everything that is under it from the negative effects of weather conditions. As a result, you should get something like a cake or pie. Polyethylene or special material is overlapped. The junction can be closed with tape.

Processing the upper side of the floor

Any boards are suitable for this, they need to be laid with a continuous flooring, then fixed with ordinary nails and covered with any finishing material. But the coating can not be done if the second floor is non-residential. At this point, the binder completes. The interior of the ceiling can also be sheathed with a finish.

Installation of the finish coating is performed by any material for the ceiling surface. Much depends on desire and opportunity.

Filing the ceiling for a bath with your own hands will help you significantly reduce costs, and save money on building material.