Log houses are attracted by environmental friendliness, the ability to retain warm air, creating a favorable climate for living. Practice has shown that the wall of logs with a thickness of 0.24 m in thermal conductivity is comparable to a brickwork of 1 m. But in such dwellings it can also be cold, uncomfortable.

Warming of a log house is necessary if drafts suddenly appear, pulls cold in the legs, the house quickly cools in the winter when the heating is turned off. Why is this happening? There are several reasons. Perhaps the building was built with some deviations from the technology or the construction is old, needs restoration. There are many other reasons why the structure can be cold. The result is one: it is urgent to start thermal insulation, otherwise, with the onset of cold weather, living in it will be, to put it mildly, uncomfortable.

Preparation for work, material, tools

To carry out work on the thermal insulation of wooden buildings, the following materials, tools are needed:

To carry out work on the thermal insulation of wooden buildings, the following materials, tools are needed:

- To install the frame - wooden bars, the width of which is equal to the width of the selected insulation;

- Heat insulating material;

- Hydrobarrier;

- Sheathing materials of log buildings outside;

- Fasteners;

- Construction knife, tape measure, level;

- Hammer, nails, nail clipper, hacksaw for wood.

What materials to choose

How to increase the heat capacity of a log structure, improve the microclimate inside it? It is necessary to insulate the attic with the ceiling, dig up the walls, close up the cracks in the door frames, window frames, windowsill. You will also need to organize a system of floor insulation, possibly the foundation. To conduct thermal insulation of the building, you will need environmentally friendly, "breathing" materials. Artificial heaters are not suitable, they will not allow air to penetrate through the walls, the "greenhouse effect" will lead to rotting of the logs.

How to increase the heat capacity of a log structure, improve the microclimate inside it? It is necessary to insulate the attic with the ceiling, dig up the walls, close up the cracks in the door frames, window frames, windowsill. You will also need to organize a system of floor insulation, possibly the foundation. To conduct thermal insulation of the building, you will need environmentally friendly, "breathing" materials. Artificial heaters are not suitable, they will not allow air to penetrate through the walls, the "greenhouse effect" will lead to rotting of the logs.

Than it is recommended to carry out warming of log buildings:

- For arranging the attic, straw, cellulose cotton wool, wood shavings, algae, mineral wool are ideal;

- It is worth piercing the walls with tow, moss, jute, any tape insulation, based on linen or jute threads;

- After caulking, the house is insulated from the outside using mineral wool and other “breathing” materials.

Expanded wall insulation with expanded clay allows for comfortable living. It has excellent thermal insulation characteristics, while being durable, durable.

If the floor in the room is concrete, sheets of dense basalt wool, polystyrene foam or cork are suitable for thermal insulation. When the floor is wooden on the logs, it is recommended to carry out thermal insulation of rolled mineral wool, filled with natural materials.

Warming of an old or new building should be carried out in compliance with the technology. Particular attention is paid to the choice of heat-insulating materials, which should have the following characteristics:

- Air-, vapor permeability along with the log walls of the home. This quality is especially important for heaters designed for wall cladding from the outside;

- Wall insulation on the outside and inside is carried out using moisture-resistant materials, otherwise the accumulation of steam on the surfaces will cause rotting of the wood, the occurrence of mold;

- To be fireproof, at the same time loose, because their task is to fit snugly against the walls so that there are no voids between the material and the relief log surface.

The work includes a number of measures to ensure the most comfortable stay.To do this, close the cracks in the window openings, the gaps of the door frames, insulate the walls, ceiling, roof and floor.

Ceiling and roof

Thermal insulation of the ceiling of a log house is a must. First, the attic is lined with waterproofing, a heater with a thickness of about 0.25 m is laid on top. If the building is equipped with an attic, it is worthwhile to insulate the floor. The inner surface of the roof is also lined with a waterproofing film, after which mineral wool with a sheet width of 5-10 cm is laid, covered with a membrane material from above.

Wall insulation

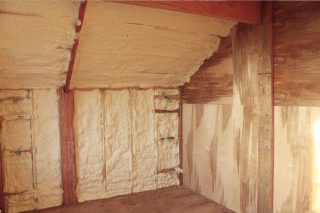

Experts recommend insulating the inner surface of the walls of a log house, and this can be done in several ways.

Experts recommend insulating the inner surface of the walls of a log house, and this can be done in several ways.

Thoroughly pierce the surfaces, carefully seal the door spans, window frames with mineral wool, insulation for interventional cracks. In this case, it is not worthwhile to blow the cracks with mounting foam. The walls of log structures are unstable, dynamic, and foam is non-ductile. Over time, it is deformed, lose functionality.

To warm the walls of the house, you can also sheathe it with a wooden lining. To do this, first mark the walls, then build a frame using metal profiles. After that, the insulation is laid using mineral wool or polystyrene sheets.

The heat-insulating material is fixed with screws or dowels with wide hats, covered with a waterproofing film on top. On the crate, it can be fixed with double-sided or aluminum tape, at the end sheathe the walls with drywall or lining.

There is another way to insulate the walls of a log structure, but it can only be used if the house is heated. First, the surfaces are cleaned by removing the plaster remaining from the previous repair. After this, a framework of reinforcement is installed, a metal mesh with 5 cm cells is placed on top. Then they start plastering the surfaces, applying several layers of plaster. The first is applied to the walls with a liquid composition, the second layer is a primer, thicker, hiding surface defects as much as possible. The final treatment is the application of a thin layer of plaster, which is later covered with paint, glued with wallpaper.

How to insulate the floor

Insulation of the floor in a log house is an important component, creating a favorable indoor climate. When there is no floor, it is equipped using a technology similar to laying on the ground. First, fill, then - laying waterproofing, thermal insulation.

Insulation of the floor in a log house is an important component, creating a favorable indoor climate. When there is no floor, it is equipped using a technology similar to laying on the ground. First, fill, then - laying waterproofing, thermal insulation.

If the floor is lined with wood, at first the voids between the logs are filled with a 10-15 cm thick insulation, a draft is lined on top, and then the final floor.

The concrete floor, more precisely the gap between the main and the “thin” concrete layer, is filled with 5-8 cm thick foam sheet, after which they begin to finish.

It is also possible to insulate the floor using the technology of a ventilated facade, equipping it with a “warm floor”.

Outdoor insulation

External insulation in a log house should be carried out no earlier than 1.5-2 years after the construction of the building. During this time, she will "sit down", the rooms inside will be ready for further warming. The best option for building insulation is the arrangement of a ventilated facade with free air circulation.

First, carefully inspect the walls, cracking cracks, voids. Work is carried out when the window is dry and warm. To close the cracks, they are carefully filled up to the stop with a heater, wielding with a special spatula. After closing the cracks, they begin to wall the walls outside under the siding.

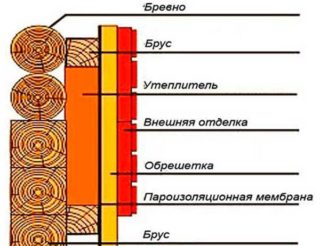

Warming under siding

Most often, a log house is sheathed with siding, plastic panels, lining. The process looks like this. After filling up the cracks, treating the walls with an antiseptic, they begin to equip the ventilated facade. Prepared planes are coated with any vapor insulating material, for example, foil.After that proceed to the arrangement of the crate. For these purposes, vertical wooden slats with a thickness of approximately 2.5 cm are ideal. To ensure optimal ventilation at the bottom and top of the walls, voids of 20 mm wide are left between the main slats. A ventilated layer between the vapor barrier and the wall structure is needed so that moisture does not accumulate under the film, causing mold and rot to multiply.

Most often, a log house is sheathed with siding, plastic panels, lining. The process looks like this. After filling up the cracks, treating the walls with an antiseptic, they begin to equip the ventilated facade. Prepared planes are coated with any vapor insulating material, for example, foil.After that proceed to the arrangement of the crate. For these purposes, vertical wooden slats with a thickness of approximately 2.5 cm are ideal. To ensure optimal ventilation at the bottom and top of the walls, voids of 20 mm wide are left between the main slats. A ventilated layer between the vapor barrier and the wall structure is needed so that moisture does not accumulate under the film, causing mold and rot to multiply.

You can strengthen the vapor barrier at the edges with adhesive tape, then shoot with a construction stapler or nail with nails.

Making the frame is the next step. First, they fill the crate, observing a step equal to the width of the insulation. For work, wooden beams with a width of 100 mm, a thickness of about 45 mm, which are nailed to the surface, are ideal. Then, voids between the guides are filled with layers of heat-insulating material. Plates are laid tightly to each other, trying to keep as few gaps between them as possible. A good heat-insulating material will be sheets of elastic mineral wool with a density of 80 to 120 kg / m3. It fits perfectly inside the crate, it is easily held between the bars without the need for fixing.

When the insulation is laid, the walls are lined with a waterproofing membrane that provides optimal wind protection. This is an important point in the thermal insulation of a building, because on the one hand it must let steam through, on the other hand, it must be additionally delayed. The film to the crate is fixed with a stapler or nails. Docking seams are overlapped, sealed with tape, shot with a stapler or nailed.

The final finish after installing the lathing, insulation - wall sheathing with siding, lining, plastic panels.

The insulation of the facade of a log house can be carried out independently, but if there is no experience in such works, it is better to trust the professionals.

How to insulate the foundation

Thermal insulation of the foundation will make the house even warmer, will become reliable protection against dampness indoors.

Thermal insulation of the foundation will make the house even warmer, will become reliable protection against dampness indoors.

For insulation, polystyrene plates are ideal. First, a trench is dug around the perimeter of the building, reaching in depth to the base. If there is a pillow made of sand and gravel under the house, the first layer of insulation is mounted on it. If there is no cushion, it is worth pouring about 0.1 m of sand mixed with gravel to the bottom of the trench, and then proceed directly to pasting the foundation with polystyrene plates. They are planted on a special glue without organic components, first smearing the vertical surface of the foundation with mastic, gluing the plates in a dotted manner. After laying, the joints are sealed, treated with an adhesive.

To reliably protect the foundation from moisture, to provide heat in the house, you can also use liquid polyurethane foam. The components of the composition are mixed in a special apparatus, then applied to the surface. Liquid polyurethane foam solidifies after 20 minutes, forming a monolithic coating that reliably protects the foundation.

Practitioner Tips

When working with glass wool or mineral wool, you should be careful, you must use personal protective equipment - a respirator, gloves.

If for the organization of insulation there is a choice between polystyrene and mineral wool, the latter should be preferred. The material is more practical, it will not spoil rodents, insect pests.

Log walls should be treated with antifungal compounds, which will increase the durability of the building.

It is desirable to carry out thermal insulation in dry weather, for which the summer season is ideal.

If it is decided to use roofing material as a waterproofing, it should not be strengthened with umbrella dowels. They will damage the material, moisture will penetrate through the holes.

Possible problems and solutions

Independent warming of a log house is an excellent option to save the family budget. However, it is worthwhile to strictly observe the technology, otherwise the alteration of errors will cost much more.What do they pay attention to during work?

Independent warming of a log house is an excellent option to save the family budget. However, it is worthwhile to strictly observe the technology, otherwise the alteration of errors will cost much more.What do they pay attention to during work?

With external wall insulation, before installing the 2nd lathing, it is worthwhile to carry out high-quality waterproofing. It is stacked, fixed with metal brackets, shot with a construction stapler, or nailed with nails. The seams in this case overlap with a width of about 5-10 cm.

The joints are carefully sealed with a self-adhesive sealing tape made of foamed polyethylene with a foil-coated copper layer.

After installing the 2nd crate, the area below should be lined with a metal mesh with small cells. This will protect the walls from the invasion of rodents, pests, woodworms.

Insulation on the outside for siding, lining with clapboard, panels should be carried out after carefully closing up the cracks of window and door frames. For this, a sealant is used, paying special attention to window sills.

Thermal insulation of housing is beneficial for many reasons. Firstly, this will save up to 40% of the family budget on heating a room, which is especially important with a constant rise in price of energy resources. Secondly, living in a warm home is the key to the health of the inhabitants, which is especially important if the family lives with children.