The extraction of natural gas allowed people living in apartments to get comfortable living conditions. Only thanks to the gas pipeline, cooking time is halved, and in the winter it is always warm in the apartment. Unfortunately, for residents of the private sector, such a pleasure is expensive. However, there is a solution. Well, when a biogas plant is built in your own home, it is not difficult to do it yourself. To do this, you need to understand how the chemical reactions proceed, and make a little effort.

What can I get gas from

The main combustible and useful component of biological blue fuel is methane, which is the product of the vital activity of microorganisms. Therefore, for the extraction of biogas, a nutrient mass is required in which bacteria can multiply. As raw materials you can use:

The main combustible and useful component of biological blue fuel is methane, which is the product of the vital activity of microorganisms. Therefore, for the extraction of biogas, a nutrient mass is required in which bacteria can multiply. As raw materials you can use:

- vegetable waste;

- wastewater;

- bird or animal manure.

If you select any raw material, the coefficient and rate of gas production will vary. Shredded vegetation rots for a long time and gives a small amount of biogas, wastewater is more suitable for diluting the bulk, but excrement is able to produce combustible gas on the second day after the start of use.

How it works

To make it easier to understand how biogas plants work, you can watch a video made by craftsmen. However, the entire gas production process can be briefly described and decomposed into several stages:

To make it easier to understand how biogas plants work, you can watch a video made by craftsmen. However, the entire gas production process can be briefly described and decomposed into several stages:

- reactor loading;

- waiting for synthesis;

- gas collection and storage.

During loading, the biomass should be thoroughly mixed, and the fermentation tank must be airtight. The time for producing blue fuel can be reduced if the reactor is insulated, and it is better that it be heated. For collection and storage you will need high-quality cylinders and hoses, because safety in gas production cannot be neglected.

The necessary conditions

Owners of a biogas-producing system note the high efficiency of its work. However, there are 3 conditions that must be met in order for the installation to be useful.

- Despite the size of the proposed biogas plant, it will require a dedicated space. For a small gas production system, a garage or a barn may well be suitable, but installations that can completely heat a house will require a lot of space. Often, in order to save usable area in a private area, the tanks are dug in the open.

- Before constructing a biogas plant, it should be understood that it needs constant monitoring. This is not to say that it will be necessary to tirelessly be near the system, but in order to avoid the dangers of an accidental gas release, the installation must be monitored occasionally. For long departures, it must be cleaned, and the tanks must be opened.

- To begin the construction of a biogas plant for home heating or cooking, you should calculate the amount of raw materials available. If biomass will be purchased, then you need to make sure that the raw materials are always available, since insufficient mass volume significantly reduces production.

What is required for a biogas plant

The construction of the simplest reactor does not require special equipment. Handy materials can be used. Here is a list of necessary things:

The construction of the simplest reactor does not require special equipment. Handy materials can be used. Here is a list of necessary things:

- fermentation tank;

- reliable hoses or tubes;

- sealed fuel storage tank;

- valves

- filter (required).

When a biogas plant is being built for heating a house, a more complex production system is required, with gearboxes, an engine for pumping gas, a mixing device, biomass heating and tank insulation.

The simplest installation principle

For a simple biological gas production system, a barrel can be used as a reactor. However, it must be clean. Do not use containers that contain toxic particles, such as dyes or toxins. This can reduce the vital activity of microorganisms to zero.

For a simple biological gas production system, a barrel can be used as a reactor. However, it must be clean. Do not use containers that contain toxic particles, such as dyes or toxins. This can reduce the vital activity of microorganisms to zero.

The barrel should be hermetically sealed, but it requires openings for loading biomass, pumping gas and removing waste material. To simplify the task, it is possible to draw a universal conclusion, which will allow for all manipulations. First, biomass diluted to kefir density is poured through this hole. Later, it can be screwed up with a tube removed for gas.

The gas outlet from the barrel should pass through the filter, because the biological mass emits up to 10% of hydrogen sulfide, which is harmful, and 35% of carbon, which impairs the combustible properties of methane. For a filter from hydrogen sulfide, a flask with metal chips can be used, and in order to remove carbon, a liquid solution with hydrated lime is suitable.

After passing through the filters, the gas must enter the storage tank. For this purpose, a container of large volumes is suitable, in which it is necessary to place the collector, it is also a container for saving blue fuel. As a collector, tight sealed polyethylene or an old car camera is suitable.

Multifunctional system

Making a multifunctional biogas plant for a private house with your own hands will be not much more difficult than a simple device, but such a voluminous system will take up more space.

Reactor

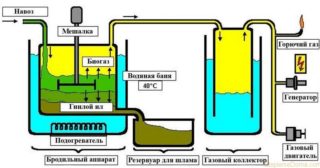

In order for biogas to suffice for heating and maintenance, a reactor is required, the capacity of which is capable of holding 300 kg of raw materials. It should be borne in mind that biomass is loaded only on 2/3 of the tank volume. The free space of the reactor is necessary for the normal course of fermentation processes. In addition, it is advisable to equip a large reactor with heating.

Heating

For heating, the reactor is placed in a container with water, where the electric heating elements are located.

Compressor

When using a large biogas plant, it is better to collect gas in cylinders. For this, it is convenient to use a compressor that is connected to the outlet of the gas that has passed through the filter.