Heating cottages and private homes outside of cities can be a significant problem. Combined boilers for heating a home are an advantageous solution to a difficult situation. Complex devices with several circuits will provide a given temperature regime throughout the room, regardless of the type of fuel.

Basic types of boilers

All boiler models, regardless of energy consumption, are divided into two main groups:

All boiler models, regardless of energy consumption, are divided into two main groups:

- Universal category. The options for the fuel used are not limited.

- Standard boilers. Heat is generated from one type of coolant.

Combined equipment focuses on work from electric networks and various solid fuel or gas systems.

To heat water in the summer, many complex boiler models are equipped with electric heaters without involving the main heating elements.

A wide range of equipment is represented by options with a complete set of hobs, two circuits with separate burners of different types of control. The presence of additional functions improves the quality of the resources used, but complicates installation work, commissioning.

Features of hybrid designs

Reviews of owners of private houses or cottages with combined installations indicate the presence of qualitative advantages of such systems, especially if the housing is far from the wiring of the centralized gas supply and there are power outages. Modules with a mechanical control make it possible to transfer the boiler to manual mode without losing functionality.

Reviews of owners of private houses or cottages with combined installations indicate the presence of qualitative advantages of such systems, especially if the housing is far from the wiring of the centralized gas supply and there are power outages. Modules with a mechanical control make it possible to transfer the boiler to manual mode without losing functionality.

Boiler installations are endowed with many advantages:

- connection of several separate circuits at the same time;

- have a solid combustion chamber, or several fireboxes for different types of energy carrier;

- the ability to connect a suspended gas burner;

- equipped with electric shades for backup heater and hot water supply;

- a new level of use of program management;

- the gas burner is structurally replaced with another energy source;

- alternative programmable switch to spare fuel.

Different levels of automation devices in combined boilers for heating houses allow you to be on a par with electric and gas models.

Opportunities to combine fuel compositions

Heating systems must be designed for emergency situations when one energy source is urgently replaced by another. The market offers equipment for several types of fuel. Consider complex heating boilers using several fuel functions that do not require a radical change in the system. The proposed heating devices are able to provide the consumer with hot water not only in private homes, but also in office buildings or communal organizations.

Combination of firewood - gas

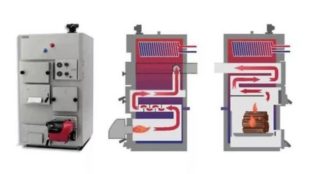

Coal, firewood, briquettes, lumber - everything that can be burned is suitable for the furnace module. The installation consists of one or two separate cameras. In the fixture with the furnace, only solid materials are used at a time; a burner is mounted to transfer gas to the chamber.

Coal, firewood, briquettes, lumber - everything that can be burned is suitable for the furnace module. The installation consists of one or two separate cameras. In the fixture with the furnace, only solid materials are used at a time; a burner is mounted to transfer gas to the chamber.

Devices with separate fire chambers have impressive dimensions. Two types of energy resources can be used simultaneously. The heat exchanger is mounted one on 2 chambers or a combination of two separate elements is present.

Gas / solid fuel plants are relatively inexpensive and are in high demand among owners of small cottages.

The combination of gas - electricity

Quite common combined boilers are installed in places with a centralized gas supply. Advantages of heating boilers of this type:

Quite common combined boilers are installed in places with a centralized gas supply. Advantages of heating boilers of this type:

- The small sizes. A heat exchanger with a built-in heater is installed in a relatively small combustion chamber to provide hot water.

- Economical power consumption. The thermocouple is switched on only if it is necessary to quickly heat the water, or in the summer without turning on the gas in the heating system.

- Low price for the lineup.

In varieties of equipment, with the absence of a secondary circuit, an additional water heater is installed. In case of interruptions in gas supply, shadows with low power will be able to maintain a minimum coolant temperature.

Combined heating devices are equipped with all the safety devices necessary for each energy carrier. Leakages are regulated by gas analyzers, and a reduced risk of electric shock provides grounding. Sensors for the presence of traction, combustion products in the air and so on are installed.

The combination of firewood - electricity

Solid fuel boilers are installed if it is impossible to connect to the main gas pipeline, fuel in cylinders. They are non-volatile and have high power. Factory-made universal devices are equipped with all safety protection elements with a manufacturer's warranty.

Solid fuel boilers are installed if it is impossible to connect to the main gas pipeline, fuel in cylinders. They are non-volatile and have high power. Factory-made universal devices are equipped with all safety protection elements with a manufacturer's warranty.

Features of heating units using a combination of firewood / electricity:

- serviceability - electrical system parts are easy to replace;

- design reliability - heating elements are designed to work in the furnace;

- a temperature controller provides remote temperature control.

To adjust the power of solid fuel boilers, manufacturers recommend installing and using electronic heat controllers.

Multi-fuel heating equipment

Equipment for domestic use performs its functions on several energy carriers. In addition to the most common combinations with gas heating, firewood, electricity, the device burns pellet pellets. In variations of boiler units with a pellet feed hopper, this structural element is removed, and the chambers are used for certain energy sources. Units are adapted for different fractions of fuel, therefore, it is necessary to take into account the creation of special conditions for increased injection pressure, forced traction.

Equipment for domestic use performs its functions on several energy carriers. In addition to the most common combinations with gas heating, firewood, electricity, the device burns pellet pellets. In variations of boiler units with a pellet feed hopper, this structural element is removed, and the chambers are used for certain energy sources. Units are adapted for different fractions of fuel, therefore, it is necessary to take into account the creation of special conditions for increased injection pressure, forced traction.

The functionality is expanded by installing an electric heater in a heat exchanger.

To install multi-fuel systems, the following requirements must be met:

- during continuous operation, it is necessary to ensure the supply and storage of energy;

- organization of delivery of consumables to the boiler;

- uninterrupted supply to electric power units.

When choosing combined boilers for heating a house, an analysis of factors for a particular room should be carried out. The main indicator is economic feasibility. In addition to the increased cost of the device, it is necessary to take into account the additional costs of matching the diameter of the chimney for each fuel material with the presence of the served area.

It makes no sense to buy a powerful boiler for small spaces with the hope of a good automation. This approach attracts unused capacity, leading to rapid wear of equipment in conditions of "idle" operation of the system.