Laminate flooring requires preparation of the base. In addition to leveling concrete or other material, you need to think about the type of insulation and the creation of a barrier to moisture, which can spoil the finishing wood slab. Expanded polystyrene under the laminate solves these two problems and, in addition, it is a kind of damper, reducing the load on the coating when walking.

What types of polymer are

On an industrial scale, there are three main technologies for the production of polystyrene canvases with the production of a product that is different in performance:

- method of obtaining a mold without press;

- use of special press equipment;

- receiving material in the installation of the extruder.

Any of the methods allows you to get a quality product, designed to perform certain tasks of thermal insulation.

Pressless polymer product

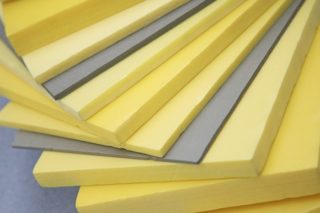

By non-pressurized understand expanded polystyrene, consisting of granules of the same diameter, tightly interconnected under the influence of a thermal process. The density of the structure determines the strength of the product and is from 50 to 15 kg per cubic meter. The product is marked with the abbreviation PSB with numbers at the end that indicate hardness. The product can be used as insulation for walls and roofs of buildings, various metal containers, and as polystyrene foam for laminate floors.

High-quality plastic is easily distinguished from low-quality by breaking the sheet and checking the diameter of the grains - grains of different sizes indicate a fake.

Extruded polystyrene foam

PS is a product that is manufactured on press equipment by compaction of latex grades of raw materials using blowing agents. The structure of such plastic consists of closed cells. The main characteristics of the polymer structure:

- lack of electrical conductivity;

- low water absorption;

- heat retention;

- blocking the passage of sound waves;

- unsuitability for the development of pathogenic flora.

The press polymer structure can be used in radio engineering, as it is transparent for the passage of radio waves.

Extruded Material

In the manufacture of an extruded polymer structure (EPS), the raw materials are melted in an extruder and then filled with a mold. The hardened mass has homogeneous cells and is almost completely waterproof. In addition, operational performance with regards to mechanical loads is much higher than that of any other similar polymers. The product can be used for any insulation purposes, including as a substrate for a polystyrene laminate.

There are fire-resistant EPS brands made with flame retardants added to the structure.

Extruded polymer sheet fabrication

The process of obtaining the polystyrene substrate web undergoes the following process steps:

- The granules are mixed with dye, illuminator and flame retardants (if necessary).

- The granules are subjected to foaming, followed by aging for a certain time.

- Raw materials are placed in an extruder, where it is heated and sintering takes place.

- Through the nozzle of the heating box, the viscous mass is fed to a special drawing device.

- The resulting fabric is subjected to cooling in vivo or forced.

- The following is the process of stabilizing and grinding the surface.

- In the last step, the expanded polystyrene foam for the substrate is cut into sheets and packaged.

The brand of the material obtained depends on the amount and type of additives that are added to the main composition at the first stage of the technological process.

Types of flooring substrates

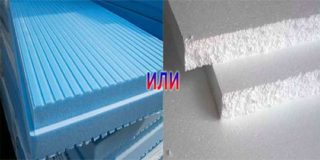

As a heater, not every polystyrene plate is suitable for a laminate. There are several types of this product designed specifically for such purposes. Between them, their difference is in operational characteristics and in the thickness of the working layer. The ends of the joints are straight and with special grooves obtained by milling. In this way, the processed edges allow you to tightly align the joints, avoiding gaps.

On sale you can find plastic in the form of rolls or single sheets.

Two millimeter material

A polystyrene foam backing of this type has a density of about 40 kilograms per cubic meter. It is permissible to use this thickness in a heating system underfloor heating, provided that the sheets have special perforation for the unhindered penetration of warm air to the surface of the floor. The disadvantage of the material is the inability to level the base under the laminate due to the small thickness, which must be compensated for by a more thorough preparation of the concrete screed.

Three millimeter backing

In terms of performance, the polymer has a higher level of density and durability. It is able to withstand a load of 45 kilograms per cubic meter. Specialists in laying note the best ability of the material in terms of leveling the unevenness of the base of the floor. On the market, a three-millimeter polystyrene backing can be found in roll design and in the form of an accordion made of sheets.

Five millimeter insulation

Polystyrene sheet on the floor under the laminate with a thickness of 5 mm has higher thermal insulation performance than a similar one in 3 mm, about 2%. In addition, it is able to effectively smooth out small irregularities on concrete and other substrates.

In order to avoid the accumulation of dampness directly under the insulation, it is recommended to pre-cover the concrete screed with a vapor barrier layer.

Styling technology

The main condition for organizing the substrate is that the joint between the sheets or rolls of the polymer does not coincide with the joint of the laminate or parquet boards. This is achieved by laying the insulation at an angle to the finish by about 45 degrees. The rest of the technology boils down to the following steps:

- Dirt and a small fraction of debris are removed from the concrete surface.

- The screed is covered with a vapor barrier.

- The polymer structure is stacked in a checkerboard pattern.

In order not to trample the surface, you can put the insulation in parts over the width of two stripes of the board.

How to choose a manufacturer

A high-quality substrate for polystyrene foam for work on the improvement of the floor surface can be selected based on the following considerations:

- The manufacturer of polymer materials should be well known among consumers.

- A wide range of products, several brands of extrusion polymer structure should be presented on the market under a specific brand.

- Upon request for each type of product, the plant manager or retailer is required to provide a certificate of compliance and a full package of documents.

Ultimately, in addition to high performance, the insulation must be safe for human health.