High-quality thermal insulation makes the house comfortable and cozy, reduces heating costs. Choosing a heater with suitable performance, many buyers prefer foam. It reliably protects from the cold, safe for health, easy to install. It is important for residents of apartments to know whether it is possible to insulate with penoplex indoors. By construction standards, this is allowed, the main thing is to observe the technology of installing thermal insulation.

Characteristics of foam

Extruded polystyrene foam (EPS) or foam foam is a Russian-made insulation. Thermal insulation material is made on the basis of synthetic raw materials by extrusion. The molten composition is pressed through holes, then molded. Production technology provides the density and closed structure of the material cells. Manufacturers offer 4 types of extruded polystyrene foam, characterized by properties and purpose:

- Roofing - material for thermal insulation of all types of roofing.

- Wall - plates for insulation of external and internal enclosing structures.

- Comfort - a universal heater for interior use.

- Foundation - products with high density for loaded areas, are used under the screed.

The plates are the same orange, but have external design features. Stripes are applied to the wall material to improve adhesion to the base. Comfort insulation has a L-shaped edge, which reduces heat loss at the seams.

The main characteristics of EPSP:

- The dense structure of the plates provides low water absorption - up to 0.5% in 28 days.

- The coefficient of thermal conductivity of 0.03 remains unchanged throughout the entire period of operation.

- The vapor permeability is low - 0.007-0.008, the material does not allow water vapor.

- Sound insulation when using a plate with a thickness of 50 mm is 41 dB.

- Service life of 50 years.

- Combustibility class - G1-G4. The insulation used for interior and exterior decoration is made with the addition of flame retardants. Foundation materials are not protected against fire.

- Operating temperature from -50 to + 75 ° C. Penoplex is not used in areas where a temperature increase above 80 ° C is possible.

EPSP has no harmful secretions. When using the material, you can not worry about the negative impact of thermal insulation on the health and well-being of people. It does not cause allergies and other negative reactions. The material is not affected by mold and mildew. The shape of the insulation makes it easy to calculate the material, it is convenient for installation. Plates are easily cut with a construction knife, do not crumble.

Pros and Cons of Material

Penoplex is a synthetic material made from polystyrene. It is available in 600 × 1200 mm plates of various thicknesses. There are 5 types of foam: 31, 31C, 35, 45 and 45C. They have different density and strength, while the thermal conductivity remains unchanged. The indicator is not affected by humidity or temperature. This is the main plus of the insulation. In addition to excellent insulating properties, other advantages of EPSP can be distinguished:

- The material is resistant to biological effects, freezing and temperature fluctuations.

- Plates have high strength indicators, withstand a significant load.

- The ease of installation allows you to do penoplex insulation of the walls inside the house with your own hands.

- Extruded polystyrene foam is not afraid of exposure to chemical compounds - bitumen, cement mortar, lime, plaster.

- Insulation for walls inside houses penopleks is environmentally friendly.

- The minimum rate of water absorption allows you to use the material in high humidity conditions without additional waterproofing.

- EPPS protects against cold and prevents the spread of noise. The porous structure makes it a good sound insulator.

- The insulation has a long service life of at least 50 years. The specified parameter is not the limit, the material does not deteriorate even after half a century.

- The light weight of the plates does not burden the structure, simplifies transportation and unloading.

Cons of insulation are:

- Low UV Resistance. Even during storage, the boards need protection. They are sold packaged in plastic wrap. When using penoplex for thermal insulation of buildings from the outside, finishing is required.

- Extruded polystyrene foam is damaged by solvents, oil products, oil paints.

- Some brands of insulation have a combustibility class G4, this means low fire safety. It is not necessary to insulate ceilings with high combustibility foam, it is better to pay extra for material with the addition of flame retardants.

- The smooth surface of the boards has low adhesion, which makes installation on the ceiling and walls difficult.

The cost of foam is higher than polystyrene and mineral wool. But the excellent performance characteristics of the material ensured its popularity as a heater.

Application area

The characteristics of the heat insulator provided ample opportunities for its use. Penoplex is used at all stages of construction, starting with laying the foundation. The scope of the material is not limited to buildings:

The characteristics of the heat insulator provided ample opportunities for its use. Penoplex is used at all stages of construction, starting with laying the foundation. The scope of the material is not limited to buildings:

- isolation of pools, utilities, wells, storage tanks;

- basement insulation and blind areas of private houses;

- use for a flat roof with reinforced concrete slabs for roll roofing;

- thermal insulation of the pitched roof, attic, attic, balcony or loggia;

- insulation of the ceiling with foam, as well as floors and partitions;

- wall insulation of residential buildings, garages, warehouses, industrial facilities;

- used in the construction of the runway of the airfield.

Before buying material, you must check the certificates of conformity. Conscientious manufacturers always supply products with the necessary documents. Their absence indicates a low quality product. Such a heater is made in violation of standards and GOSTs.

Work sequence

Thermal insulation of a house, garage or bath is an objective necessity. After installing the insulation, heating costs are reduced, and the room temperature remains stable. Placing the heat insulator on the outside avoids condensation, problems with dampness and reduced space.

It is not always possible to insulate a panel or frame house from the outside. Residents have to insulate the walls of the house from the inside with foam. Material in its properties is suitable for interior use. To do the work, you can hire builders or do the installation of plates and finishing the apartment yourself.

Preparatory Activities

At the preparation stage, the necessary materials are procured. To complete the work you will need:

- Plate foam in the estimated amount, plus a small margin for trimming.

- Special adhesive for extruded polystyrene foam, sold as a dry mix.

- Construction foam for insulation of joints between plates.

- Fiberglass reinforcing mesh for plaster.

- Plastic dish-shaped dowels for fixing the insulation - 5 pieces per plate.

- Dry plaster mix.

- Finishing materials - drywall, wall paneling.

For thermal insulation of concrete and brick walls, vapor barrier is required. For high-quality surface preparation, a primer is acquired.If finishing with sheets of drywall is provided, you need to buy wooden slats or a metal profile to collect the frame.

Tools

At the preparatory stage, the necessary tools are collected:

- drill with nozzle mixer;

- hacksaw;

- sandpaper grater or needle roller;

- construction level (bubble, laser);

- hammer;

- hammer drill;

- notched trowel.

To mount the slabs on the ceiling, it is recommended to install scaffolding.

Surface alignment

Before starting repair work, it is necessary to prepare the surface of the walls and ceiling for fixing the insulation. To improve adhesion, the remains of cement mortar, old finish are removed. The design is cleaned of dust and dirt. Using the level, the base plane is checked. If slopes are noted, leveling with plaster is necessary. Also, putty mortar close up cracks and holes in the wall. Heat insulation is started after the solution has dried.

The prepared surface is treated with a primer. The composition penetrates the layers of plaster, preventing the development of mold. Also, the primer improves the adhesion of the insulation to the walls and flow. After the composition dries up, the main work begins.

Insulation Installation

Plates of foam plastic are laid on an insulated surface according to glue or combined technology. In the second case, they are additionally fixed with dish-shaped dowels. To fix the plates, special glue is used, which is diluted before starting work. The surface of the foam is passed with a grater or needle roller to reduce smoothness. The solution is applied to it with a notched trowel. Depending on the scale of the insulated surface, the adhesive is distributed along the entire plate or along the perimeter and middle.

The insulation is mounted by the frame or frameless method. Under the drywall or wooden lining, the frame is assembled from wooden blocks or special guides. Installation begins with the marking of the ceiling, then the lines are transferred to the walls. The guides are attached in increments of 600 mm - this is the width of the foam boards. When using wooden blocks, the material is pre-treated with an antiseptic. The heat insulator will fit snugly between the crate. Frameless method less costly and time-consuming. Finishing material is attached directly to the insulation.

To the walls

The installation technology of foam plastic depends on the material of the walls. For concrete structures that do not have external insulation, the use of vapor barrier is recommended. Freezing the walls will cause condensation and constant dampness. In wooden houses, this problem does not arise.

Laying the insulation starts from the bottom corner. In each next row, it is desirable to move the slabs half the width. Checkerboard mounting reduces the seam length. Mounting to the wall occurs using various compositions:

- Bituminous mastic - used as a fixative and waterproofing in rooms with high humidity.

- Cement based mineral glue is the most common option. The composition hardens quickly, so it is kneaded in small portions. Thorough mixing is required until the solution is homogeneous.

- Polyurethane adhesive in cans - easy to use, one package is enough for 12-15 square meters. m

- Polyurethane foam - a universal composition will provide reliable adhesion with brick, concrete, aerated concrete. Foam dries quickly, creates an airtight seam.

Penoplex with adhesive applied tightly pressed against the wall and held for 40-60 seconds. Plates for reliability are fixed with 5 dowels, fasteners clog in the corners and center.

To get a flat surface, periodically apply a bubble level to the thermal insulation.By increasing or decreasing the adhesive layer, the plane can be adjusted.

The gaps between the foam are filled with foam. After drying, the protruding parts are cut off. When warming with the frame method, the plates are laid in a similar way.

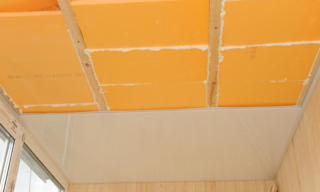

To the ceiling

The ceiling is insulated from the inside or outside. In a private house, to reduce heat loss, penoplex is laid on the floor of the attic. Fixation occurs on the adhesive. Boards are mounted on top of the insulator on the crate. In apartments this is not possible, so the insulation is made from the inside. The surface is prepared just like walls - it is cleaned, leveled and primed.

Glue is applied to the surface of the plates, then they are firmly pressed to the ceiling. Fixing with dowels reliably fixes a heater. If a frame is provided, the foam is placed between the rails. All seams are filled with construction foam.

Finish finish

After the adhesive solution has completely dried, the final finishing is started. The first step is to apply reinforcing plaster. This will require putty, you can use a mineral adhesive. A reinforcing mesh is placed on the wet solution layer. On top of it, another layer up to 3 mm thick is applied. After drying, the finishing putty remains, which is the basis for tiling or wallpapering.

If drywall installation is provided, plastering is not required. After the glue has dried, the GKL sheets are screwed to the frame with screws, the fastening step is 30 cm. The joints of the sheets and the places where the hats of the screws are recessed are putty using reinforcing tape. Finishing gypsum putty is applied with a thin layer, carefully sanded. The final stage is wallpapering.

The excellent heat and sound insulation properties of the foam made it a popular heater. The material is safe for health, so it can be used for internal work. Simplicity and speed of installation allow you to do the work on your own.