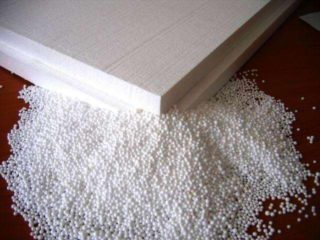

The initial form of polystyrene foam is granules. They can be used for molding products - plates, sheets, films - or used in their original form. Expanded polystyrene granules are very light, flowable, small in size and have excellent thermal insulation properties.

Features and properties of expanded polystyrene granules

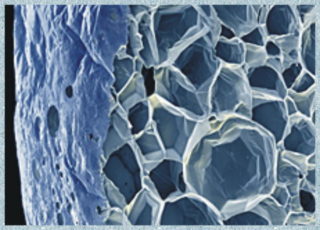

The raw material for the granules is styrene and its copolymers. The material itself is also a heat insulator, but not so outstanding. But if the polymer melt is saturated with gas and a blowing agent is added, the polystyrene particles expand in volume, fill with air and form light granules that are not connected to each other.

Particles have a regular spherical shape. Sizes range from 1 to 8 mm. Small particles are used for stuffing toys, large for thermal insulation. The surface of the granules is smooth and dense. They weakly adhere to each other and in volume possess such property as fluidity.

Granules can be obtained in another way. Solid polystyrene foam is crushed to the starting particles. In this case, part of the granules is destroyed, part is deformed. The resulting material is called crushed chips or crushed. Its characteristics are worse: if the integrity of the sphere is violated, the material absorbs water more strongly, contains less air, and therefore saves heat worse.

Granular polystyrene foam, having all the qualities of a slab, has some features. They are associated with the flowability of the material:

- Soundproofing properties - there are no rigid bonds between particles, the material cannot reflect sound, as it has an unstable structure. In addition, with free filling between the granules, air cavities of different sizes and shapes remain, which also contributes to the absorption of noise.

- Spheres filled with gas have elasticity. With mechanical action, they change shape and restore it after the load disappears.

- Loose polystyrene foam can take any form, change it under pressure and restore. This property is widely used in furniture manufacturing. Granular lightweight polystyrene foam is used for stuffing pillows, chairs, armchairs, and for the manufacture of frameless furniture.

- The density of the granules coincides with the density of the tile material obtained from them. The pattern is the same: the higher the density, the heavier the material, the stronger it is and the less it absorbs moisture. However, with an increase in density, the insulating qualities decrease, so too strong polystyrene is not released.

Another indicator of granular polystyrene foam is bulk density, from 8 to 40 kg / cubic meter. The smaller the granules in size and the denser they are, the higher this parameter.

Advantages and disadvantages

Granular foamed polystyrene has the advantages of the polymer itself and the structure of the mixture. The most important are the following:

- Polystyrene granules include numerous pores filled with air. By the level of thermal insulation, the material exceeds the performance of concrete by 30 times, hollow clay bricks - by 7 times. Since the granules are spherical in shape, they do not fit snugly together - cavities filled with air also form between the particles themselves. Polystyrene granules increase thermal insulation properties even when added to concrete.

- The polymer is not susceptible to mold and mildew. For rodents, it is also not of interest.

- Granular polystyrene foam is chemically inert, does not collapse under the influence of household chemicals.

- The pellet shell is sufficiently dense, they do not swell and do not absorb water. Loose polystyrene foam dries with not too much wetting with water.

- Expanded polystyrene in round granules exhibits higher soundproofing properties.

- Unlike slab expanded polystyrene, loose passes air. Such a heat insulator “breathes” and does not provoke moisture condensation.

- The heat insulator retains its characteristics in the range from -80 to +75 C.

- 1 cc m. crumbs weighs from 15 to 30 kg. Thermal insulation does not constitute a load on the walls or foundation.

- Polystyrene insulation lasts up to 80 years.

- Styrofoam is noticeably cheaper than a plate heat insulator.

The disadvantages of polystyrene are inherent in all organic polymeric materials:

- The polymer is flammable, therefore it can only be used for external insulation or as a filler inside walls. Self-extinguishing material is also used for internal work: here the polymer attenuates if it is removed from the combustion site.

- When burned, polystyrene releases toxic substances. Is it dangerous.

Granular polystyrene is produced in different densities. Strength, thermal insulation properties depend on this indicator.

Release Forms

The feedstock - polystyrene, has a low density, in the range of 1060 kg / cubic meter. However, the foamed version has an even lower density, so it is used mainly for insulation. Offer it in 2 forms.

In loose form

By treating the polymer with gas and blowing agent, spherical particles with a very low density are obtained. The granules are cooled and dried, and then packed in bags. By size, the particles are divided into fractions. For different purposes, granules of different diameters are required.

In molded products

It is based on the same polystyrene in round granules. Finished particles are not dried, but transferred to a form where, under the influence of temperature or temperature and pressure, they sinter, forming a single whole. The cellular structure is preserved.

This option is more convenient with external thermal insulation. Also, complex shapes can be cut out of plates to warm any structures.

Application area

Granular polystyrene foam is used in various fields:

- Thermal insulation - most often granules are poured into the cavity between the walls. Also with their help they insulate the foundation, floors, attics.

- In the manufacture of expanded polystyrene concrete, foam crumb is added to the concrete solution. Such material retains heat better.

- During the construction of pontoons, cavities are filled with polystyrene chips.

- In sewage treatment plants, granules act as absorbents and purify liquids.

- Particles are used as a filler in frame and frameless furniture.

- Apply material in the field of design. Artificial snow is made from crumbs.

For internal thermal insulation work, only self-extinguishing polystyrene foam is allowed.

Popular manufacturers

Granular polystyrene foam is offered by many manufacturers:

- LLC Energoprommashina from Yekaterinburg - makes the most different brands of polystyrene. Price is 1 cubic meter. m. from 1100 p.

- The company "Logistics Logistics Construction" offers expanded polystyrene, packed in packages of 0.6 cubic meters. m. for 830 p.

- Plant Plastrom LLC produces self-extinguishing foam for 2000 r. for 1 cube m

- LLC Teply Dom in Orenburg produces a crusher for 1100 p. for 1 cube m

Acquiring material is not difficult. Its cost is slightly higher in large cities. More significantly the price is affected by the brand, density, fraction, treatment with flame retardants.